Fermentation method for producing high viscocity xanthan gum by xanthomonas campestris

A technology of Xanthomonas and fermentation method, which is applied in the field of microbial fermentation engineering to produce xanthan gum, can solve problems such as shortening the fermentation cycle, and achieve the effects of reducing raw material costs and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

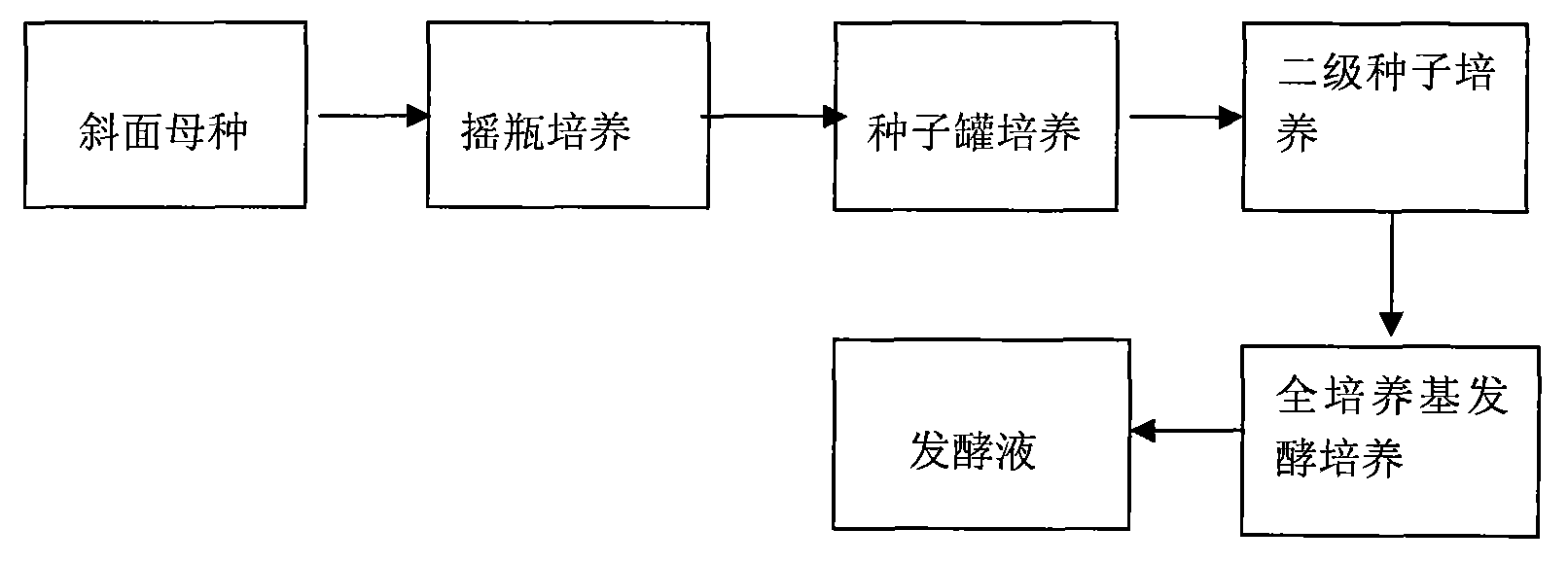

[0041] The present invention adopts secondary fermentation method

[0042] Shake flask culture: prepare 3L of shake flask medium, shake flask medium components (g / L volume to weight ratio):

[0043] Glucose 15; Hydrolyzed Soybean Peptone 20; NaCl 10;

[0044] Adjust the pH to 7.0, divide into 6 parts, sterilize, connect 1ml glycerol tube working seeds on the ultra-clean bench, culture at 30°C for 16 hours;

[0045] Seed tank culture: Seed medium components (g / L volume to weight ratio):

[0046] Glucose 15; Hydrolyzed Soybean Peptone 20; NaCl 10;

[0047] Prepare 600L of seed medium in a 1000L fermenter, adjust the pH to 7.0, sterilize, insert the seed liquid in a shaker flask, stir at 150-250 rpm, aerate at 0.3vvm, 30°C, cultivate for 8-10 hours, and the total OD reaches 4.03 Transplantation;

[0048] Fermentation culture: basal fermentation medium components (g / L volume to weight ratio):

[0049] Glucose 10; hydrolyzed soybean peptone 1; urea 2; corn steep liquor powder ...

