A liquid light-to-heat conversion material and its preparation method and application

A photothermal conversion material, liquid technology, applied in chemical instruments and methods, other chemical processes, photometry using electrical radiation detectors, etc., can solve the problems of wear, inconvenience, poor deformation performance, etc. It has the advantages of great application prospect and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

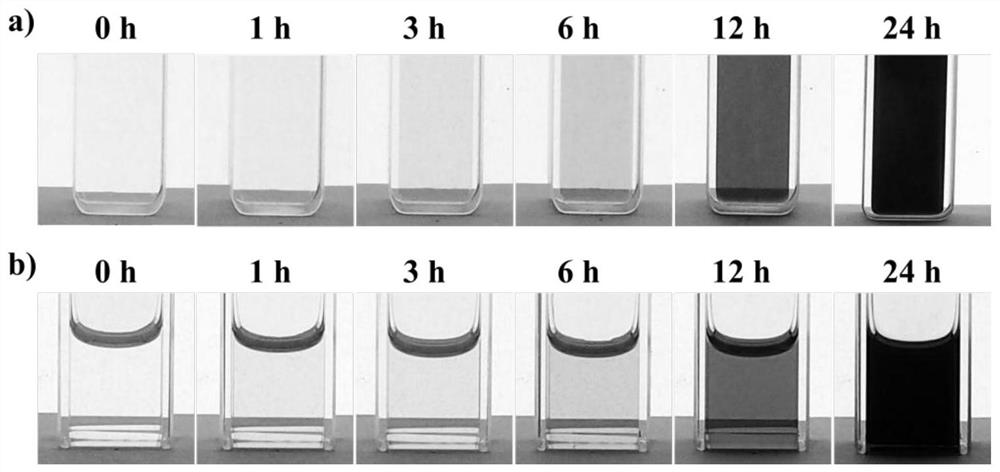

[0039] Smoke iodine respectively (1 second to 1 week, specifically 0 , 1, 3, 6, 12, 24h) oleic acid and ethyl oleate (0.001mL~10 6 mL) to obtain a liquid light-to-heat conversion material with a certain amount of iodine doping (mass percentage of iodine doping is 0.1-1000%, specifically 50%).

[0040] The physical picture of the liquid photothermal conversion material obtained above is as follows: figure 1 shown.

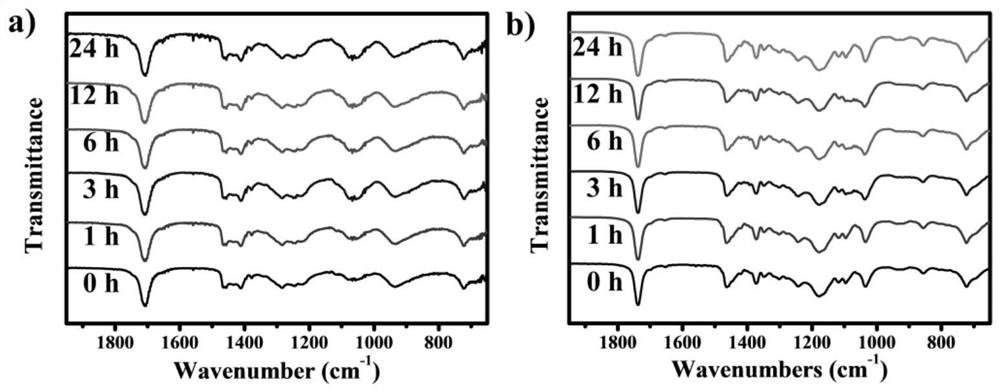

[0041] iodine

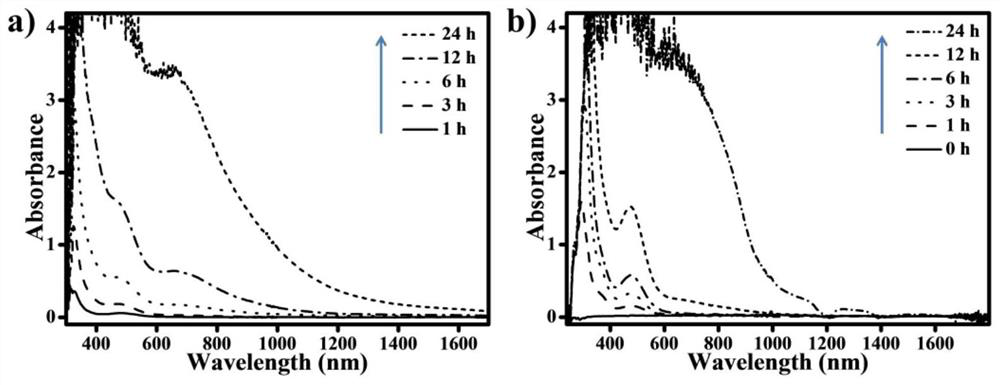

[0042] Depend on Figure 2-4 It can be seen that the light absorption wavelength of the liquid photothermal conversion material may be 200-1800 nm.

[0043] Depend on Figure 5It can be known that the viscosity of the liquid light-to-heat conversion material may be 1.0-30.0 mPa·s.

[0044] Depend on Figure 6 It can be seen that the electrical conductivity of the liquid photothermal conversion material can be 0.0001-1 S / m.

Embodiment 2

[0045] Example 2. Preparation and Application of Anti-icing Coating of Small Molecule Liquid Photothermal Conversion Material

[0046] At a certain temperature (0-200°C, specifically 65°C) and iodine vapor pressure (0.01-20kPa, specifically 0.75Pa), smoke iodine with different durations (1 second to 1 week, specifically can be 0, 1, 3, 6, 12, 24h) oleic acid and ethyl oleate were soaked respectively (1 second to 1 week, specifically 0, 1, 3, 6, 12, 24h) with a certain thickness (0.001mm ~ 10cm) substrate, that is, to obtain an anti-icing coating with light-to-heat conversion capability, such as Figure 7 shown. The material has a certain amount of iodine doping (mass percentage of iodine doping is 0.1-1000%, specifically 50%). Substrates for this coating include paper, wood boards, rubber, polydimethylsiloxane (PDMS), Ecoflex products, and more.

[0047] Fluke Tix 660 infrared camera is used to collect CROWNTECH SOLARBEAM-02-3A solar simulator a solar light intensity irradi...

Embodiment 3

[0049] Example 3. Preparation and application of photothermal conversion liquid photothermal conversion material light intensity detector

[0050] Smoked iodine (1 second to 1 week, specifically 0, 1, 3, 6, 12, 24h) ethyl oleate (0.001mL~ 10 6 mL) is packaged in a self-made device to obtain a light intensity detector that can detect light intensity, such as Figure 9 shown. The self-made device includes a display part and a light receiving part. The display part is a tubular object with certain specifications (material: glass, quartz, metal, polymer material, length: 0.001-1000m, outer diameter: 0.001-100cm, inner diameter: 0.001-100cm). The light receiving part is a special bottle with certain specifications (material: glass, quartz, metal, polymer material, length: 0.001-1000m, outer diameter: 0.001-100cm, inner diameter: 0.001-100cm). After the photothermal conversion small molecule liquid black material is exposed to light, the temperature rises, thereby changing the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com