Super-hydrophilic self-cleaning SiO2 antifogging coating and preparation method thereof

An anti-fog coating and self-cleaning technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of high energy consumption, many components, poor wear resistance and heat resistance of glass products, and achieve simple equipment and equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

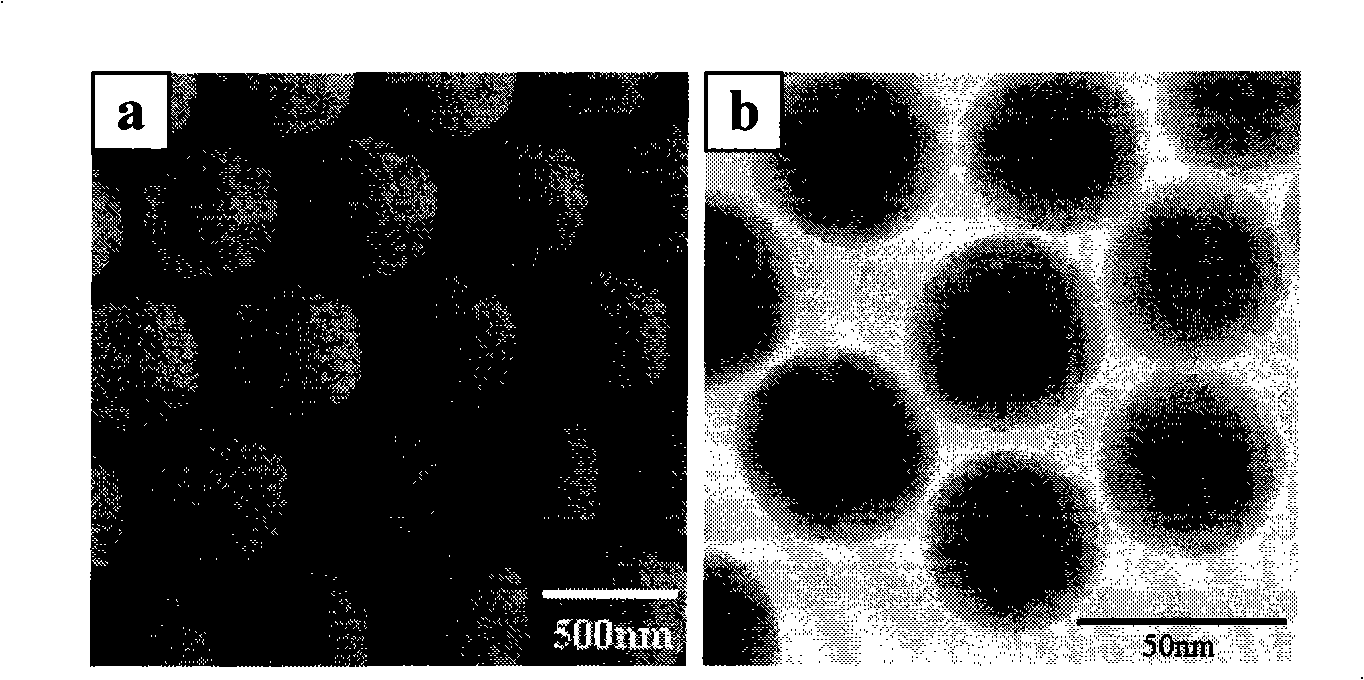

[0053] Preparation of PS spherical nanoparticles with a particle size of about 500 nm: Add 100 mL of distilled water, 13 mL of styrene monomer, and 0.1 g of polyvinylpyrrolidone into a 250 mL three-necked flask, and stir at room temperature for 15 minutes. Then dissolve 0.3g of initiator potassium persulfate in 20mL of distilled water, then pour it into the above-mentioned three-necked flask, pass through nitrogen for 30 minutes to remove the oxygen in the aqueous solution, then heat to 70°C and keep for 24 hours to obtain a particle size of about The white suspension of the PS spherical particle of 500nm, the scanning electron micrograph of the PS spherical particle of about 500nm particle diameter is as follows figure 1 as shown in a.

