Method for separating and recovering vanadium and chrome from vanadium and chrome-containing waste

A technology for separation and recovery of vanadium and chromium, applied in the direction of improving process efficiency, etc., can solve the problems of no practical significance, difficult control and operation, and difficult leaching of vanadium and chromium, and achieve good control, low production cost, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

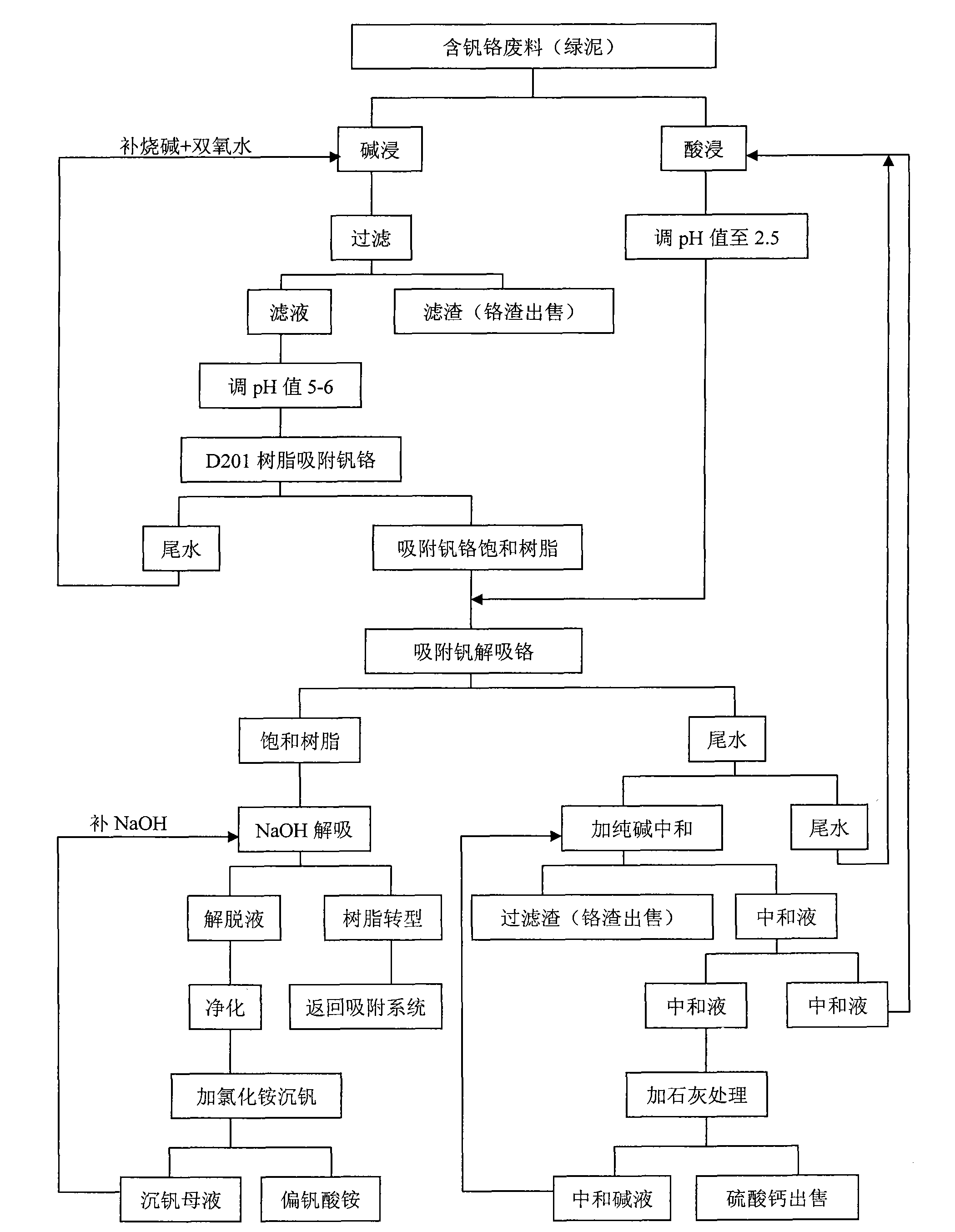

Image

Examples

Embodiment 1

[0029] 1. Alkali leaching and ion exchange of alkaline leaching solution: add 10 kg of vanadium-chromium-containing waste (green mud) containing 6.237% by mass of vanadium and 21.39% of chromium, add water according to the solid-liquid ratio of 1:5, and then add 6% by volume of water Sodium hydroxide and 4‰ hydrogen peroxide are leached with mechanical stirring at room temperature, and 4‰ hydrogen peroxide is added once after 1 hour, and 4‰ hydrogen peroxide is added once after 1 hour, stirred and leached for 8 hours, and filtered to obtain The vanadium grade in the alkali immersion solution is 11.23g / L, and the chromium grade is 20.34g / L (the filter residue analysis shows that the vanadium grade is lower than 0.2wt% and is sold as chromium residue, and if it is higher than 0.3wt%, it is returned to alkali dissolution), and the pH value is adjusted with industrial sulfuric acid To 5, the D201 resin flowing through transformation treatment absorbs vanadium and chromium. The tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com