Preparation method for monodisperse composite nanoparticle

A composite nanoparticle and composite particle technology are applied in the field of preparation of monodisperse composite nanoparticles, which can solve the problems of increased process, increased production cost, long time consumption, etc., and achieves the effect of reducing process, saving cost and having good monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

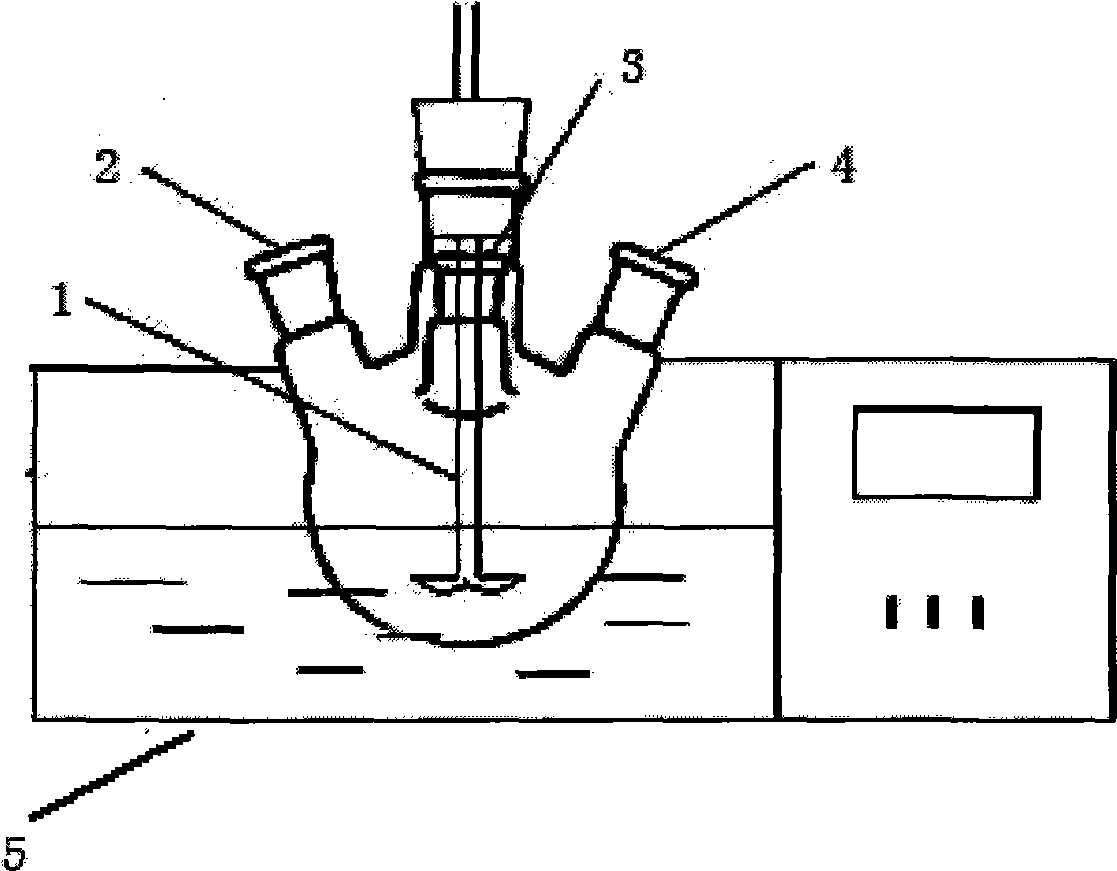

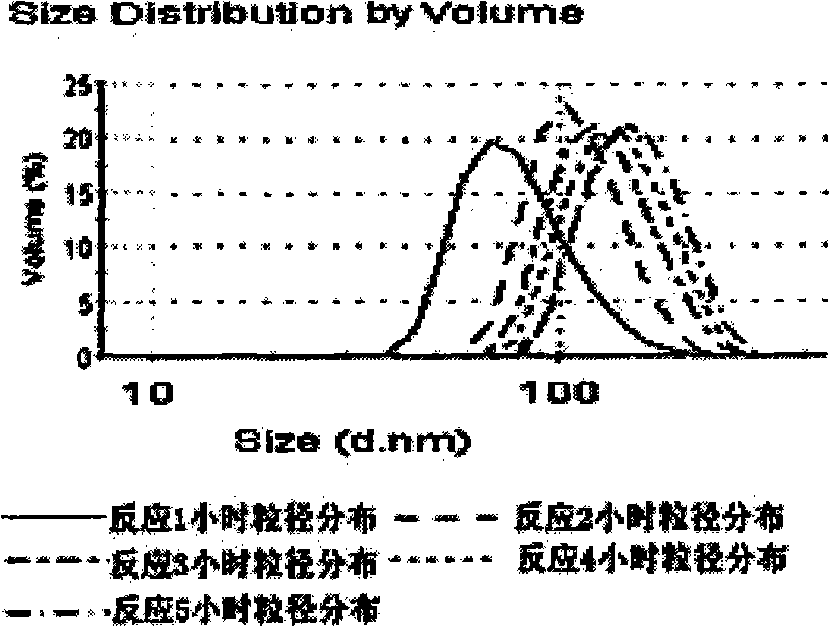

[0024] as attached figure 1 As shown, set the constant temperature water bath 5, keep the water temperature constant at 75°C, and put 20ml of SiO 2 (solid content 0.3g*ml -1 ), added to 350mL of deionized water, dispersed by ultrasonic vibration for 30min, and then poured into the reactor. Turn on stirrer 1, stir with 120rpm, feed N from nitrogen inlet 3 2 In 30 minutes, potassium persulfate was added from the feed port 4 as an initiator, and the molar concentration of the initiator system was 1.6*10 -3 mol*L -1 . Use advection pump to drop the monomer, and control the feeding time according to the required shell thickness, you can get SiO 2 Composite nanoparticles with organic core as the shell. 35nmSiO 2 Using methyl methacrylate (MMA) as the core to prepare silica / polymethyl methacrylate core-shell composite particles. The feed rate is 0.02, 0.04, 0.06ml*min respectively -1 , take a sample every hour, and measure its average particle size and polydispersity (PDI) v...

Embodiment 2

[0031] as attached figure 1 As shown, set the temperature of the constant temperature water bath at 75°C, and put 20ml of SiO 2 Sol (solid content 0.3g*ml -1 ), added to 350mL deionized water, dispersed by ultrasonic vibration for 20min, and then poured into the reactor. Turn