Composite material with high conductivity intercalation structure and preparation method thereof

A technology of high conductivity and composite materials, applied in the field of functional materials, can solve problems such as unfavorable dispersion effect and improved conductivity, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

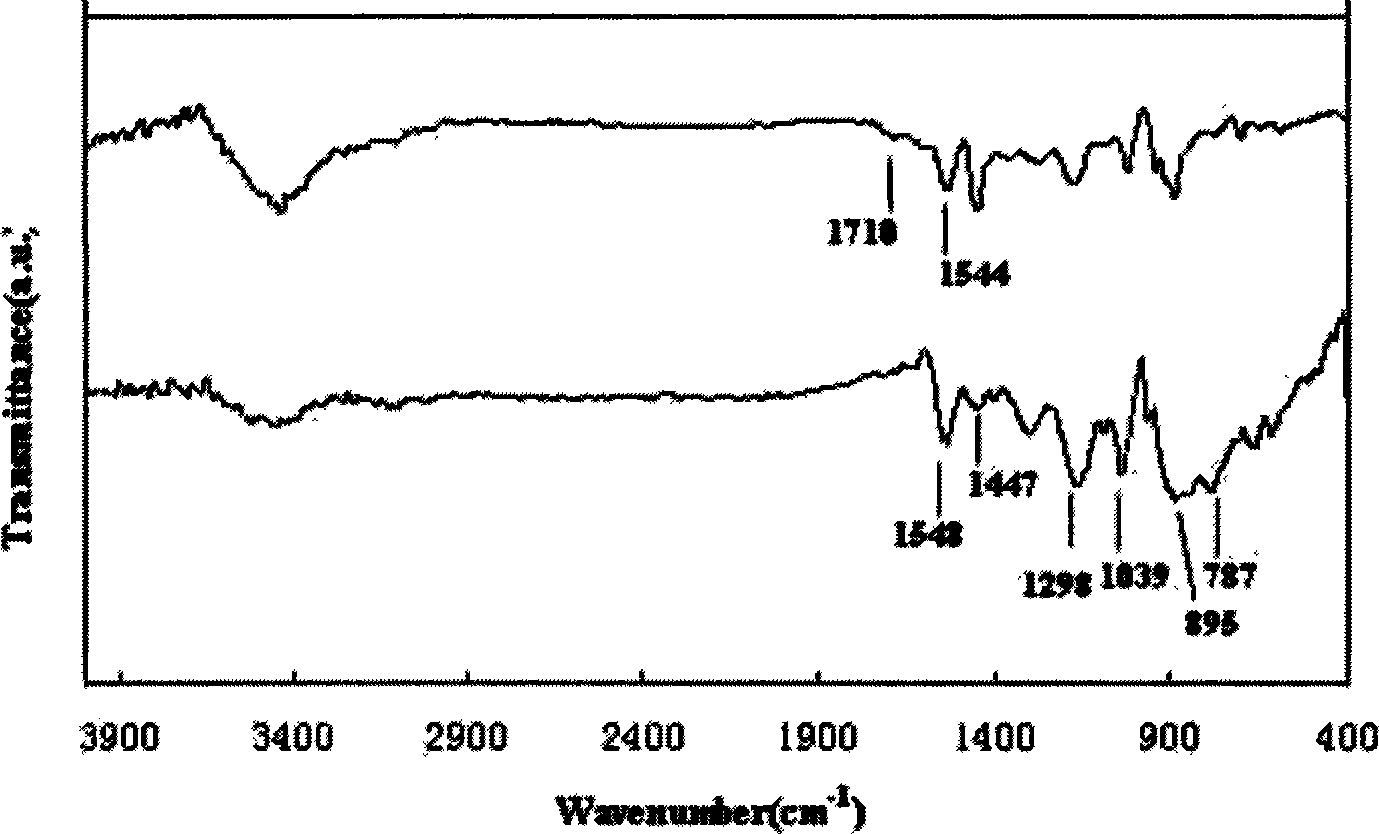

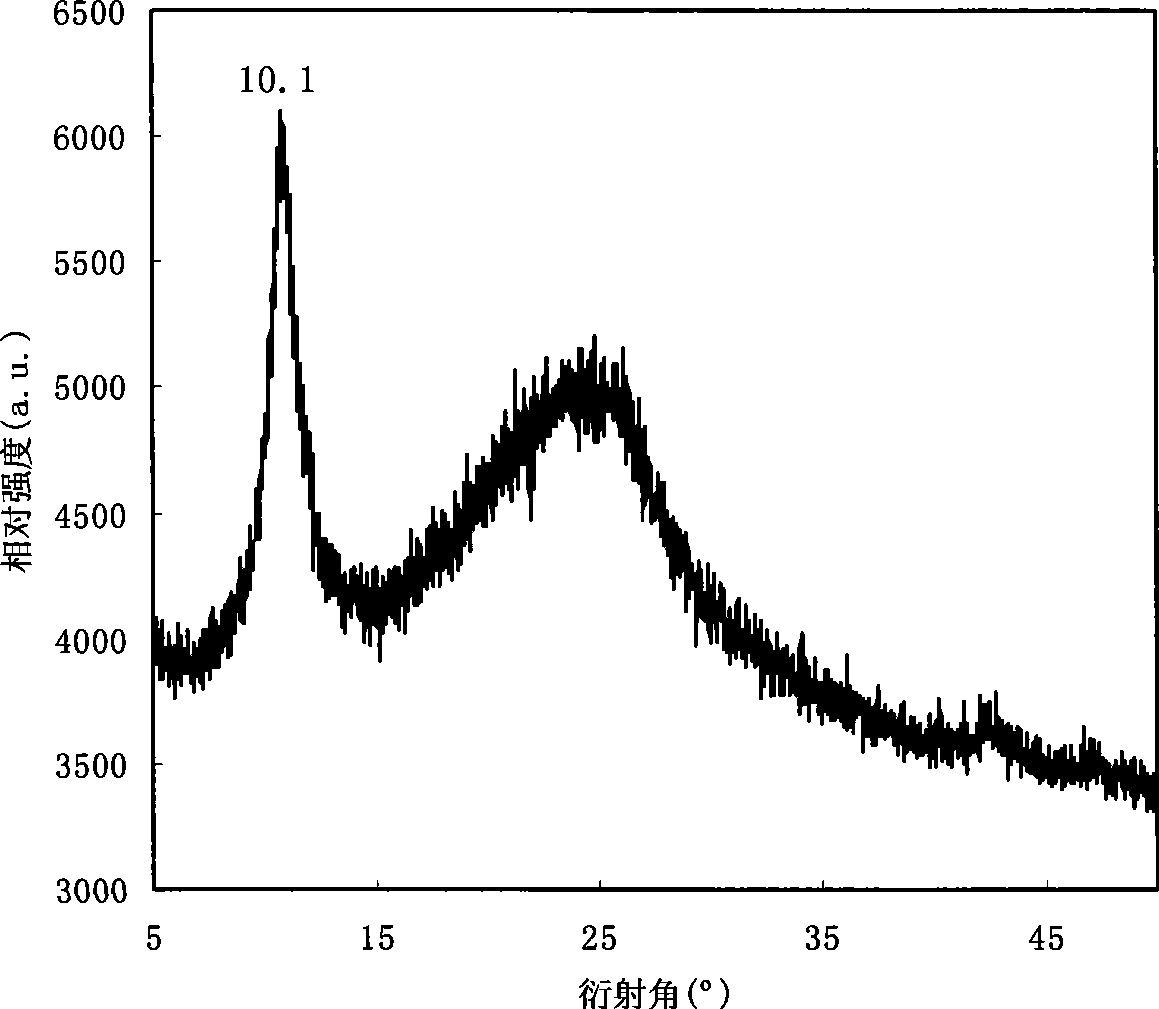

[0023] The polypyrrole / graphite oxide composite material with a high conductivity intercalation structure adopts the emulsion polymerization method, and the specific steps are as follows:

[0024] (1) 1mg·ml in 70ml graphite oxide aqueous solution -1 Add hydrochloric acid to adjust pH=1, add surfactant cetyltrimethylammonium bromide 70mg, treat under ultrasonic wave for 30min, form colloidal dispersion liquid.

[0025] (2) Add 0.07 g of pyrrole monomer to the colloidal dispersion in step (1), add dropwise oxidant ammonium persulfate aqueous solution 0.24 g / 5 ml under magnetic stirring, and perform emulsion polymerization at 0-5° C. for 10 h.

[0026] (3) Filter the black liquid obtained in step (2), wash with acetone and deionized water, and dry at 80° C. for 12 hours to obtain a polypyrrole / graphite oxide composite with high conductivity in an intercalation structure.

[0027] Using the four-probe method, the electrical conductivity of the polypyrrole / graphite oxide composit...

Embodiment 2

[0030] The polypyrrole / graphite oxide composite material with a high conductivity intercalation structure adopts the emulsion polymerization method, and the specific steps are as follows:

