Preparation method of microcrystal mordenites

A mordenite and small-grain technology, which is applied in the field of synthesis of small-grain mordenite, can solve the problems of large amount of template agent, high production cost, high sodium content, etc., and achieve high activity and isomerization selectivity, wide silicon Effect of Al Ratio Variation Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

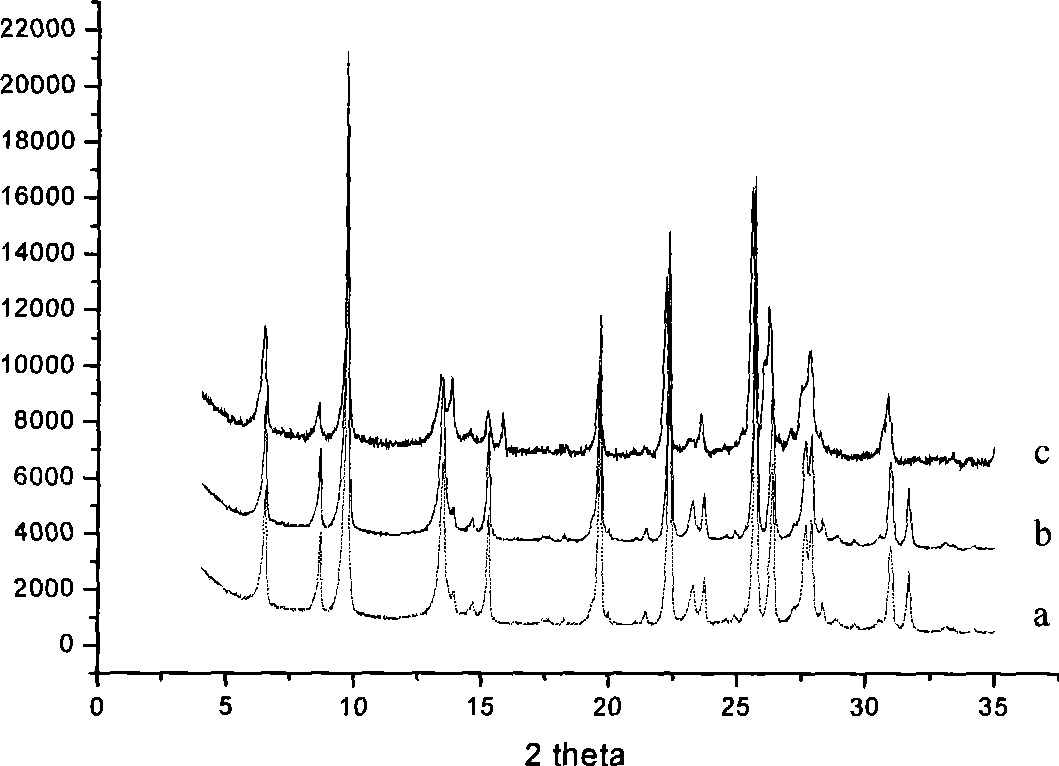

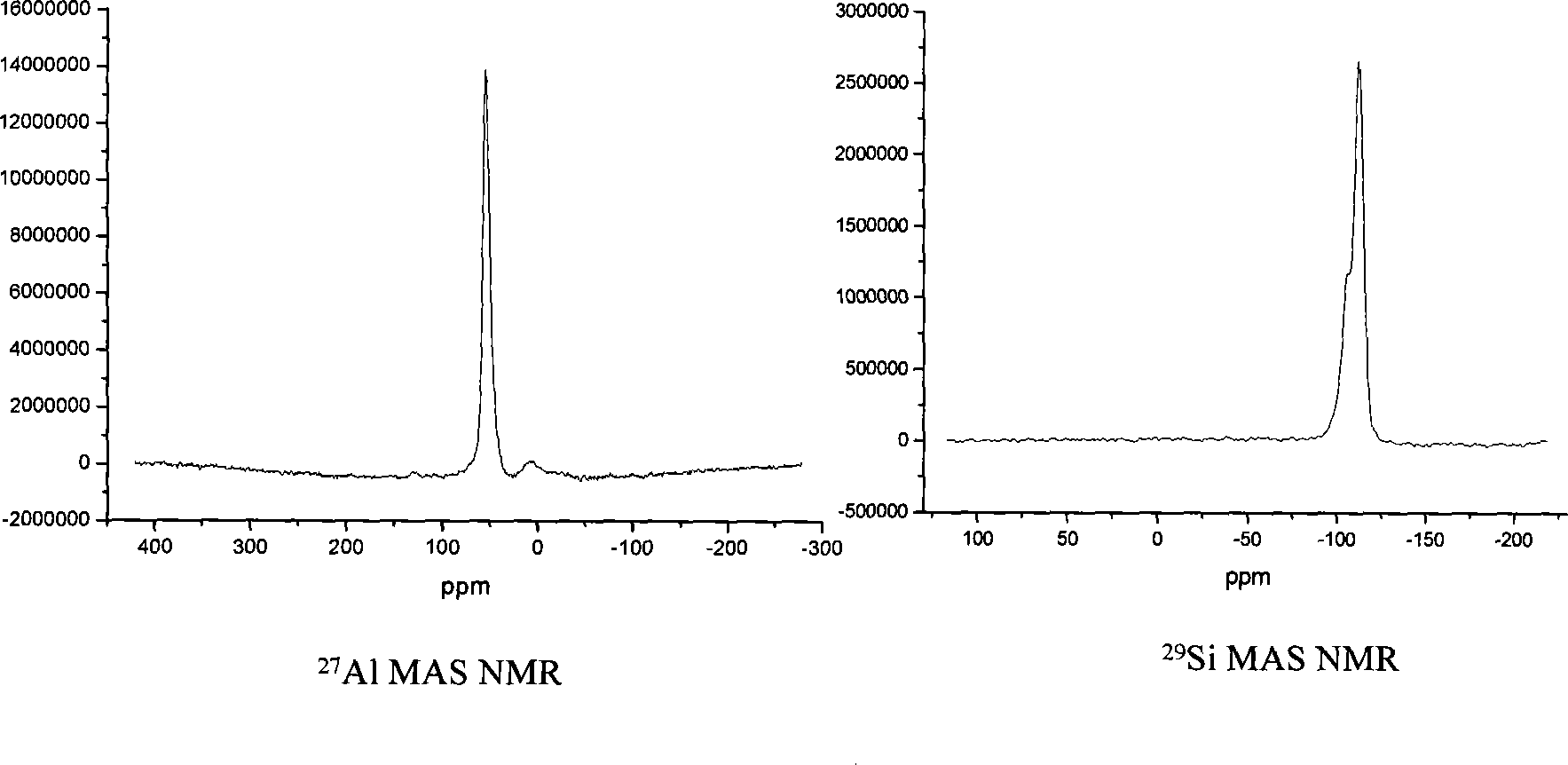

[0030] Add sodium metaaluminate solution containing 139.5 g / L of sodium oxide, 100.0 g / L of aluminum oxide, and tetraethylammonium hydroxide solution with a concentration of 2.03 mol / L (produced by Daxing Xingfu Fine Chemical Research Institute) into deionized water , stir evenly to make a mixed solution, add coarse-porous silica gel (7.8% by mass on ignition, produced by Qingdao Ocean Chemical Factory) with a particle size of 150 to 225 μm into the above mixed solution, so that the surface of the silica gel is wetted by the mixed solution to obtain a reaction The mixture, wherein the molar ratio of each raw material is shown in Table 1, and then the reaction mixture was aged in an autoclave at 60°C for 24 hours, crystallized at 120°C for 24 hours, crystallized at 148°C for 48 hours, and cooled to 25°C The solid product was isolated, washed with deionized water and dried at 80° C. for 12 hours to obtain the mordenite of the present invention. Its XRD was as follows: figure 1 A...

example 2

[0032] Add the sodium metaaluminate solution and tetraethylammonium hydroxide solution used in Example 1 into deionized water, stir evenly to make a mixed solution, and then add coarse-pored silica gel to the above mixed solution, so that the surface of the silica gel is wetted by the mixed solution , to obtain the reaction mixture, the mol ratio of each raw material is shown in Table 1. Transfer the reaction mixture to a high-pressure reactor for crystallization, crystallize at 70°C for 24 hours, crystallize at 135°C for 24 hours, separate the solid after cooling, wash with deionized water and dry at 80°C for 12 hours to obtain mordenite. Its properties are shown in Table 1.

