Coal-based clean energy-saving methane technology

A process and methane technology, applied in the field of carbon oxide synthesis of methane, can solve the problems of energy loss, complex process, high cost, and achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

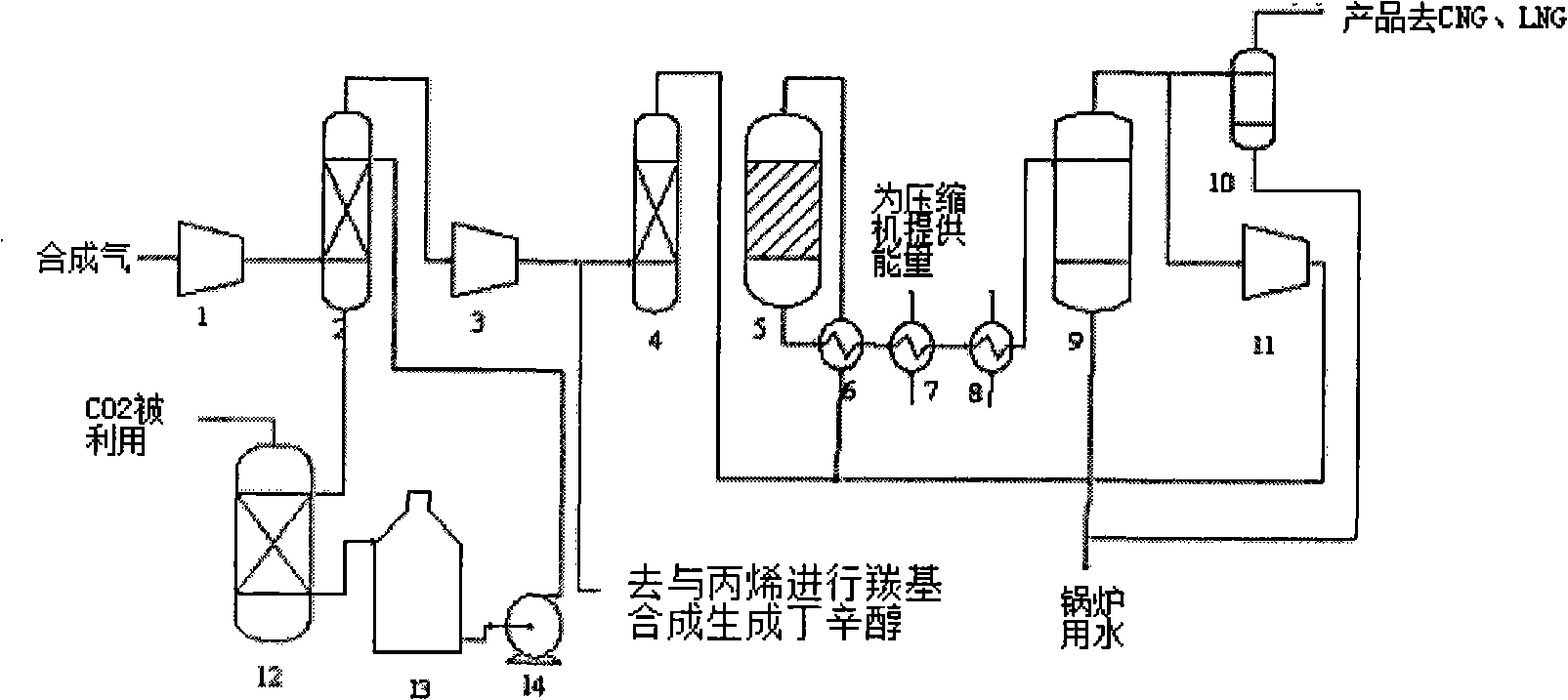

Method used

Image

Examples

Embodiment 1

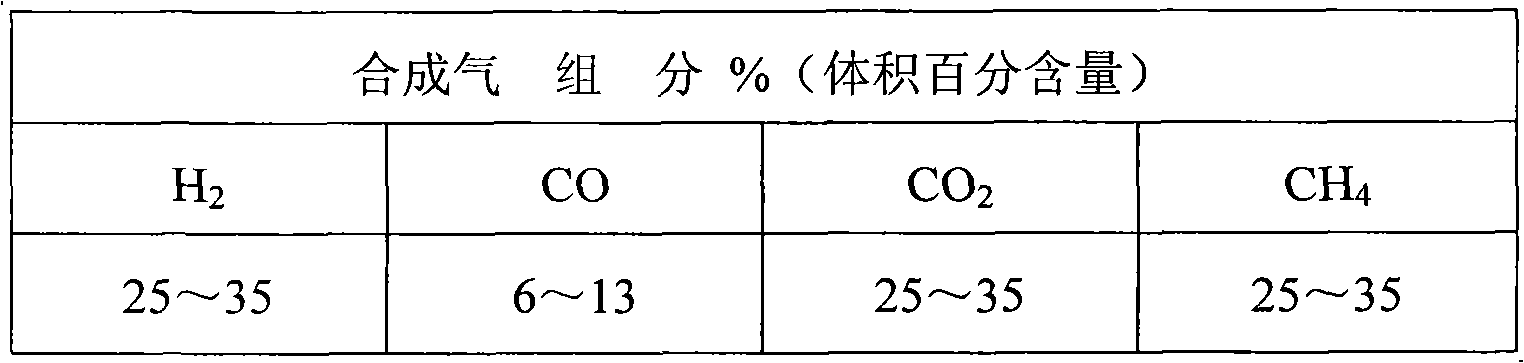

[0031] Production of 30,000 Nm from syngas from catalytic gasification 3 methane on a daily scale.

