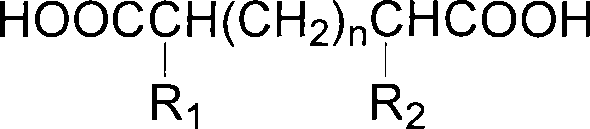

Electrolyte for aluminium electrolytic capacitor and preparation method of core solute thereof

An aluminum electrolytic capacitor and electrolyte technology, which is applied in electrolytic capacitors, capacitors, carboxylate/lactone preparation, etc., can solve the problems of low conductivity, large decrease in conductivity, and increase in capacitor impedance value, so as to achieve the life of the capacitor. Long, good thermal stability, good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

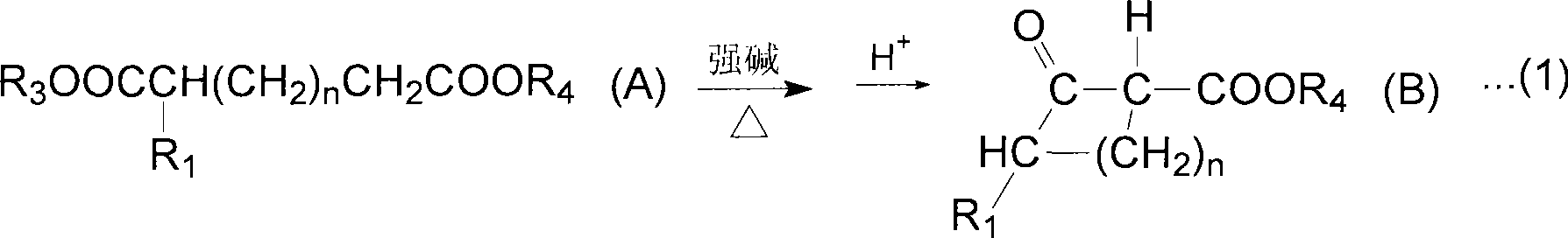

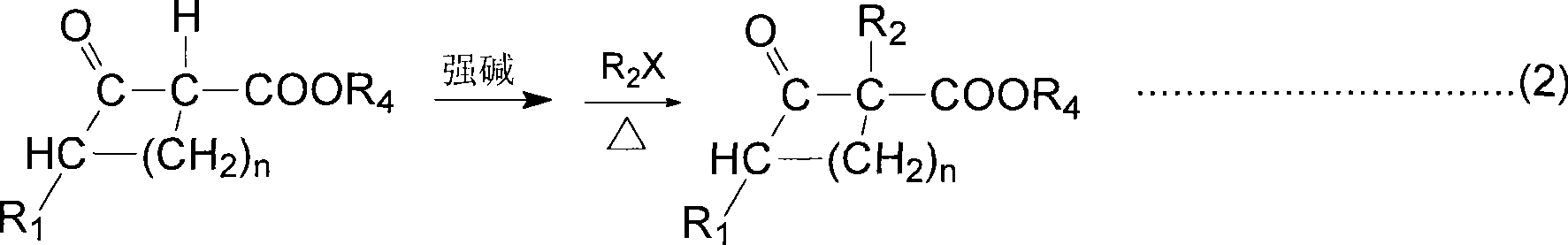

Method used

Image

Examples

Embodiment 1

[0049] Take 70g (0.4mol) of dimethyl adipate and put it into a 500ml three-necked flask, add 210g of diethylene glycol dimethyl ether, add 23g (0.43mol) of sodium methoxide under stirring, heat to 50°C and react under reduced pressure for 3 hours , after the reaction was complete, the solvent was distilled off. H 2 SO 4Neutralize to neutral, separate the oil layer, and the oil layer is subjected to vacuum distillation to separate 40g of the intermediate product B, put the intermediate product into a 500ml there-necked flask, add 15.2g of sodium methylate, add 140g of tert-butanol, under reflux (80 -85°C) was added dropwise into 49g of bromohexane, reacted for 24h, after the reaction was completed, distilled off tert-butanol, and used H 2 SO 4 Neutralize to neutral, separate the oil layer, distill under reduced pressure, carry out acid decomposition under heating with concentrated NaOH solution, H 2 SO 4 After neutralization, it was washed and dried to obtain 47 g of 2-hex...

Embodiment 2

[0051] Take 70g (0.4mol) of dimethyl adipate and put it into a 500ml three-necked flask, add 210g of diethylene glycol dimethyl ether, add 23g (0.43mol) of sodium methoxide under stirring, heat to 50°C and react under reduced pressure for 3h, After the reaction was completed, the solvent was distilled off, and the residue was washed with H 2 SO 4 Neutralize to neutral, separate the oil layer, and the oil layer is subjected to vacuum distillation to separate 41g of the intermediate product B, put the intermediate product into a 500ml three-necked flask, add 15.6g of sodium formate, add 140g of tert-butanol, under reflux (80~ 85°C) into 42g of bromobutane dropwise, and reacted for 24 hours. After the reaction was completed, tert-butanol was evaporated, and H 2 SO 4 Neutralized to neutral, separate oil layer. Vacuum distillation. Acid decomposition under heating with concentrated NaOH solution, H 2 SO 4 After neutralization, it was washed and dried to obtain 37 g of 2-butyl...

Embodiment 3

[0056] The acid obtained in Example 1 is made into ammonium salt and made into 250 g of 5% ethylene glycol solution, then 0.1% ammonium hypophosphite and 0.4% p-nitrobenzyl alcohol are added to make electrolyte, packed into a 500ml stainless steel bottle, sealed , Constant temperature at 105 ℃ and then test the parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com