Preparation method of high-density non-ball shape ferric phosphate powder body

An iron phosphate powder, non-spherical technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of complex process, harsh process conditions, large particle size of spherical particles, etc., to improve the volume specific capacity, the process is simple and controllable , the effect of high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] (1) Solution preparation, preparation 1..0mol.dm -3 Fe(NO 3 ) 3 .9H 2 O and H 3 PO 4 Mixed aqueous solution (Fe:P molar ratio 0.9:1.0).

[0011] (2) Put the above-mentioned mixed solution into a reactor, set the reaction temperature at 50° C., gradually add ammonia solution (the concentration of ammonia water is 25%) under stirring until the pH value of the reaction solution reaches 1.5, and then continue to react for 2 hours to obtain Iron phosphate slurry.

[0012] (3) Pour the slurry into a plate-and-frame filter press, and keep the pressure at 0.5Mpa for 10 hours to obtain a filter cake.

[0013] (4) The filter cake was dried at 120° C. for 8 hours, and then washed with water to remove soluble impurity ions.

[0014] (5) Dry the cleaned material again at 120°C, then crush and sieve to obtain hydrated ferric phosphate powder with a tap density of 1.55g.cm -3 .

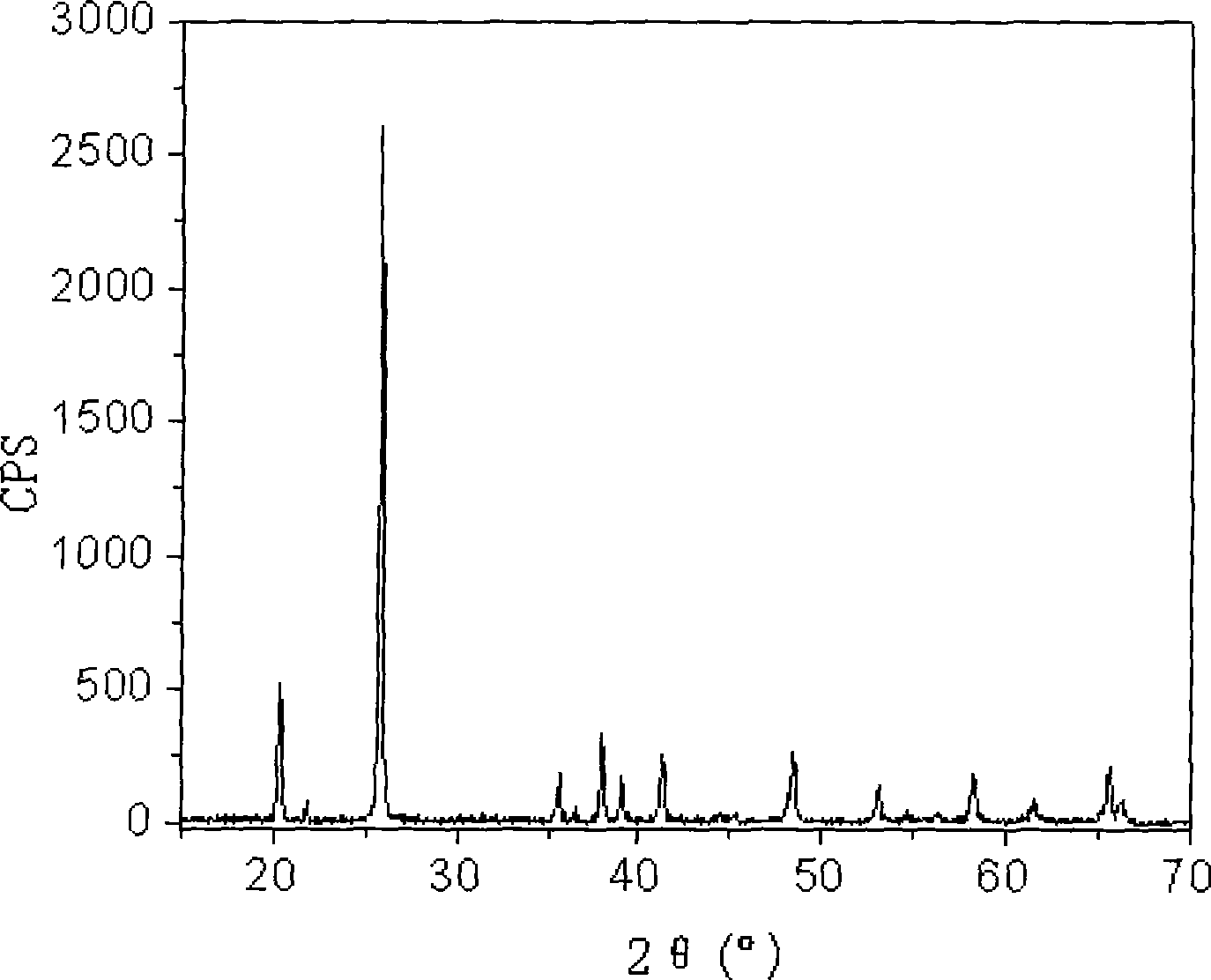

[0015] (6) Sintering the hydrated ferric phosphate at 550° C. for 8 hours to obtain anhydrous fer...

