Preparation method of controllable yttrium silicate nano-rod

A technology of yttrium silicate and nanorods is applied in the field of preparation of yttrium silicate nanorods, which can solve the problems of reports that have no influence on the process structure, complicated preparation methods and less involved in the morphology of yttrium silicate, etc. The effect of controllable particle morphology, simple process preparation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

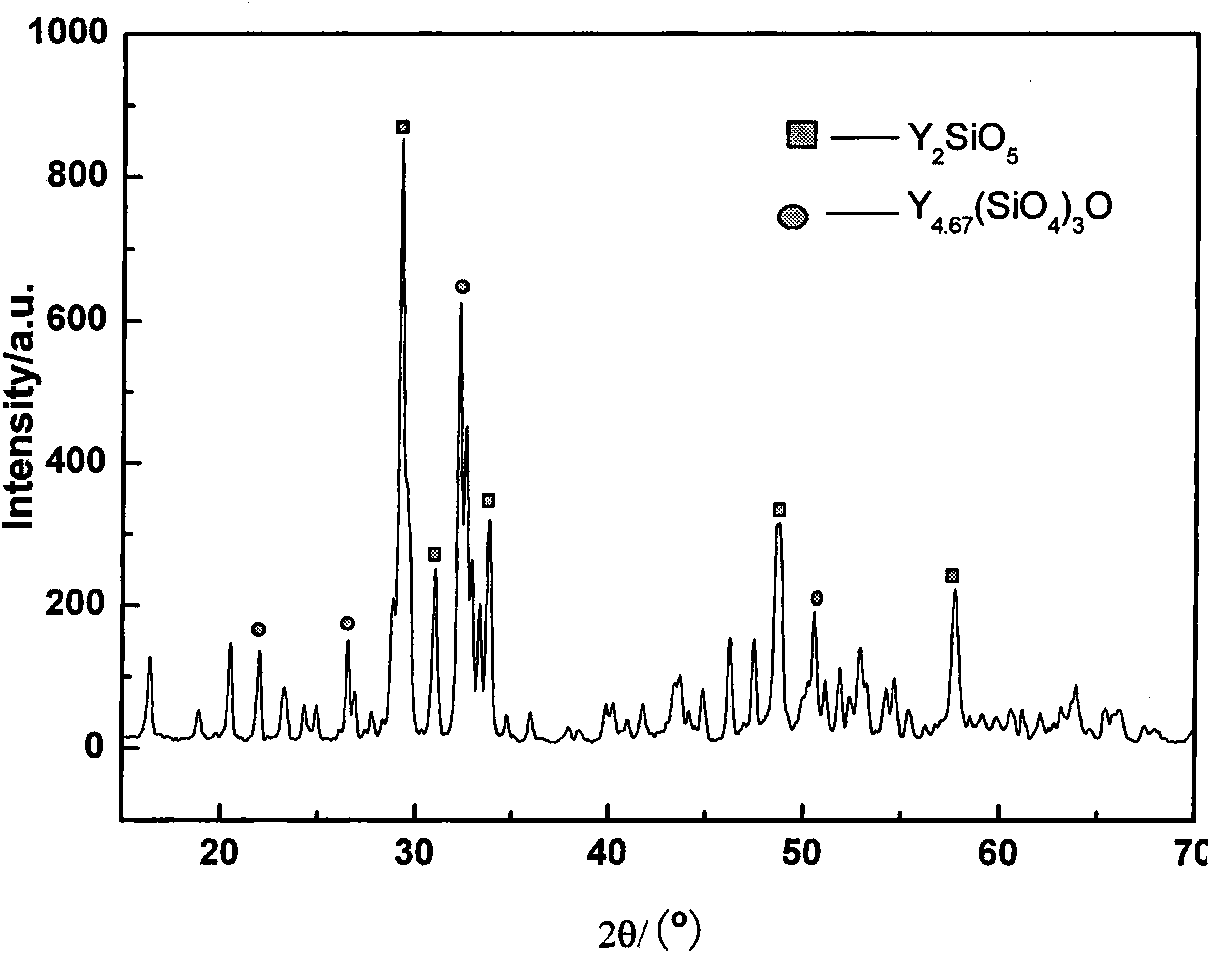

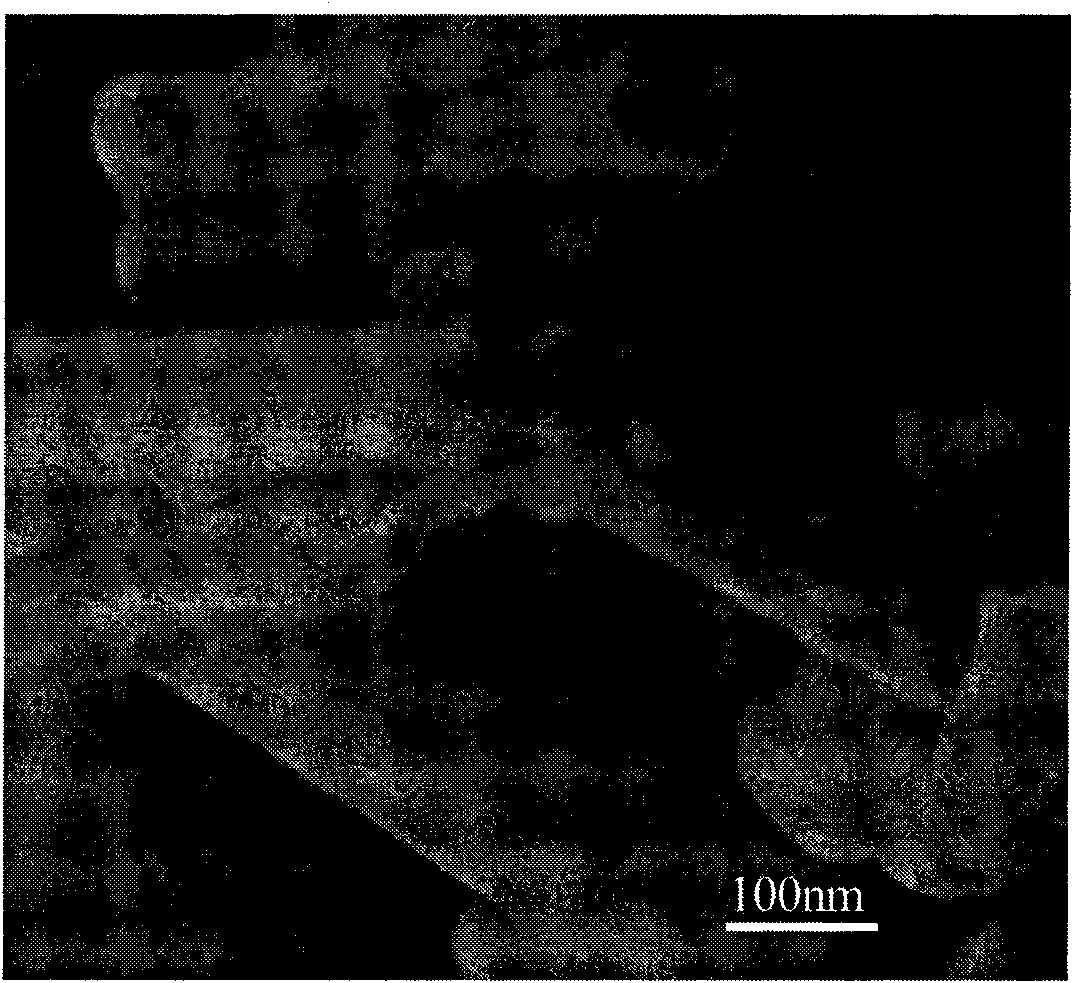

Embodiment 1

[0016] Embodiment 1: at first, analytically pure Y (NO 3 ) 3 ·6H 2 O, Na 2 SiO 3 9H 2 Add O and NaOH into distilled water respectively, and keep stirring to prepare a transparent solution with a concentration of 0.5mol / L, in which Y(NO 3 ) 3 :Na 2 SiO 3 : The mol ratio of NaOH is 2: 1: 4, utilizes the nitric acid that mass concentration is 20% and the ammoniacal liquor of 0.1mol / L to adjust its pH value to be 10.01, and the gained solution is denoted as A; Secondly, the A solution of above-mentioned preparation is poured into In the hydrothermal reaction kettle, the filling degree is controlled at 60%, and then the hydrothermal reaction kettle is sealed, and it is placed in a temperature-pressure dual-control microwave hydrothermal reactor, and the hydrothermal temperature is controlled at 180°C for 25 minutes. After the reaction, it will naturally After cooling to room temperature, the resulting solution was designated as B; then, the hydrothermal reaction vessel was ...

Embodiment 2

