Liquid-solid composite forming copper-clad aluminum bus duct busbar and manufacturing method thereof

A composite forming, copper-clad aluminum technology, applied in the direction of cable/conductor manufacturing, root rod/rod/wire/strip conductor, circuit, etc., can solve the unstable electrochemical and mechanical properties of horizontal continuous casting method, crimping method Unstable quality of craft products, inconvenient installation and maintenance, etc., to improve production efficiency and automatic production level, good plasticity, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

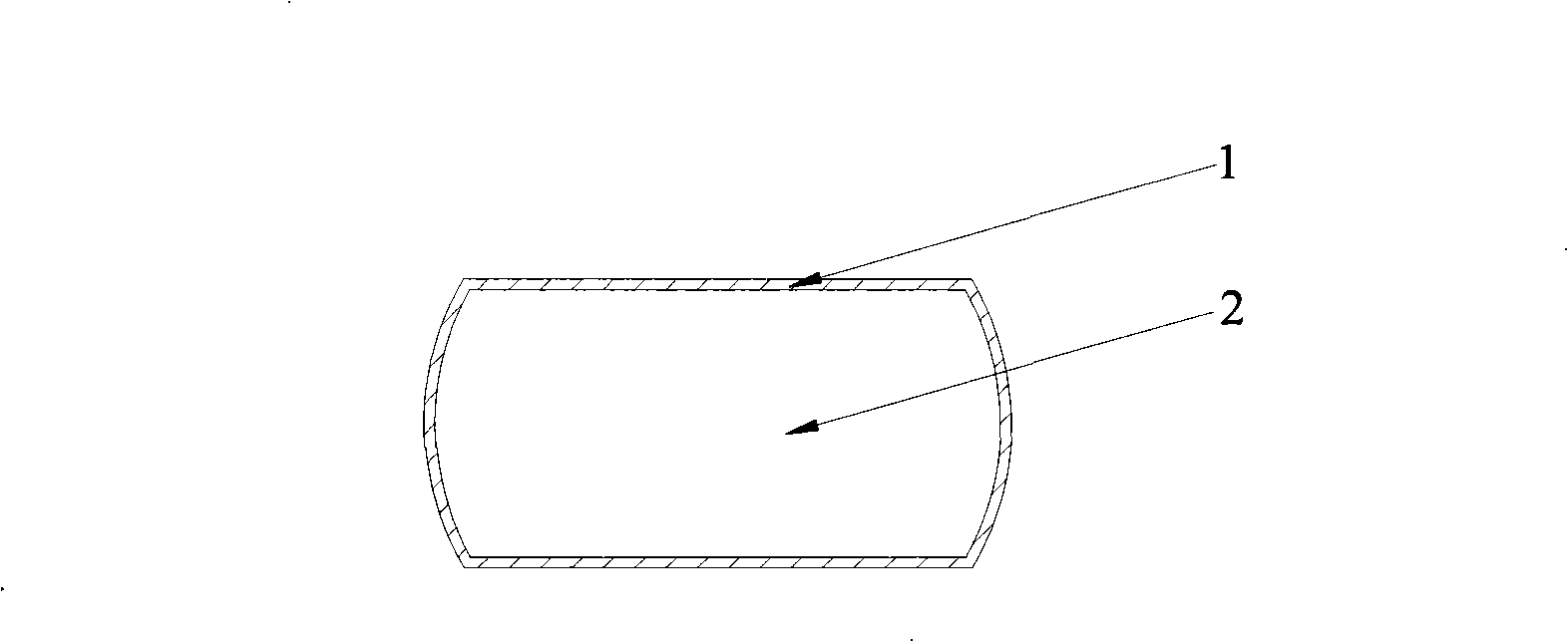

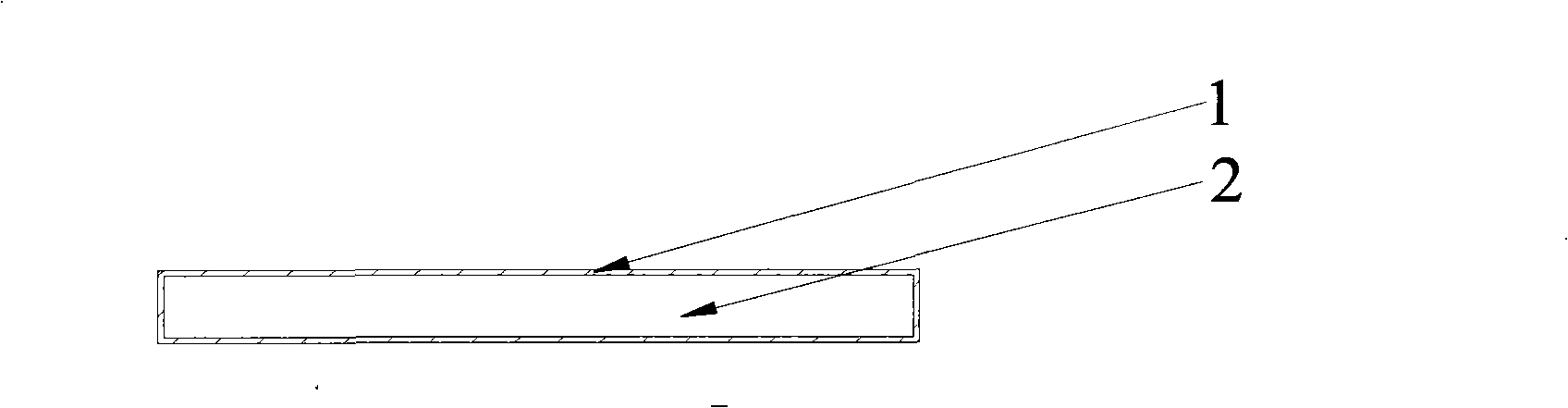

[0020] Example 1: If figure 1 As shown, it is a schematic cross-sectional view of extrusion casting billet for copper-clad aluminum busway conductive bar. The shape of the billet is rectangular in the middle, and the two ends of the rectangle are arc-shaped; figure 2 It is a cross-sectional schematic diagram of the extruded copper-clad aluminum busway conductive bar, and the final shape of the product is a rectangle.

[0021] Copper-clad aluminum busway conductive bar section size: section length 50mm, section width 6mm. The production process consists of the following steps:

[0022] 1) First, the ingot is manufactured by extrusion casting, and the special-shaped copper tube is subjected to chemical pretreatment (including degreasing-cleaning-neutralization-cleaning-passivation-cleaning-drying), and placed in the extrusion casting mold. Preheat at 400°C; at the same time, the pure aluminum is smelted, the temperature of the molten aluminum is 700°C, refining treatment, sta...

example 2

[0026] Example 2: If figure 1 As shown, it is a schematic cross-sectional view of extrusion casting billet for copper-clad aluminum busway conductive bar. The shape of the billet is rectangular in the middle, and the two ends of the rectangle are arc-shaped; figure 2 It is a cross-sectional schematic diagram of the extruded copper-clad aluminum busway conductive bar, and the final shape of the product is a rectangle.

[0027] Copper-clad aluminum busway conductive bar section size: section length 60mm, section width 9mm. The production process consists of the following steps:

[0028] 1) First, the ingot is manufactured by extrusion casting, and the special-shaped copper tube is subjected to chemical pretreatment (including degreasing-cleaning-neutralization-cleaning-passivation-cleaning-drying), and placed in the extrusion casting mold. Preheat at 450°C; at the same time, the pure aluminum is smelted, the temperature of the molten aluminum is 750°C, refined, let it stand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com