Method for producing microbial compound bacterial fertilizer

A technology of microbial compound bacteria and production method, which is applied in the field of agricultural microbial compound bacteria fertilizer, can solve the problems of unfavorable popularization, insignificant effect, unattainable indicators, etc., and achieves the effects of low price, improved agricultural ecological environment, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment one: get the activated sludge 100kg that lotus monosodium glutamate plant treatment sewage produces, add the molasses 18kg that is provided by Beijing Haichang Xinlin Science and Technology Development Co., Ltd., and add the water of 20kg, insert compound microorganism bacterium liquid 6kg (in the bacterium liquid Containing Paenibacillus macerans, Bacillus megaterium, Bacillus cereus, Bacillus colioids, actinomycetes, yeast and lactic acid bacteria, the mass ratio is 30:10:5:25:10:5:15), mixed Evenly add peat 15kg after cultivating at 30°C for 30h, then add 1.3kg of trace elements (containing borax, zinc chloride, ammonium molybdate, manganese sulfate, ferrous sulfate, copper sulfate in the trace elements, and its mass ratio is 15: 10:2:5:6:4), then granulated, and dried at 35°C to obtain sludge compound bacterial fertilizer.

Embodiment 2

[0049] Embodiment two: get the activated sludge 200kg that Yanjing brewery sewage treatment produces, add the molasses 30kg that is provided by Beijing Haichang Xinlin Science and Technology Development Co., Ltd., and add the water of 50kg, insert compound microbial bacterial liquid 8kg (bacterial liquid Contains Paenibacillus macerans, Bacillus megaterium, Bacillus cereus, Bacillus colioids, actinomycetes, yeast and lactic acid bacteria, the mass ratio is 35:5:15:15:5:15:5), Mix evenly and add peat 40kg after cultivating at 35°C for 40h, then add 3kg of trace elements (containing borax, zinc chloride, ammonium molybdate, manganese sulfate, ferrous sulfate, copper sulfate in the trace elements, and its mass ratio is 20: 10:3:5:4:5), then granulated, and dried at 40°C to obtain sludge compound bacterial fertilizer.

Embodiment 3

[0050] Embodiment three: get the activated sludge 500kg that lotus monosodium glutamate plant treatment sewage produces, add the molasses 45kg that is provided by Beijing Haichang Xinlin Science and Technology Development Co., Ltd., and add the water of 150kg, insert compound microorganism bacterium liquid 20kg (in the bacterium liquid Containing Paenibacillus macerans, Bacillus megaterium, Bacillus cereus, Bacillus colioids, actinomycetes, yeast and lactic acid bacteria, the mass ratio is 25:15:10:20:15:10:5), mixed Add 70kg of peat evenly after cultivating at 40°C for 50h, and then add 10kg of trace elements (the trace elements contain borax, zinc chloride, ammonium molybdate, manganese sulfate, ferrous sulfate, copper sulfate, and the mass ratio is 25:10 : 4: 5: 6: 5), then granulated, and dried at 50°C to obtain sludge compound bacterial fertilizer.

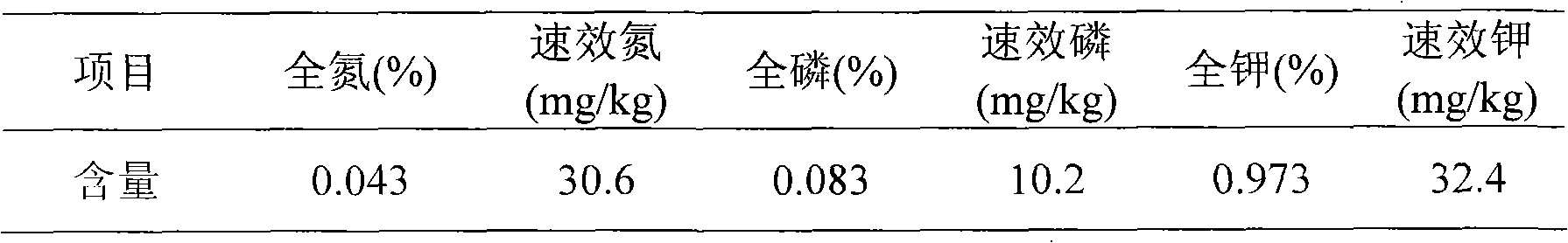

[0051] The nutrient situation of the soil used in the table 1 test

[0052]