[0018] Embodiment 2: at first, analytically pure Y (NO 3 ) 3 ·6H 2 O, Na 2 SiO 3 9H 2 Add O and NaOH into distilled water respectively, and keep stirring to prepare a transparent solution with a concentration of 0.7mol / L, in which Y(NO 3 ) 3 :Na 2 SiO 3 : The mol ratio of NaOH is 2: 2: 2, utilizes mass concentration to be that the nitric acid of 20% and the ammoniacal liquor of 0.1mol / L regulate its pH value to be 6.40, and the gained solution is denoted as A; Secondly, the A solution of above-mentioned preparation is poured into In the hydrothermal reaction kettle, the filling degree is controlled at 80%, and then the hydrothermal reaction kettle is sealed, and it is placed in a temperature-pressure dual-control microwave hydrothermal reaction instrument, and the hydrothermal temperature is controlled at 120°C for 60 minutes. After the reaction, it will naturally After cooling to room temperature, the resulting solution was denoted as B; then, the hydrothermal reactio...

Embodiment 3

[0019] Embodiment 3: at first, analytically pure Y (NO 3 ) 3 ·6H 2 O, Na 2 SiO 3 9H 2 Add O and NaOH to distilled water respectively, and keep stirring to prepare a transparent solution with a concentration of 0.6mol / L, in which Y(NO 3 ) 3 :Na 2 SiO 3: The mol ratio of NaOH is 2: 1.3: 6, utilizes mass concentration to be that the nitric acid of 20% and the ammoniacal liquor of 0.1mol / L regulate its pH value to be 4, and the gained solution is denoted as A; Next, the A solution of above-mentioned preparation is poured into In the hydrothermal reaction kettle, the filling degree is controlled at 40%, then the hydrothermal reaction kettle is sealed, and it is placed in a microwave hydrothermal reaction instrument with dual temperature and pressure control, and the hydrothermal temperature is controlled at 210°C for 10 minutes. After cooling to room temperature, the resulting solution was designated as B; then, the hydrothermal reaction vessel was opened, and the product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com