[0054] SiO with a particle size of about 50nm 2 Preparation of nanoparticles: Add 5mL of ammonia water and 100mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 10 minutes, then stir at 60°C for 2 minutes, add ...

Embodiment 2

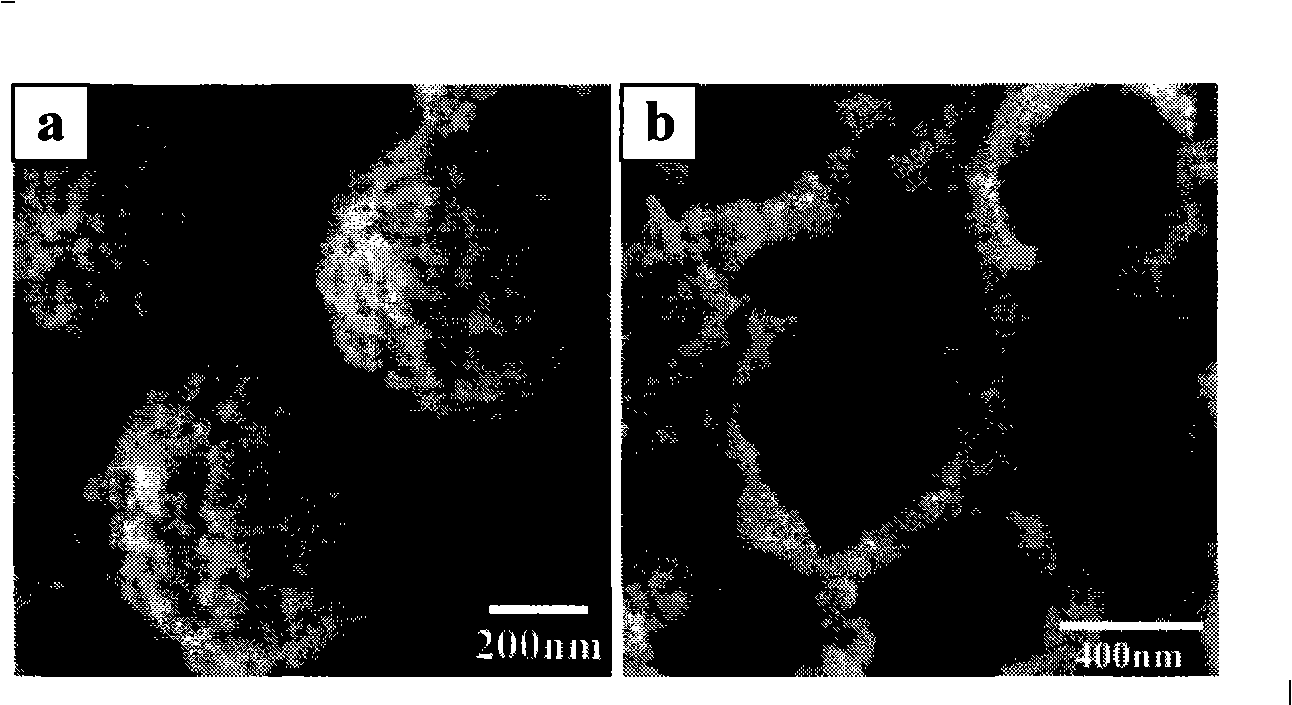

[0060] (PS / PDDA / PSS / PDDA / SiO obtained by embodiment 1 2 ) Ultrasonic dispersion of composite particles in distilled water to obtain a suspension with a mass fraction of 0.5% to 1.5%, and then adding this suspension to polydiallyldimethylammonium chloride with an excess volume concentration of 1 to 3 mg / mL In the aqueous solution, make the surface of the above product readsorb and electrostatically assemble a layer of polydiallyl dimethyl ammonium chloride, centrifuge, and ultrasonically wash the resulting solid product to remove the physically adsorbed polydiallyl dimethyl ammonium chloride , to obtain polydiallyldimethylammonium chloride coating, polystyrene sodium sulfonate coating, and polydiallyldimethylammonium chloride coating on the outside of polystyrene spherical nanoparticles. , solid SiO 2 Nanoparticle coating, polydiallyldimethylammonium chloride coating structure (PS / PDDA / PSS / PDDA / SiO 2 / PDDA), the composite particles are ultrasonically dispersed in distilled wa...