[0031] (1) 1mg·ml in 70ml graphite oxide aqueous solution -1 Add hydrochloric acid to adjust pH = 3, add emulsifier cetyltrimethylammonium bromide 350mg, treat under ultrasonic wave for 60min, and change to magnetic stirring after the system is fully dissolved.

[0032] (2) Add 0.35g of pyrrole monomer to the solution in step (1), control the reaction temperature at 0-5°C, and under the action of magnetic stirring, add 1.19g / 5ml of oxidant ammonium persulfate aqueous solution dropwise to start the reaction and continue Reaction 10h.

[0033] (3) Filter the black liquid obtained in step (2), wash with acetone and deionized water, and dry at 80° C. for 12 hours to obtain a highly conductive polypyrrole / graphite oxide composite with an intercalation structure.

[0034] A polypyrrole / graphite...

Embodiment 3

[0036] The polypyrrole / graphite oxide composite material with a high conductivity intercalation structure adopts the emulsion polymerization method, and the specific steps are as follows:

[0037](1) 70ml graphite oxide aqueous solution 2mg·ml -1 Add hydrochloric acid to adjust pH=1, add emulsifier cetyltrimethylammonium bromide 140mg, treat under ultrasonic wave for 30min, and change to magnetic stirring after the system is fully dissolved.

[0038] (2) Add 0.14g of pyrrole monomer to the solution in step (1), control the reaction temperature at 0-5°C, and under the action of magnetic stirring, add 0.48g / 5ml of oxidant ammonium persulfate aqueous solution dropwise to start the reaction and continue Reaction 10h.

[0039] (3) Filter the black liquid obtained in step (2), wash with acetone and deionized water, and dry at 80° C. for 12 hours to obtain a highly conductive polypyrrole / graphite oxide composite with an intercalation structure.

[0040] A polypyrrole / graphite oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com