Method for preparing FePt:RE amorphous alloy nano material mixed with rare earth elements

A rare earth element and nano-alloy technology, applied in the field of materials, can solve the problems of uneven doping, strict technical requirements, large particle size, etc., and achieve the effects of good monodispersity, uniform particle size, and inhibiting phase transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of FePt:Eu alloy magnetic nanoparticles

[0029] In the first step, 0.031mmol H 2 PtCl 6 ·6H 2 O with 0.031mmol Fe 2 (C 2 o 4 ) 3 ·5H 2 O and 0.007mmolEu(NO 3 ) 3 Completely dissolve in 2ml of absolute ethanol, then add 0.2g of sodium oleate and 0.011mol of DB24C8 in sequence, and stir with ultrasonic vibration for 10 minutes until the solid is completely dissolved.

[0030] In the second step, add a mixed solution of 4ml 1,2-propanediol and 2ml oleic acid, then transfer the whole mixed system to the autoclave, raise the temperature to 423K at a rate of 2°C / min, and heat it in a muffle furnace at 423K Under the condition of insulation for 15 hours, after the reaction was completed, it was cooled to room temperature.

[0031] In the third step, the particles deposited at the bottom of the reactor were washed several times with absolute ethanol and distilled water successively, and centrifuged at a speed of 5000 rpm for 10 minutes, ...