Embodiment 2

[0060] Except for changing the single factor, the other components of the medium remained unchanged, and they were all sterilized at 121°C for 20 minutes;

[0061] Shake flask culture: prepare 3L of shake flask culture medium, adjust the pH to 7.0, divide into 6 parts, sterilize, connect 1ml glycerol tube working seeds on the ultra-clean bench, culture at 30°C for 16hr;

[0062] Seed culture: Prepare 600L of seed medium in a 1000L fermenter, adjust the pH to 7.0, sterilize, insert the seed liquid in a shaker flask, stir at 150-250 rpm, aerate at 0.3vvm, 30°C, cultivate for 8-10hr, total 0D to 4.21 transplant;

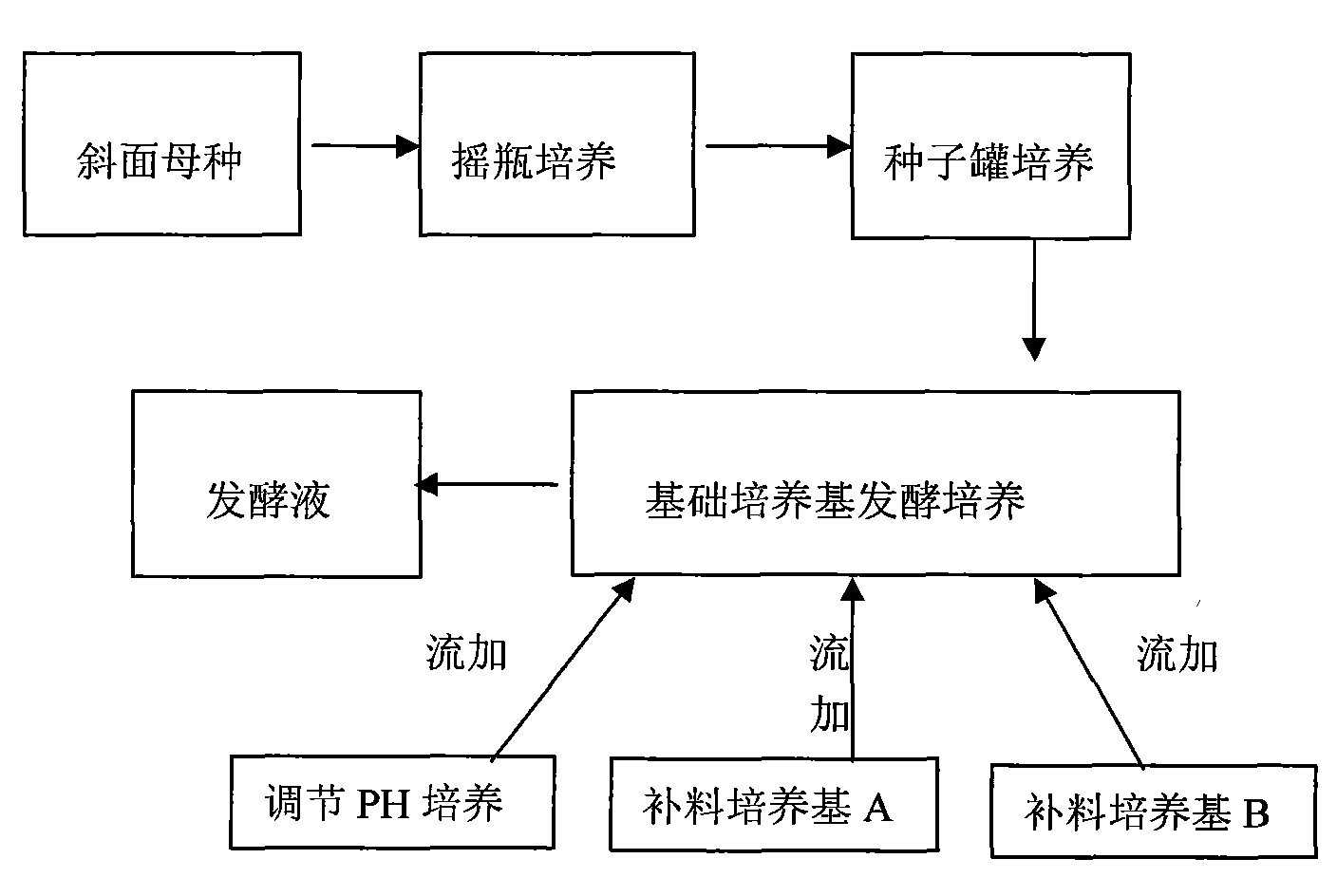

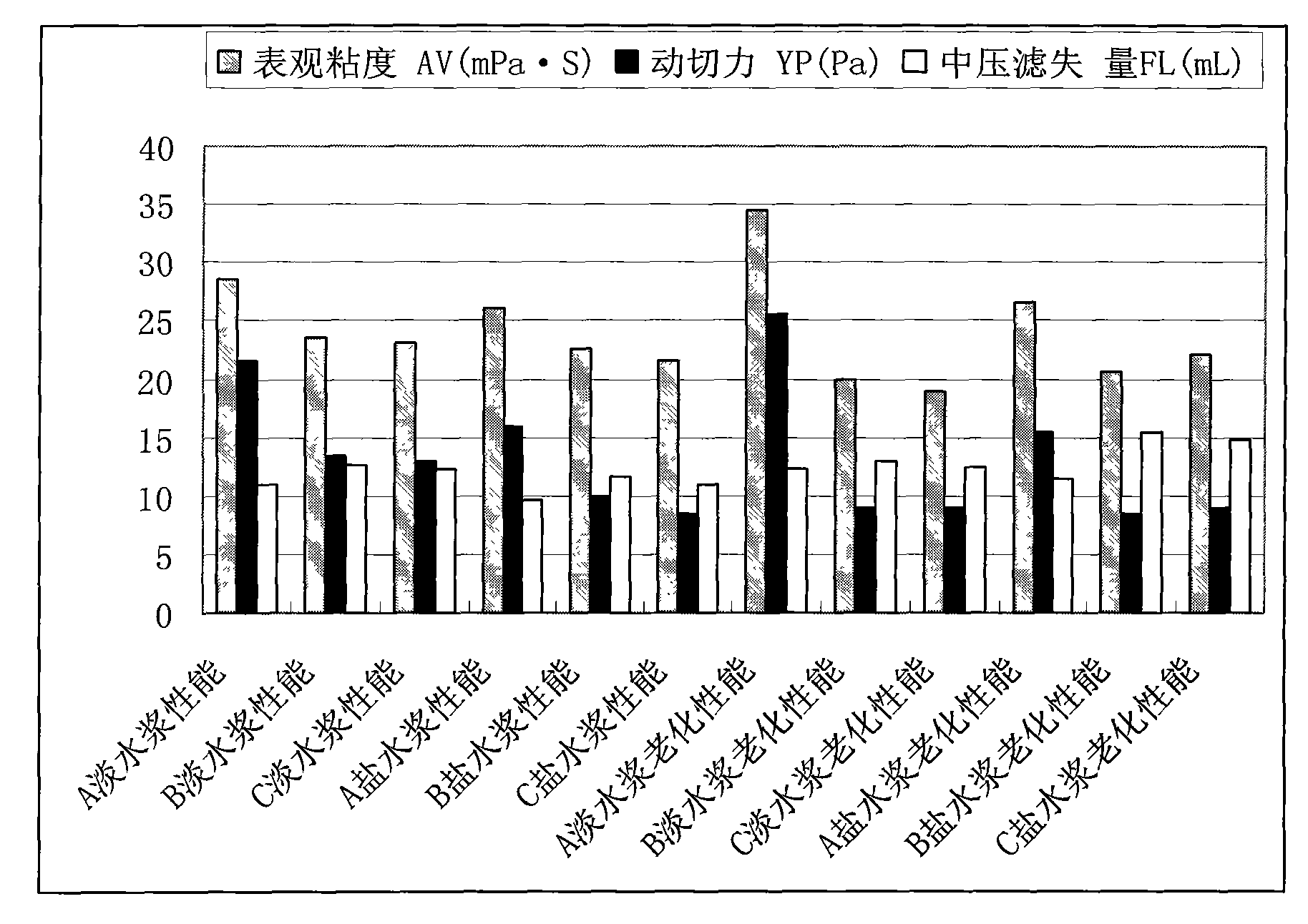

[0063] Fermentation culture: Prepare 6 tons of fermentation medium in a 10-ton fermenter, prepare 1 ton of feed medium A in two 600L feed tanks, 5% foam in 50L foam tanks, empty the acid-base tank, and eliminate Bacteria, the seed solution was transplanted into the sterilized fermentation medium, 100-150 rpm, aeration 0.3-0.6vvm, pH adjusted to 6.9, 30°C culture; at th...

Embodiment 3

[0065] Except for changing the single factor, the other components of the medium remained unchanged, and they were all sterilized at 121°C for 20 minutes;

[0066] Shake flask culture: prepare 3L of shake flask culture medium, adjust the pH to 7.0, divide into 6 parts, sterilize, connect 1ml glycerol tube working seeds on the ultra-clean bench, culture at 30°C for 16hr;

[0067] Seed culture: Prepare 600L of seed medium in a 1000L fermenter, adjust the pH to 7.0, sterilize, insert the seed liquid in a shaker flask, stir at 150-250 rpm, aerate at 0.3vvm, 30°C, cultivate for 8-10hr, total OD to 4.18 transplantation;

[0068] Fermentation culture: Prepare 6 tons of fermentation medium in a 10-ton fermenter, prepare 1 ton of feed medium A in two 600L feed tanks, 5% foam in 50L foam tanks, empty the acid-base tank, and eliminate Bacteria, the seed solution was transplanted into the sterilized fermentation medium, 100~150 rpm, aeration 0.3~0.6vvm, pH adjusted to 7.2, 30°C culture; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com