Embodiment 3

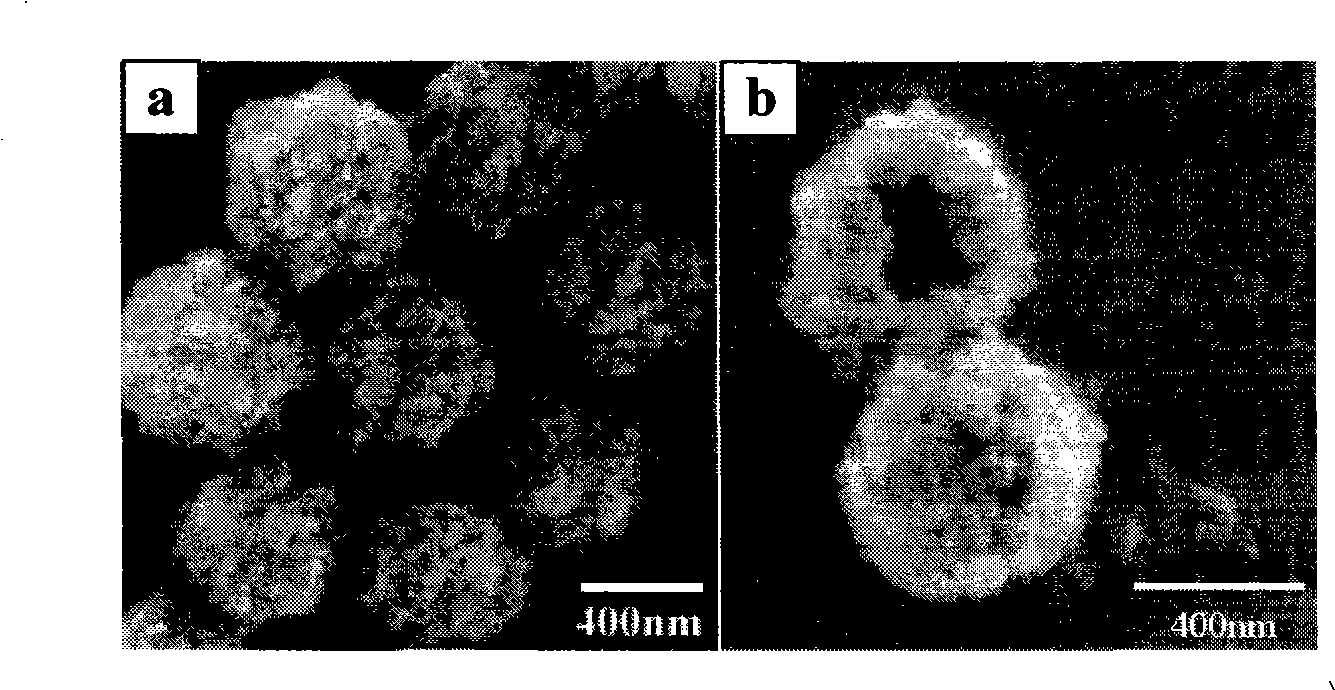

[0063] Preparation of super-hydrophilic anti-fog coating: use 98% H 2 SO 4 with a mass concentration of 30% H 2 o 2 The ordinary glass sheet is treated with the mixed solution with a volume ratio of 7:3, the treated glass sheet is washed with distilled water, dried with nitrogen, and the treated substrate is immersed in a PDDA solution with a concentration of 1-3mg / mL Take it out after 5 minutes, and deposit polydiallyldimethylammonium chloride coating on the glass surface, wash with distilled water to remove physically adsorbed PDDA, blow dry with nitrogen, and then immerse in a concentration of 1-3mg / mL Sodium polystyrene sulfonate (PSS) solution for 5 minutes, take it out, wash with distilled water, blow dry with nitrogen, and deposit a coating of sodium polystyrene sulfonate on the coating of polydiallyldimethylammonium chloride , and then continue to cross-repeat the above-mentioned process steps of depositing polydiallyl dimethyl ammonium chloride and depositing sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com