Method for preparing extrafine anatase titanium dioxide nano rods

A technology of titanium dioxide and anatase phase, applied in the direction of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problem that the high density of the film affects the photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

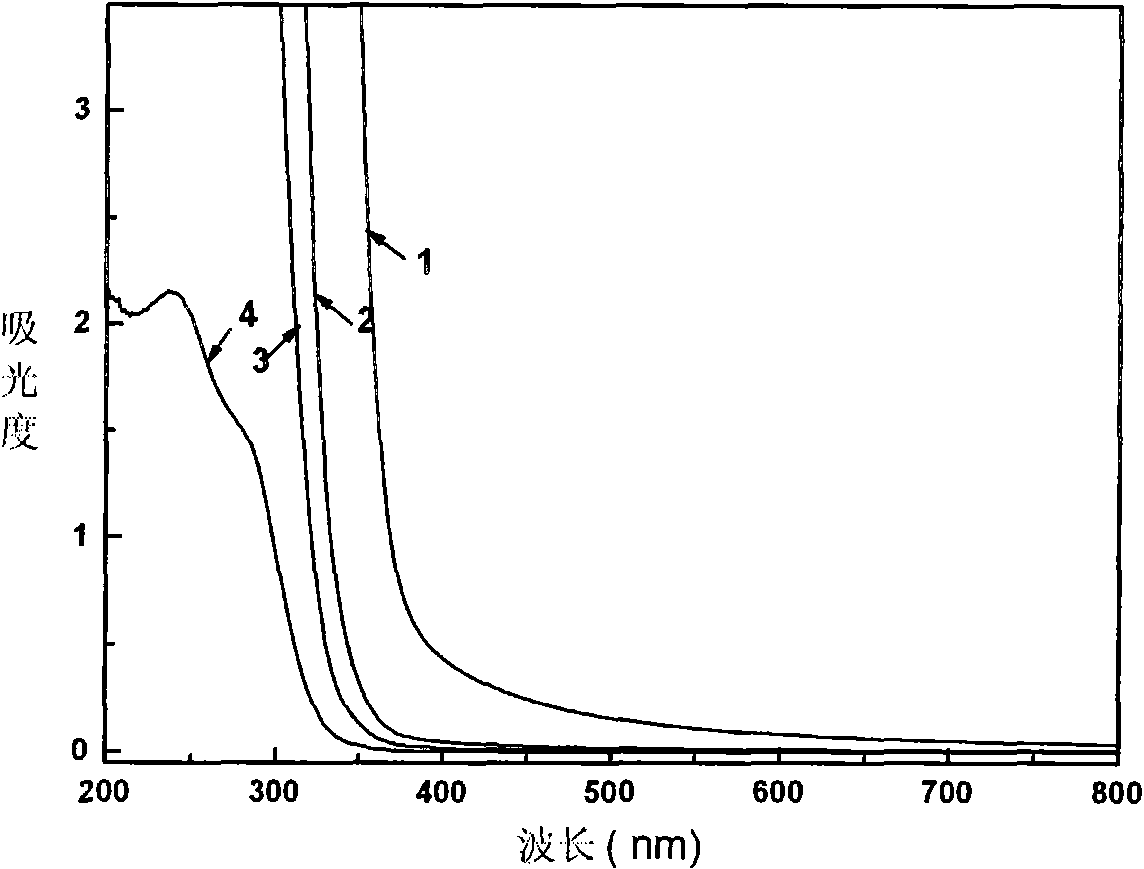

[0032]Add dropwise 1M sodium hydroxide solution to 0.5M titanium tetrachloride solution at room temperature, neutralize until the pH value is approximately equal to 7, obtain a white precipitate, wash repeatedly with distilled water to obtain a gelatinous solid, take 30 grams of wet precipitate (equivalent to It is 4 grams) to be dispersed in 180 milliliters of hydrogen peroxide (30%) in 180 milliliters of hydrogen peroxide (30%), at 30 ℃ of degumming 6 hours, obtain the peroxotitanic acid aqueous solution of orange-yellow transparency, the content of titanium dioxide in the solution is 0.24M, pH value about 6. Then dilute peroxotitanic acid aqueous solution and deionized water respectively according to the mass ratio of 1:5, measure 50mL and put it into a hydrothermal reaction kettle, after 150°C hydrothermal treatment for 4h, after hydrothermal cooling to room temperature, light blue transparent sol, The concentration of titanium dioxide was 0.041M. After diluting different...

