Spontaneous hydro-thermal method for preparing special composite nano ceramic powder for ceramic tooth

A technology of nano-ceramic powder and hydrothermal method, which is applied in the direction of dentures, etc., can solve problems such as agglomeration, environmental pollution, and large particle size, and achieve the effects of low cost, good sintering activity, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

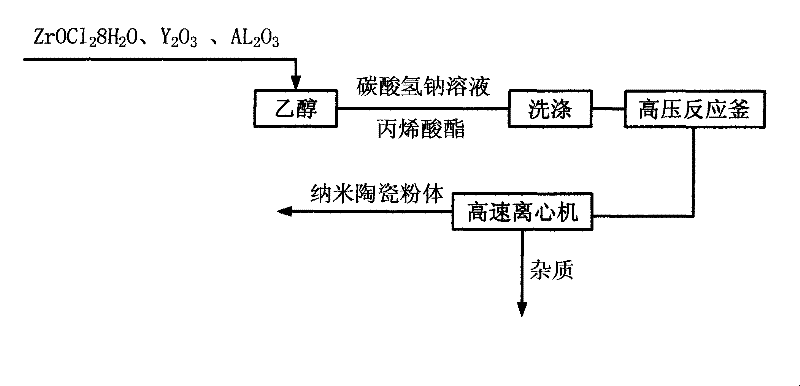

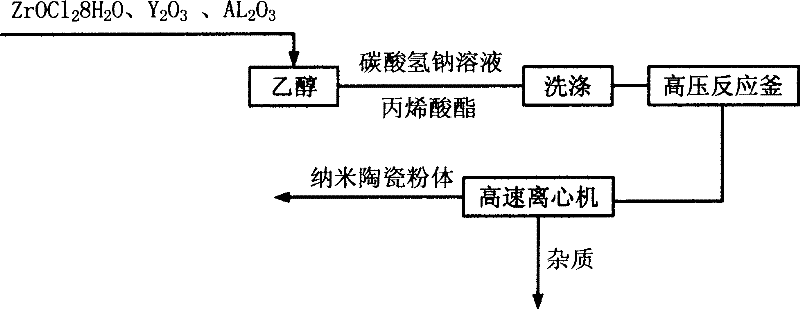

Method used

Image

Examples

Embodiment 1

[0025] ZrOCl with a total weight of 35 g 2 ·8H 2 O, Y 2 O 3 and AL 2 O 3 According to the molar ratio of 94:5:1, dissolve in 100ml of ethanol, add 200ml of sodium bicarbonate solution with a mass percentage of 5%, add 0.175g of dispersant A15, that is, acrylate, then wash with ultrasonic washing equipment for 25 minutes, send Into the autoclave, hydrothermally reacted for 8 hours under the conditions of 4MPa and 220°C; the sediment was sent to the high-speed centrifuge washing equipment through the pipeline, washed at 16,000 rpm for 10 minutes, repeated 3 times, to remove the sodium chloride ions and residual impurities to obtain pure tetragonal composite nano-ceramic powder with high crystallinity.

[0026] The particle size of the nano-ceramic powder obtained in this example is between 20 and 30 nm.

Embodiment 2

[0028] ZrOCl with a total weight of 70 g 2 ·8H 2 O, Y 2 O 3 and AL 2 O 3 Dissolve in 200ml of ethanol at a molar ratio of 93:4:3, add 400ml of sodium bicarbonate with a concentration of 6% by mass, mix well, add 0.35g of dispersant A15 (acrylate), and then wash with ultrasonic washing equipment for 25 minutes , sent into the autoclave, hydrothermally reacted under the conditions of 5Mpa and 230 ° C for 9 hours; the sediment was sent to the high-speed centrifuge washing equipment through the pipeline for repeated filtration 3 times, and the sodium chloride ions and residual impurities were removed to obtain Pure tetragonal composite nano-ceramic powder with high crystallinity.

[0029] The particle size of the nano-ceramic powder obtained in this example is between 20 and 30 nm.

Embodiment 3

[0031] ZrOCl with a total weight of 350 g 2 ·8H 2 O, Y 2 O 3 and AL 2 O 3 Dissolve in 1000ml deionized water at a molar ratio of 89:8:3, add 2000ml of potassium bicarbonate with a concentration of 7% by mass, and mix well, add 1.75g of dispersant A15 (acrylate), and then wash 25 minutes, sent into the autoclave, hydrothermally reacted under the conditions of 6Mpa and 240 ° C for 10 hours; the sediment was sent to the high-speed centrifuge washing equipment through the pipeline for repeated filtration 3 times, and the potassium chloride ions and residual impurities were removed, namely A pure tetragonal composite nano-ceramic powder with high crystallinity is obtained.

[0032] The particle size of the nano-ceramic powder obtained in this example is between 20 and 30 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com