example 3

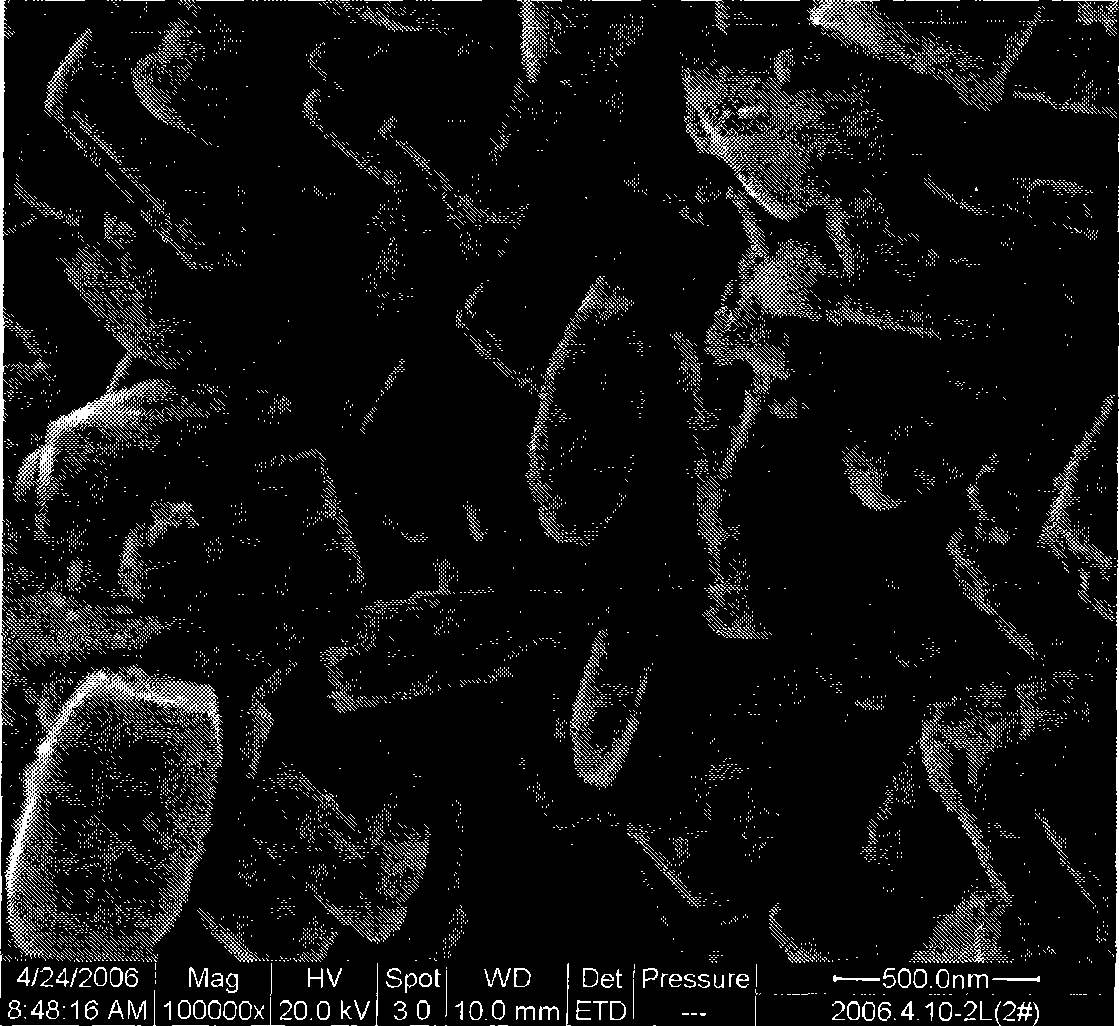

[0034] Add the sodium metaaluminate solution and tetraethylammonium hydroxide solution used in Example 1 into deionized water, stir evenly to make a mixed solution, and then add coarse-pored silica gel to the above mixed solution, so that the surface of the silica gel is wetted by the mixed solution , to obtain the reaction mixture, the mol ratio of each raw material is shown in Table 1. Transfer the reaction mixture into a high-pressure reactor, add mordenite with a silicon-aluminum ratio of 20, accounting for 5% of the total mass of the mixture on a dry basis, as a seed crystal, carry out two-stage crystallization at 120°C and 140°C, and separate the solid after cooling , the mordenite prepared by washing with deionized water and drying at 80°C for 12 hours, its properties are shown in Table 1, and the TEM photos are shown in Figure 4 . Figure 4 It shows that the mordenite synthesized by adding seeds is spherical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com