Embodiment 2

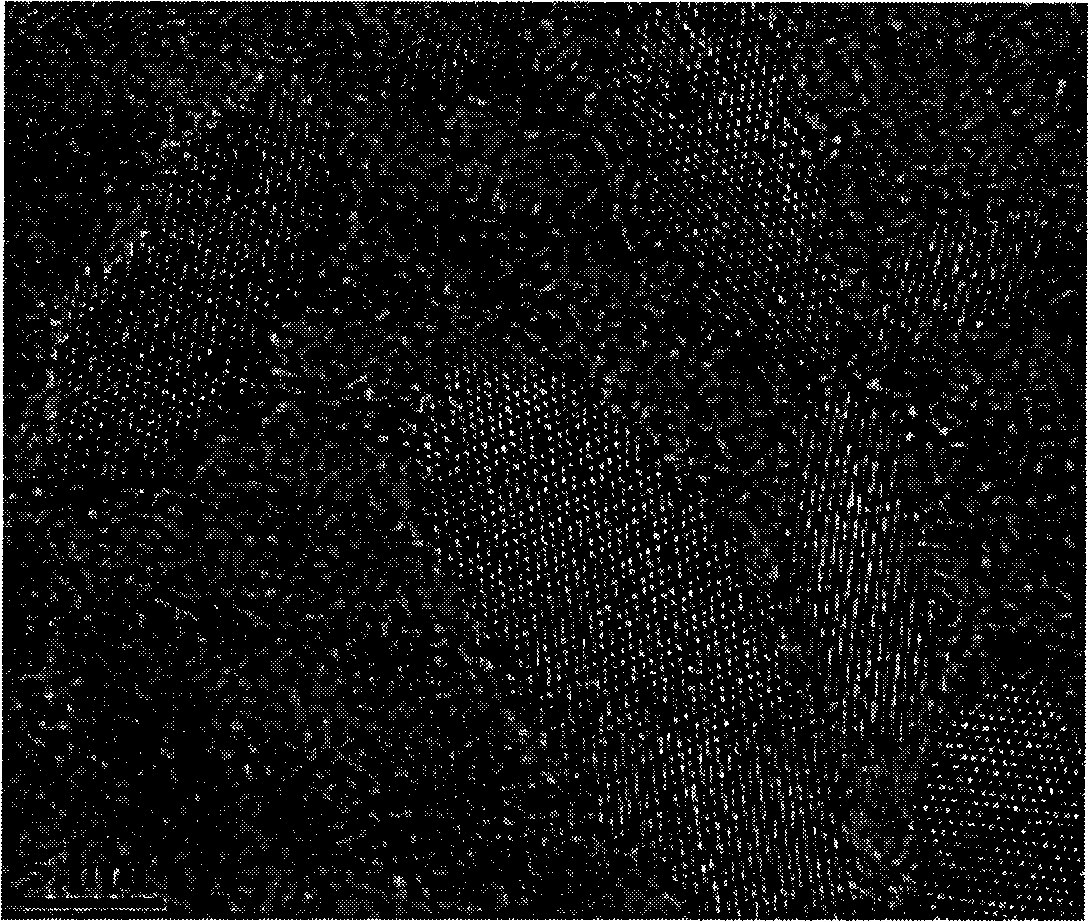

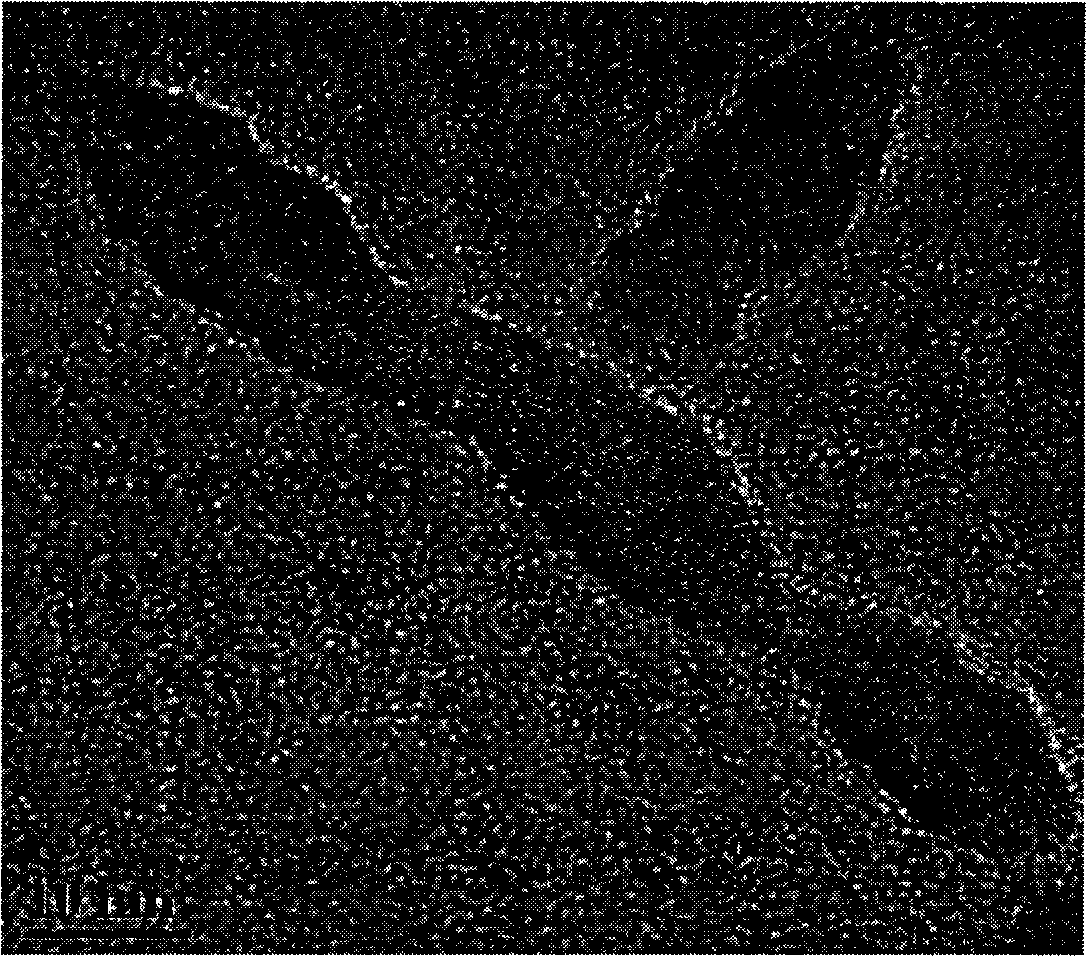

[0035] Add 2M ammonia water dropwise to 1M titanyl sulfate solution at 70°C, keep warm and hydrolyze for 6 hours, neutralize to a weakly alkaline pH value of about 8, and obtain a white precipitate, wash it repeatedly with distilled water to obtain a gel-like solid, take the wet precipitate 15 grams (2 grams converted into titanium dioxide) were dispersed in about 90 milliliters of hydrogen peroxide (35%), degummed at room temperature for 2 hours to obtain an orange-yellow transparent peroxotitanic acid hydrosol, with a pH value of about 6 . Then dilute peroxotitanic acid aqueous solution and deionized water according to the mass ratio of 1:4 respectively, measure 50mL and put it into a hydrothermal reaction kettle, after 120°C hydrothermal treatment for 4h, after hydrothermal cooling to room temperature, a light blue transparent sol, The concentration of titanium dioxide was 0.05M. The titanium dioxide contained therein is anatase phase through transmission electron microsco...

Embodiment 3

[0037] After raising the temperature of 0.5 mol / L titanium sulfate solution to 50°C, add 1.5 mol / L ammonia solution dropwise to the solution, keep it warm for 10 hours for hydrolysis, neutralize until the pH value is about equal to 7, and obtain a white precipitate, which is washed repeatedly with distilled water to obtain Gel-like solid, get wet precipitate 40 grams (converted into titanium dioxide to be 6.2 grams) and disperse it in 280 milliliters of hydrogen peroxide (35%) solution, degumming 12 hours, obtain orange-yellow transparent peroxotitanic acid hydrosol, pH The value is about 6. Then dilute peroxotitanic acid aqueous solution and deionized water respectively according to the mass ratio of 1:8, measure 50mL and put it into a hydrothermal reaction kettle, undergo hydrothermal treatment at 120°C for 4h, then undergo hydrothermal treatment at 180°C for 24h, and then cool to Light blue transparent sol at room temperature, the concentration of titanium dioxide is 0.042M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com