Method for preparing cathode catalyst of proton exchange membrane fuel cell

A fuel cell cathode and proton exchange membrane technology, applied in catalyst activation/preparation, battery electrodes, chemical instruments and methods, etc., can solve the problems of high temperature, complicated procedures, cumbersome processes, etc., and achieve simple operation, low preparation cost, The effect of improving the reducing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

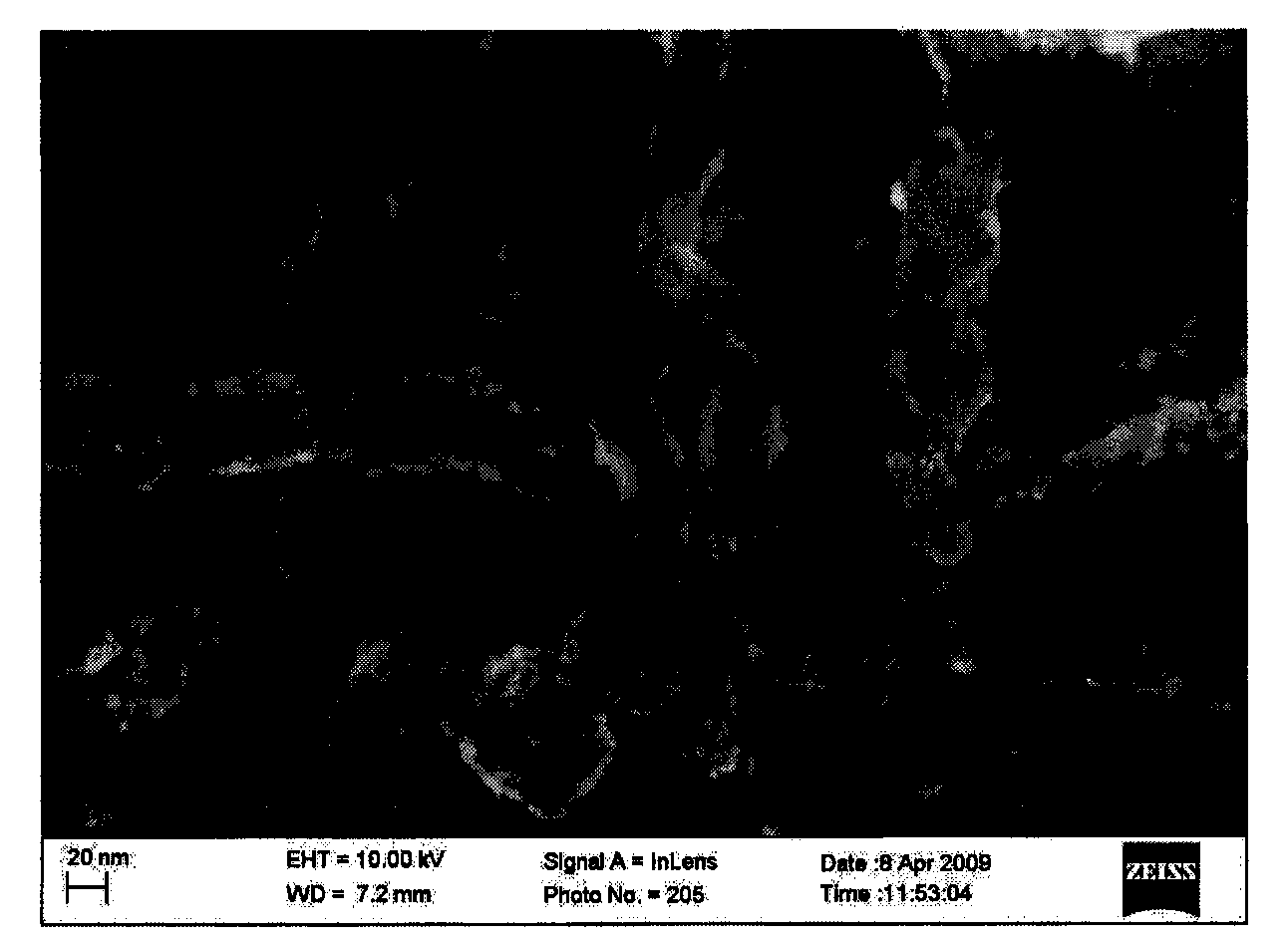

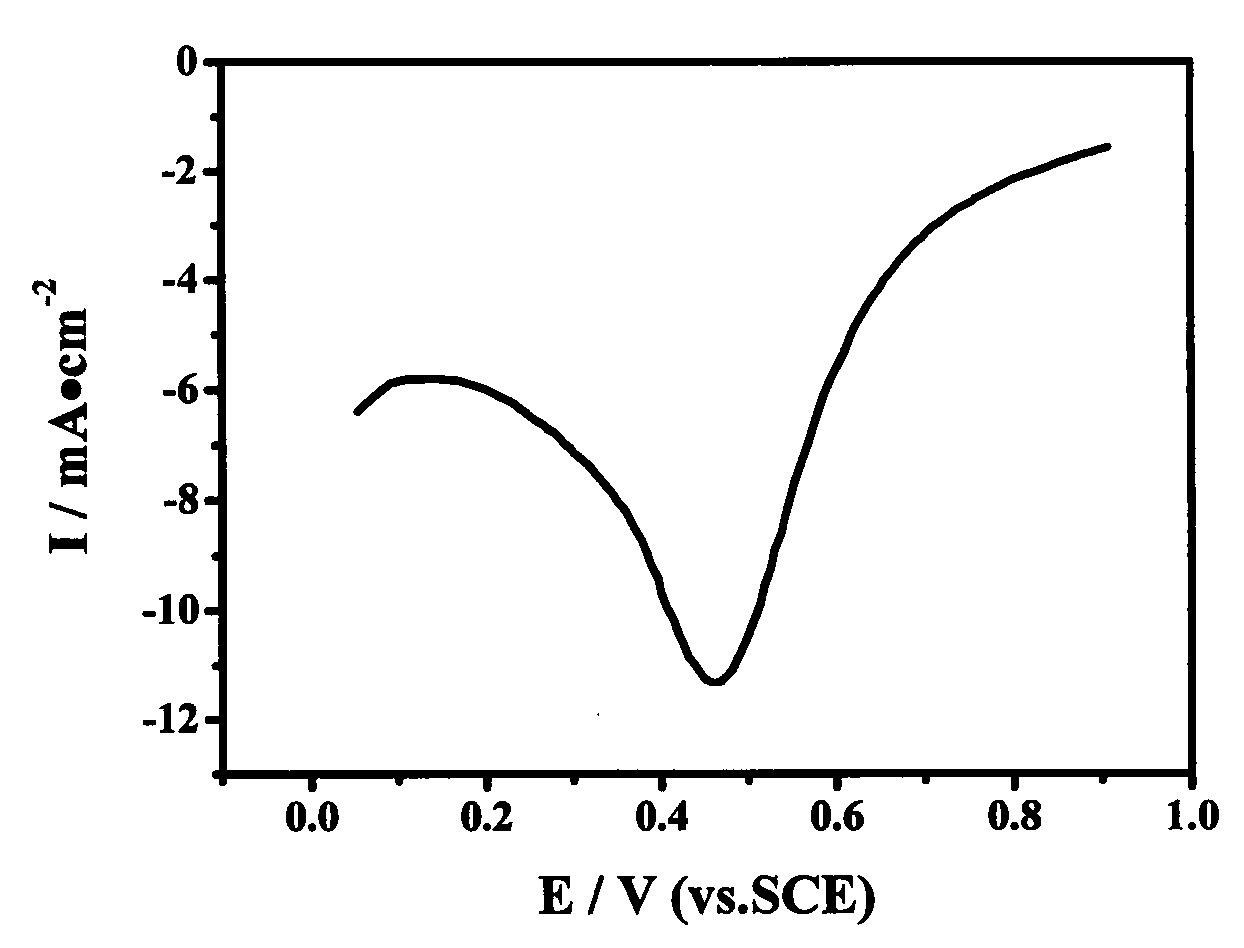

[0027] Preheat the carbon nanotubes at 800°C for 20 minutes; mix 6 milliliters of ethylene glycol and 9 milliliters of water to prepare 15 milliliters of organic solvent, then add 18 milligrams of pretreated carbon nanotubes to the organic solvent, and ultrasonically disperse them for 30 minutes. into a carbon slurry; measure 3.0 milliliters of chloroplatinic acid solution (5 mg platinum / ml) mixed with an organic solvent, add dropwise to the carbon slurry, and disperse with ultrasonic waves for 30 minutes to form a mixed suspension. Under the condition of argon stirring, add 5 ml of sodium hydroxide solution mixed with an organic solvent at a concentration of 1.0 mol / L, adjust the pH to 10, raise the temperature to 70°C, add dropwise 18 ml of a formic acid solution mixed with an organic solvent at a concentration of 0.75 mol / L, continue Stir for 12 hours, then cool to 50°C. The final product was washed with deionized water until there was no chloride ion in the washing solutio...