[0032] 07,000 Nm to the oxo synthesis section 3 / Day scale H 2 Syngas with / CO of 3.0 to 3.1;

[0033] In the decarburization section can produce 26,400 m 3 / Day CO 2 , used as gas tobacco leavening agent, plant gas fertilizer, supercritical extractant, beverage additive, welding protective gas, production of foam board, fruit and vegetable fresh-keeping agent, production of inorganic chemical products, borax, organic chemical products (dicyandiamide, salicylic acid , methanol, formic acid and its derivatives, etc.), carbon dioxide huff and puff, displacement oil recovery or oilfield recovery aids, etc.;

[0034] The amount of water produced is 5.62 tons / day, which is used as boiler water;

[0035] The heat generated is 6.4×10 7 KJ, the heat is partially recovered in the form of steam and hot water, which can by-produce and recover steam and hot water of different grades...

Embodiment 2

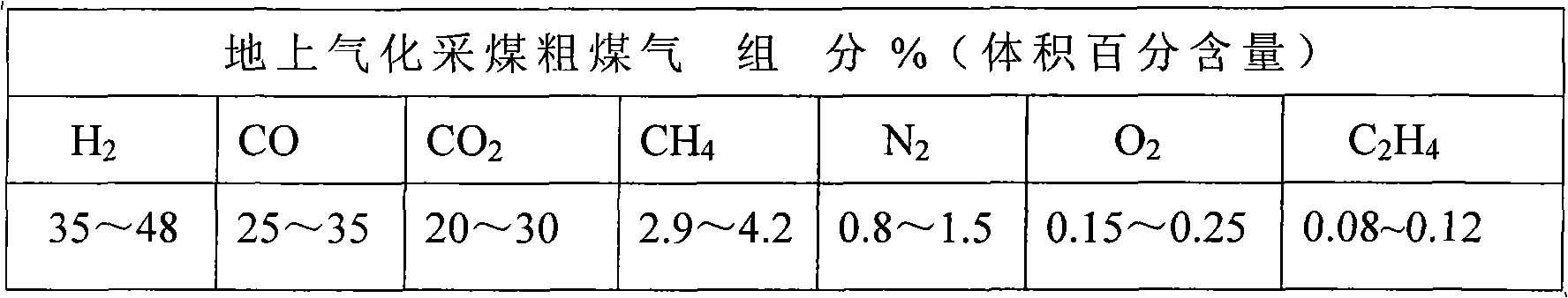

[0041] Production of 30,000 Nm from syngas from underground gasification coal mining 3 methane on a daily scale.

[0042] H from compound energy 2 39,900 Nm 3 / day;

[0043] 12,500 Nm to the oxo synthesis section 3 / Day scale H 2 Syngas with / CO of 3.0 / 1~3.1 / 1;

[0044] In the decarburization section can produce 26,400 m 3 / Day CO 2 , used as gas tobacco leavening agent, plant gas fertilizer, supercritical extractant, beverage additive, welding protective gas, production of foam board, fruit and vegetable fresh-keeping agent, production of inorganic chemical products, borax, organic chemical products (dicyandiamide, salicylic acid , methanol, formic acid and its derivatives, etc.), carbon dioxide huff and puff, displacement oil recovery or oilfield recovery aids, etc.;

[0045] The water produced is 21.1 tons / day, which can be used as boiler water;

[0046] Heat generation is 2.4×10 8KJ, the heat is partially recovered in the form of steam and hot water, which can by...

Embodiment 3

[0052] Production of 30,000 Nm from syngas from catalytic gasification and gasification coal mining 3 methane on a daily scale.

[0053] H from compound energy 2 21,800 Nm 3 / day;

[0054] 6,900 Nm to the oxo synthesis section 3 / Day scale H 2 Syngas with / CO of 3.0 / 1~3.1 / 1;

[0055] In the decarburization section can produce 24,400 m 3 / Day CO 2 , used as gas tobacco leavening agent, plant gas fertilizer, supercritical extractant, beverage additive, welding protective gas, production of foam board, fruit and vegetable fresh-keeping agent, production of inorganic chemical products, borax, organic chemical products (dicyandiamide, salicylic acid , methanol, formic acid and its derivatives, etc.), carbon dioxide huff and puff, displacement oil recovery or oilfield recovery aids, etc.;

[0056] The amount of water produced is 12.6 tons per day, which is used as boiler water;

[0057] Heat generation is 1.4×10 8 KJ, the heat is partially recovered in the form of steam an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com