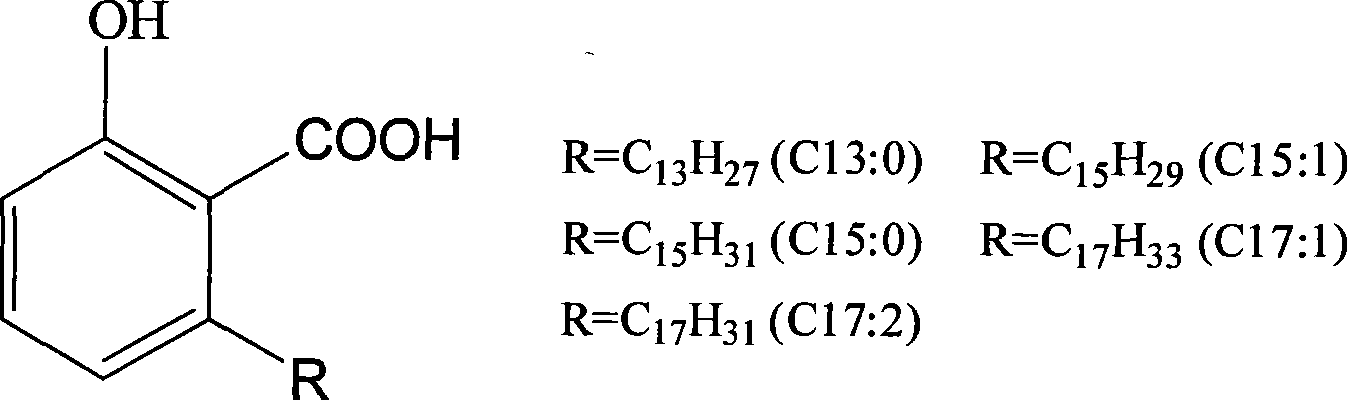

Ginkgoic acid preparation method using macroporous adsorption resin

A ginkgolic acid and pore adsorption technology, which is applied in the separation/purification of carboxylic acid compounds, antiviral agents, anti-infective drugs, etc., can solve the problems of large solvent consumption, poor solvent permeability, and high preparation cost, and achieve improved purity and quality, shorten preparation time, and reduce preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Ginkgo biloba extract material solution with a ginkgolic acid concentration of 3.2mg / ml, use HZ802 macroporous adsorption resin to absorb ginkgolic acid to saturation, first wash off the residual material solution that is not adsorbed by the resin with 2 times the volume of the resin, and then use 3 times the resin volume The 30% methanol aqueous solution of pH7.0 of volume washes away the impurity that is weaker than ginkgolic acid with HZ802 resin adsorption force, finally elutes the ginkgolic acid component with 45% methanol aqueous solution of pH11.2 of 3.5 times of resin volume, and eluent adjusts After the pH value reaches 6.5-7.0, the solvent is recovered under reduced pressure, concentrated in vacuo, separated from the upper layer oil, and dried to obtain the finished product of ginkgolic acid. After determination, the recovery rate of ginkgolic acid was 95.2%, and the purity of ginkgolic acid was 86.7%.

Embodiment 2

[0038] Ginkgo biloba extract extract containing 400ppm ginkgolic acid, under the condition of 65 ℃, with 6 times the volume of 95% ethanol aqueous solution with pH8. .1, after ethanol concentration 48% and ginkgolic acid concentration 0.16mg / ml, use AB-8 macroporous adsorption resin to adsorb ginkgolic acid to saturation, first wash off the residual material liquid that is not adsorbed by resin with water of 3.5 times of resin volume, and then Use the 35% ethanol aqueous solution of pH7.0 of 4.2 times of resin volume to wash away and the impurity weaker than ginkgolic acid with AB-8 resin adsorption force, finally use the 63% ethanol aqueous solution of pH9.0 of 5.1 times of resin volume to elute the ginkgolic acid group After the pH value of the eluent was adjusted to 7.0, the solvent was recovered under reduced pressure, concentrated in vacuo, the upper layer oil was separated, and dried into a finished product of ginkgolic acid. After determination, the recovery rate of gin...

Embodiment 3

[0040] Ginkgo biloba extract powder containing 2000ppm ginkgolic acid, under the condition of 60 ℃, with 3 times the volume of 60% methanol aqueous solution with pH9. 9. After the concentration of methanol is 54% and the concentration of ginkgolic acid is 0.48mg / ml, use HZ801 macroporous adsorption resin to absorb ginkgolic acid to saturation. The 40% methanol aqueous solution of pH 7.0 of the resin volume washes away the impurity with HZ801 resin adsorption force weaker than ginkgolic acid, finally elutes the ginkgolic acid component with 56% methanol aqueous solution of pH 10.1 of 4.8 times the resin volume, and the eluent After adjusting the pH value to 3.2, recover the solvent under reduced pressure, concentrate in vacuo, separate the oil in the upper layer, and dry it to obtain the finished product of ginkgolic acid. After determination, the recovery rate of ginkgolic acid was 96.1%, and the purity of ginkgolic acid was 85.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com