Embodiment 2

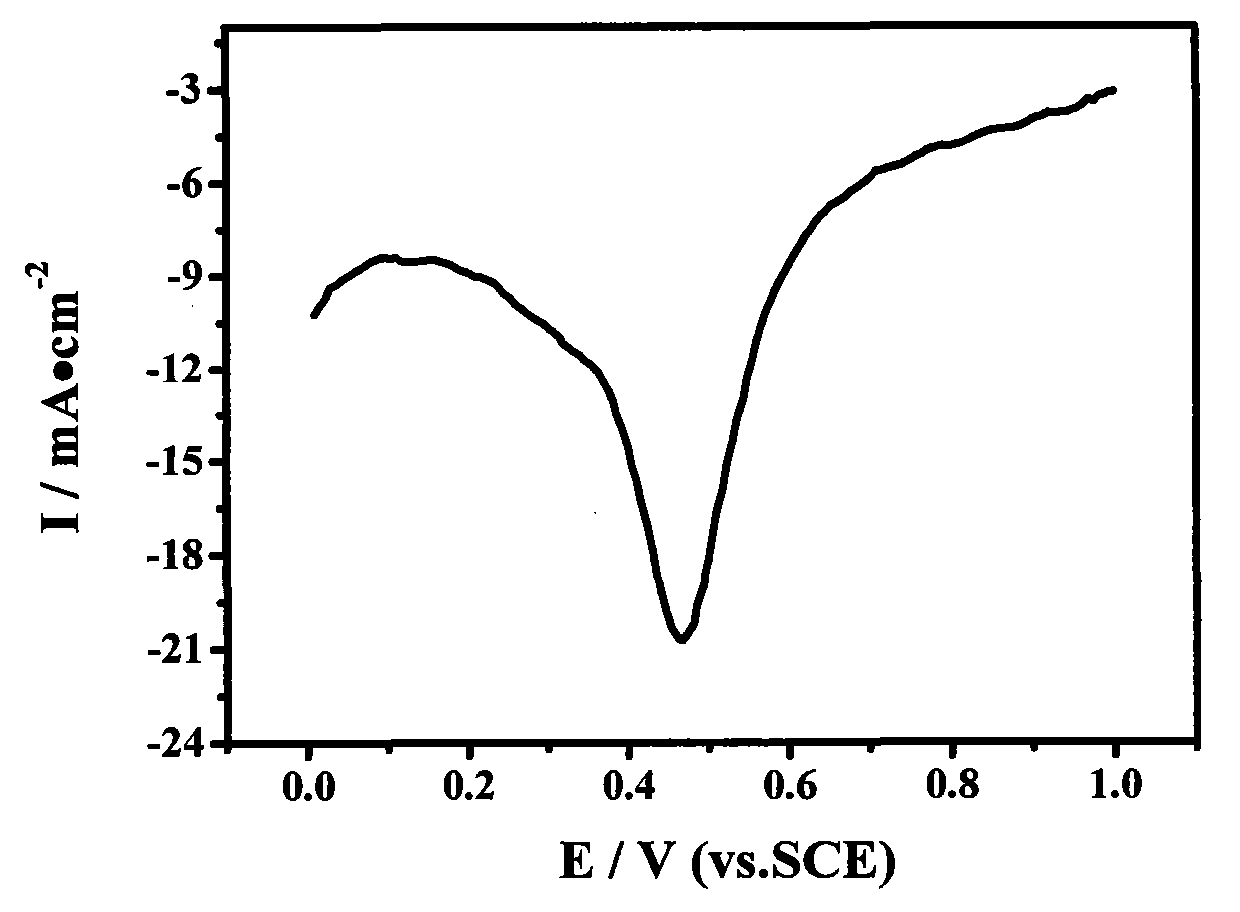

[0029] Preheat carbon nanotubes at 500°C for 60 minutes; mix 10 milliliters of ethylene glycol and 10 milliliters of water to prepare 20 milliliters of organic solvent, then add 20 milligrams of pretreated carbon nanotubes to the organic solvent, and ultrasonically disperse them for 60 minutes. into a carbon slurry; measure 2.0 milliliters of chloroplatinic acid solution (7.5 mg platinum / ml) mixed with an organic solvent, add dropwise to the carbon slurry, and disperse with ultrasonic waves for 60 minutes to form a mixed suspension. Under the condition of argon stirring, add 2 ml of sodium hydroxide solution mixed with an organic solvent at a concentration of 2.5 mol / L, adjust the pH to 12, raise the temperature to 90°C, add dropwise 50 ml of a formic acid solution mixed with an organic solvent at a concentration of 0.25 mol / L, continue Stir for 8 hours, then cool down to 30°C. The final product is washed with deionized water until there is no chloride ion in the washing liqui...

Embodiment 3

[0031]Pre-heat the carbon nanotubes at 700°C for 40 minutes; mix 18 milliliters of ethylene glycol and 12 milliliters of water to prepare 30 milliliters of organic solvent, then add 15 milligrams of pretreated carbon nanotubes to the organic solvent, and ultrasonically disperse them for 80 minutes. into a carbon slurry; measure 1.5 milliliters of chloroplatinic acid solution (10 mg platinum / ml) mixed with an organic solvent, add dropwise to the carbon slurry, and disperse with ultrasonic waves for 45 minutes to form a mixed suspension. Under the condition of argon stirring, add 2 ml of sodium hydroxide solution mixed with an organic solvent at a concentration of 0.5 mol / L, adjust the pH value to 13, raise the temperature to 110°C, add dropwise 25 ml of a formic acid solution mixed with an organic solvent at a concentration of 0.5 mol / L, continue Stir for 4 hours, then cool down to 40°C. The final product was washed with deionized water until there was no chloride ion in the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com