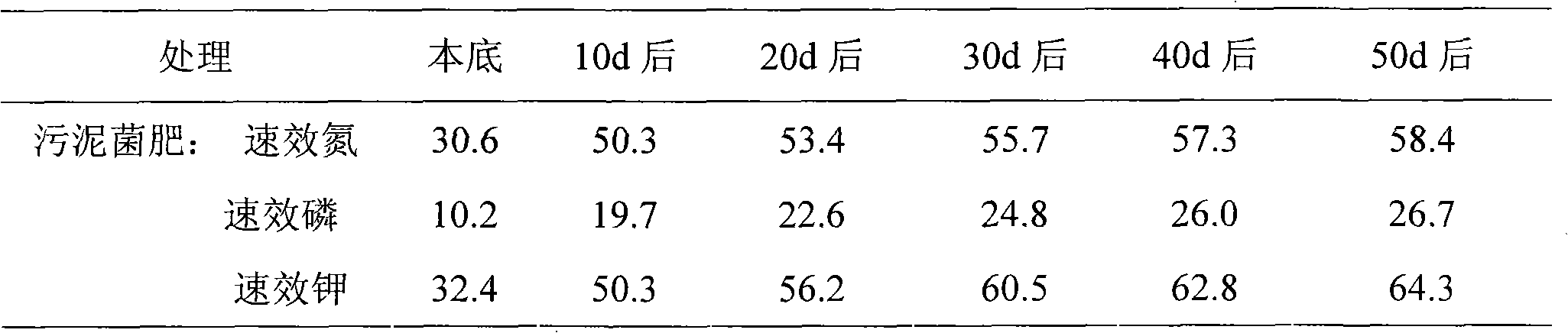

[0053] Table 2 Fertility control (unit: m...

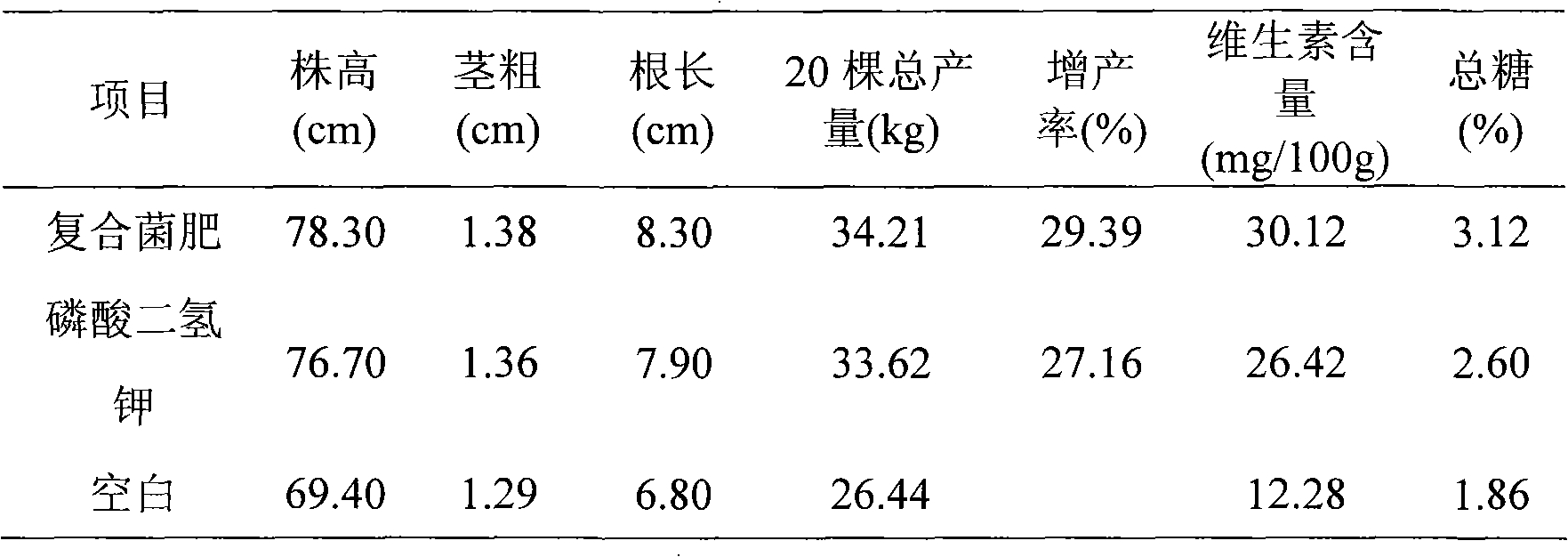

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com