on stirring at 120rpm, feed N 2 After 30 minutes, add potassium persulfate as an initiator, and the molar concentration of the initiator system is 1.6*10 -3 mol*L -1 . Use advection pump to drop the monomer, and control the feeding time according to the required shell thickness, you can get SiO 2 Composite nanoparticles with organic core as the shell. 35nm SiO 2 As the core, use vinyl acetate (VAC) as the monomer to prepare SiO 2 / PVAC (polyvinyl acetate) core-shell structure composite particles. The feed rate is 0.02, 0.04, 0.06ml*min respectively -1 , take a sample every hour, and measure its average particle size and polydispersity PDI value with a laser particle size analyzer. The experiment...

Embodiment 3

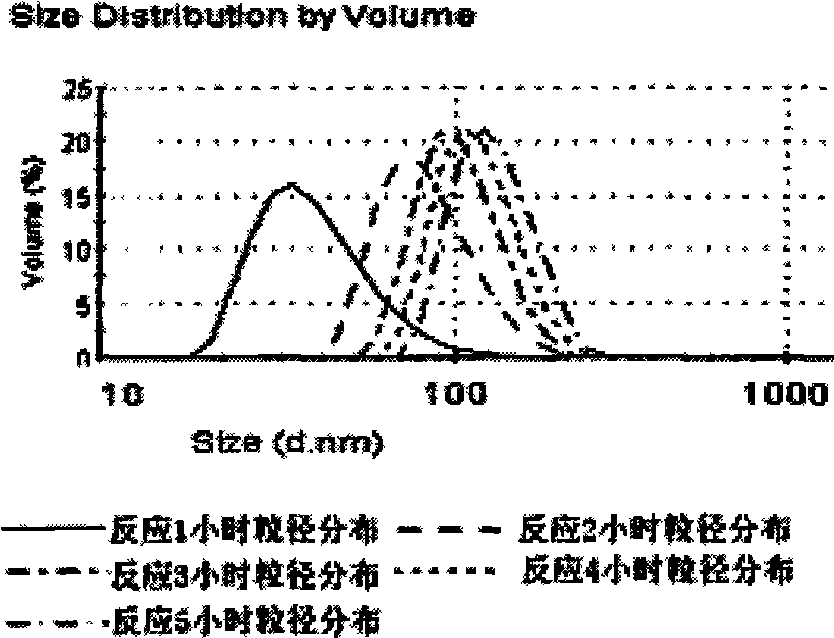

[0038] as attached figure 1 shown, with 230nmSiO 2 As the core, SiO was prepared using methyl methacrylate (MMA) as the monomer 2 / PMMA composite particles. Set the temperature of the constant temperature water bath at 75°C, and put 100ml of SiO 2 Sol (solid content 0.05g*ml -1 , particle size 230nm), was added to 200mL deionized water, ultrasonically vibrated and dispersed for 20min, then poured into the reactor. Turn on stirring at 120rpm, feed N from nitrogen inlet 3 2 In 30 minutes, potassium persulfate was added from the feed port 4 as an initiator, and the molar concentration of the initiator system was 1.6*10 -3 mol*L -1 . , use the parallel flow pump to drop the monomer MMA, the feed rate is 0.06ml*min -1 , take a sample every hour, and use a laser particle size analyzer to measure its average particle size and PDI value. The experimental results are shown in Table 3. Control the feed time according to the desired shell thickness, and get SiO 2 Composite na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com