Embodiment 2

[0033] Embodiment 2: the preparation of FePt:Dy alloy magnetic nanoparticles

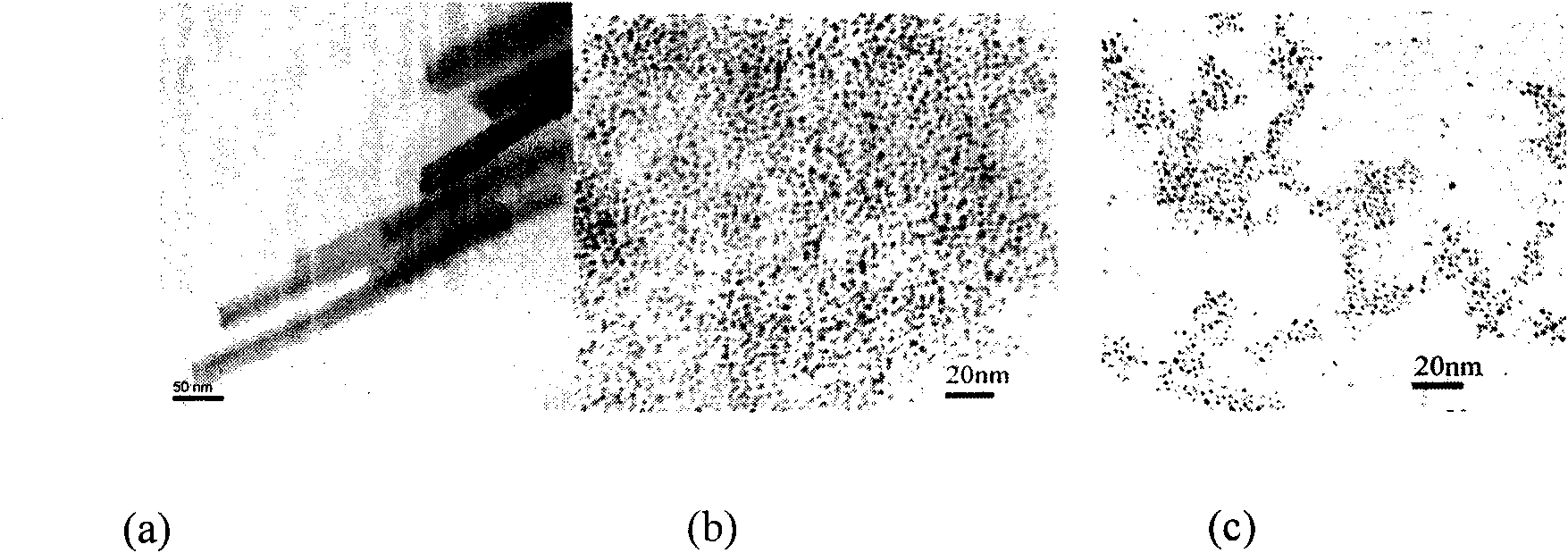

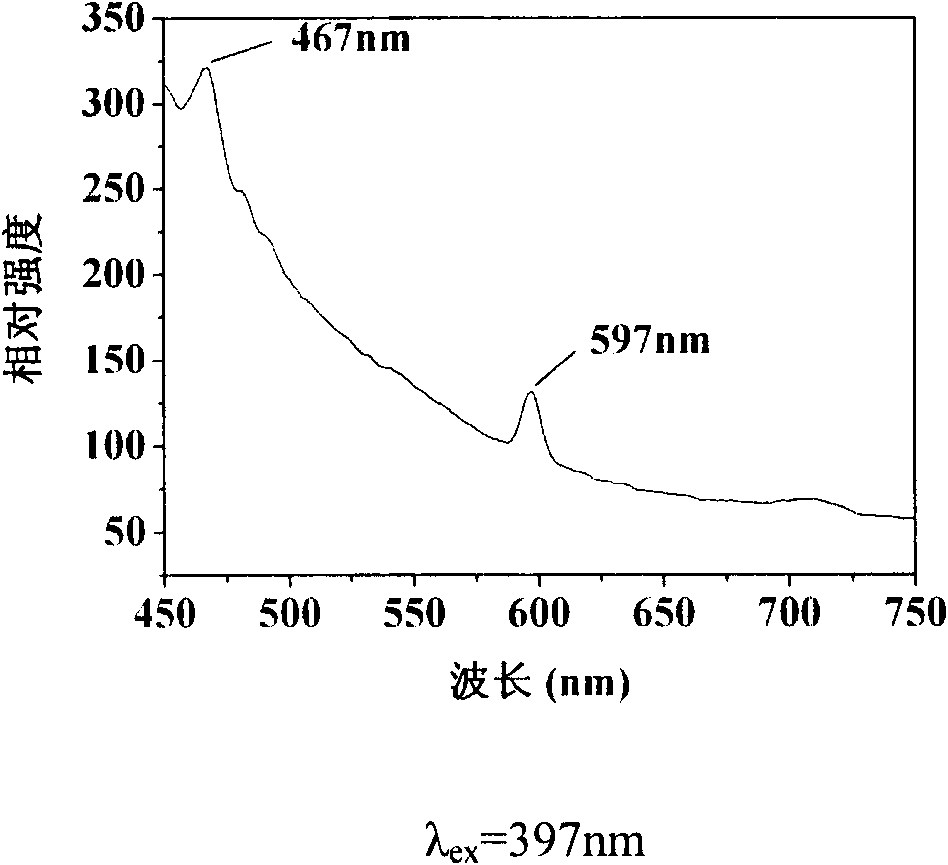

[0034] 0.031mmol H 2 PtCl 6 ·6H 2 O with 0.031mmol Fe 2 (C 2 o 4 ) 3 ·5H 2 O and 0.007mmol Dy(NO 3 ) 3Completely dissolve in 2ml of absolute ethanol, then add 0.2g of sodium oleate and 0.011mol of DB24C8 in sequence, and stir with ultrasonic vibration for 10 minutes until the solid is completely dissolved. Add a mixed solution of 4ml 1,2-propanediol and 2ml oleic acid, then transfer the whole mixed system to an autoclave, react in a muffle furnace at 423K for 15 hours, and cool to room temperature after the reaction. The rest are operated according to the steps described in Example 1. figure 1 The TEM photomicrograph in (b) shows that the product is an amorphous nanoscale particle with a small particle size and monodispersity. figure 2 When excited at 397nm, two emission peaks at 467nm and 597nm appear on the emission spectrum of FePt:Dy, which correspond to Dy 3+ 4F 9 / 2 -6H 15 / 2 with...

Embodiment 3

[0035] Embodiment 3: the preparation of FePt: Ce alloy magnetic nanoparticles

[0036] 0.031mmol H 2 PtCl 6 ·6H 2 O with 0.031mmol Fe 2 (C 2 o 4 ) 3 ·5H 2 O and 0.007mmol Ce(NO 3 ) 3 Completely dissolve in 2ml of absolute ethanol, then add 0.2g of sodium oleate and 0.011mol of DB24C8 successively, and react according to the steps described in Example 2. figure 1 The TEM photomicrograph in (c) shows that the product is an amorphous nanoscale particle with a small particle size and monodispersity.

[0037] The magnetic performance characterization data of the product obtained in Table 1 embodiment 1, example 2, example 3

[0038] Alloy nanoparticles

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com