Polyimide fiber and preparation method thereof

A polyimide fiber, polyimide technology, which is applied in the chemical characteristics of fibers, spinning solution preparation, dry spinning, etc., can solve the problems of easy sticking of filaments, large solvent residues, and high solvent toxicity. , to achieve the effect of accelerating the cyclization rate, shortening the reaction time, and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of partially cyclized polyamic acid fiber is prepared, and the steps are as follows:

[0023] (1) Synthesis of ternary copolymerization polyamic acid solution

[0024] Under nitrogen protection, in a three-necked flask, diamine (a mixture of p-phenylenediamine and 4,4'-diaminodiphenyl ether in a molar ratio of 2:8) was added to N,N'-dimethylacetamide (total solid content is 10%) in the solvent, stir quickly to make it dissolve, control the reaction temperature at 0 ° C, after the diamine is completely dissolved, add pyromellitic anhydride to the flask every half hour, and add it in four times, The molar ratio of pyromellitic anhydride to diamine is 1:1.02, and the wall of the bottle is washed several times with an appropriate amount of acetamide, and after 3 to 4 hours of copolymerization reaction, a light yellow viscous ternary copolymerized polyamic acid (PAA) is obtained solution.

[0025] (2) Preparation of partially cyclized polyamic acid

[0026] Accordi...

Embodiment 2

[0043] According to embodiment 1 technical scheme step (1) synthesis ternary copolymerization polyamic acid solution.

[0044]The solution of acetic anhydride, triethylamine and acetamide is mixed, wherein, the molar ratio of triethylamine and acetic anhydride is 1: 1, and acetamide 3ml, is prepared into partial cyclizing agent, press acetic anhydride: diamine molar ratio is 0.7:1, add part of the cyclizing agent and diamine to the polyamic acid solution, and react for 2 to 4 hours to obtain a golden yellow partially cyclized polyamic acid prepolymer.

[0045] Partially cyclized polyamic acid fibers are made by dry-wet spinning according to the technical solution step (3) of Example 1.

[0046] The obtained partially cyclized polyamic acid (PAA) fibers were loosely wound and subjected to microwave treatment under vacuum conditions for 3, 6, 10 and 15 minutes, respectively, and prepared polyimide by dehydration and cyclization treatment. fiber.

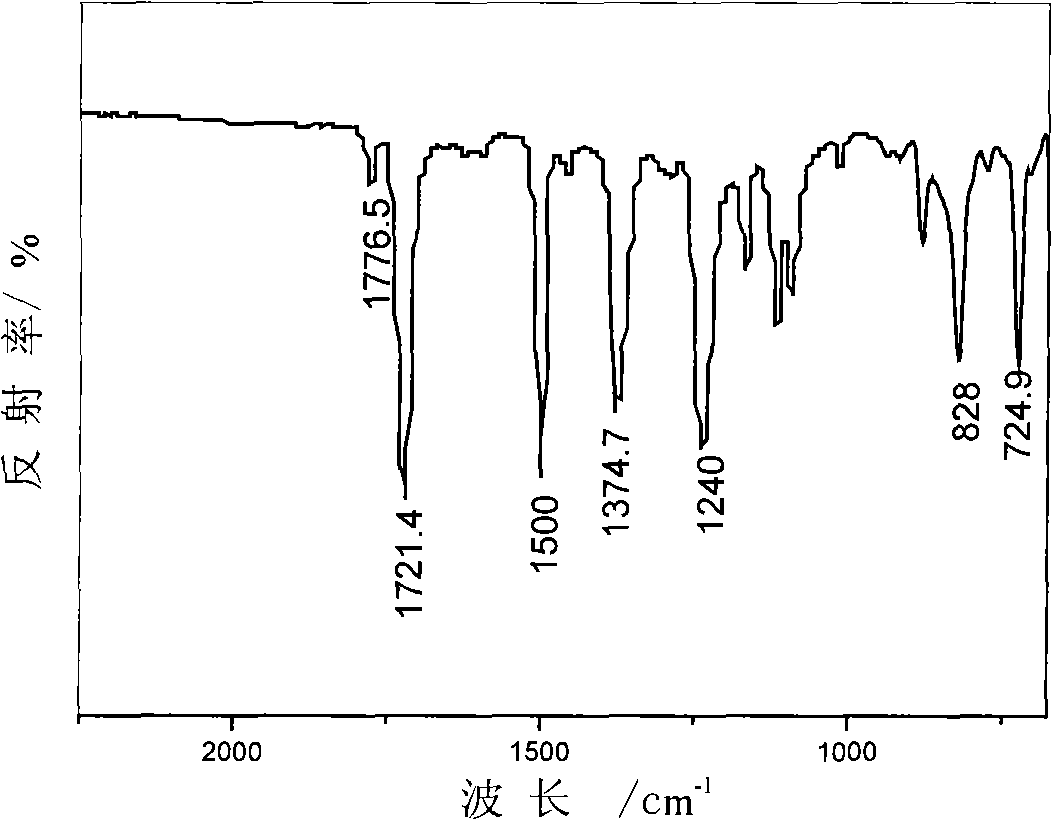

[0047] The polyimide fiber pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com