Embodiment 2

[0018] (1) Solution preparation, preparation 2.0mol.dm -3 Fe 2 (SO 4 ) 3 and H 3 PO 4 Mixed aqueous solution (Fe:P molar ratio 0.9:1.0).

[0019] (2) Put the above mixed solution into a reactor, set the reaction temperature at 70°C, gradually add ammonia solution (the concentration of ammonia water is 12.5%) under stirring until the pH value of the reaction solution reaches 2.5, and then continue to react for 2h to obtain Iron phosphate slurry.

[0020] (3) Pour the slurry into a plate-and-frame filter press, and keep the pressure at 0.8Mpa for 5 hours to obtain a filter cake.

[0021] (4) The filter cake was dried at 130° C. for 6 hours, and then washed with water to remove soluble impurity ions.

[0022] (5) Dry the cleaned material again at 100°C, then crush and sieve to obtain hydrated ferric phosphate powder with a tap density of 1.45g.cm -3

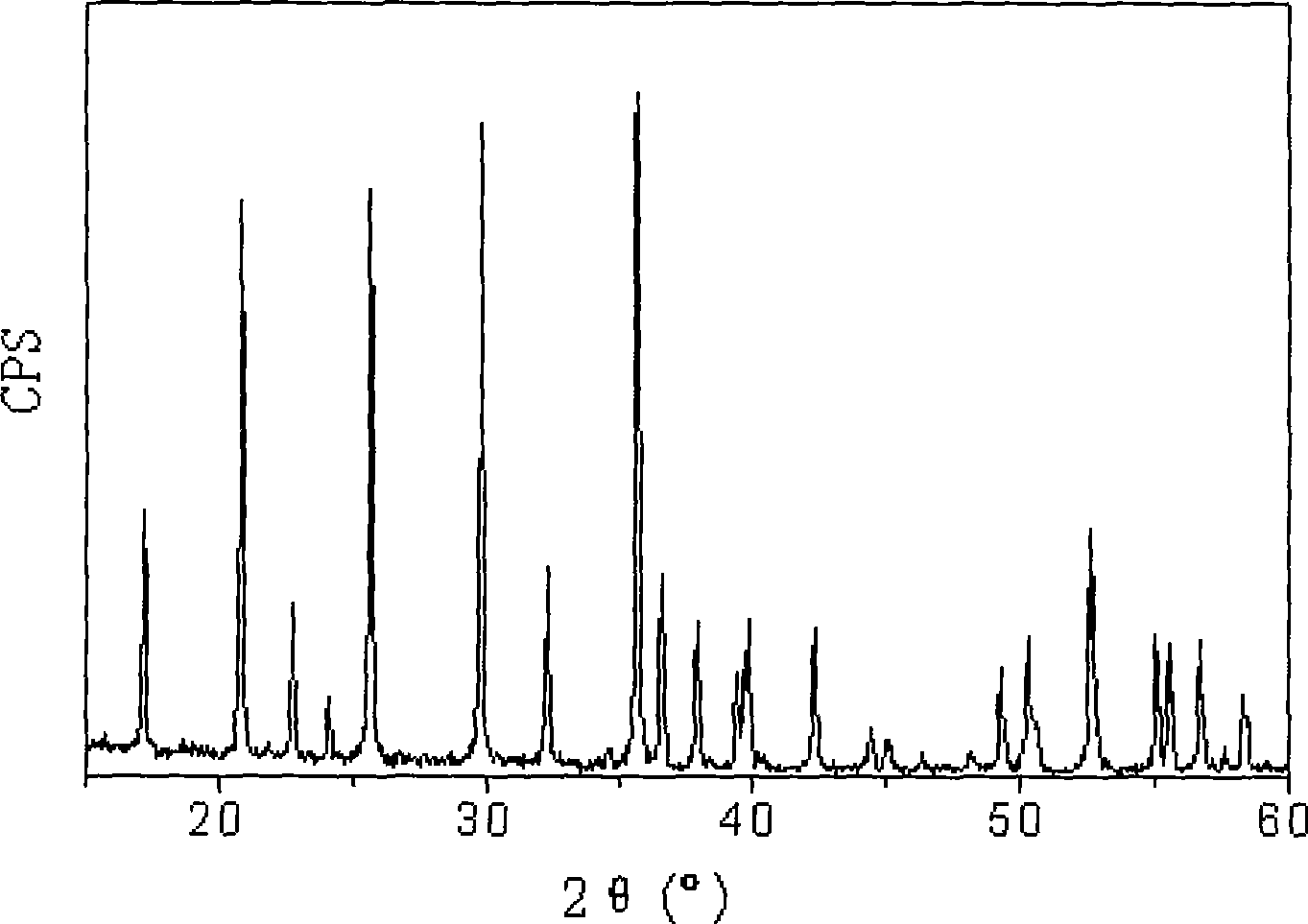

[0023] (6) Sintering the hydrated ferric phosphate at 500° C. for 10 h to obtain anhydrous ferric phosphate powder.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com