Decoquinate solid dispersoid and preparation method thereof

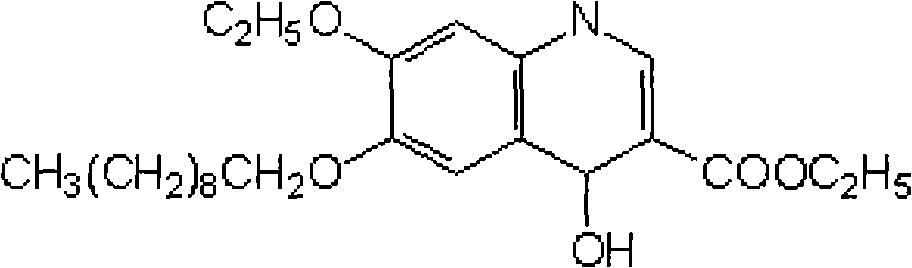

A solid dispersion and decoquinate technology, which is applied in the direction of medical preparations of non-active ingredients, active ingredients of heterocyclic compounds, pharmaceutical formulations, etc., can solve the problem that decoquinate is not easy to disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Decoxyquinate 47.0g

[0018] Polyvinylpyrrolidone K30 47.0g

[0019] Polysorbate 60 6.0g

[0020] Preparation method and steps: add 47 parts of polyvinylpyrrolidone to 30 parts of water, stir and mix evenly, heat until completely dissolved, add 47 parts of decoquinate and 6 parts of polysorbate 60 to the ethanol solution of polyvinylpyrrolidone under stirring After mixing, a semi-fluid substance is obtained, which is ground by a colloid mill until it is completely mixed, then the material is dried under reduced pressure, crushed through a 120-mesh sieve, and the obtained solid is the decoquinate solid dispersion.

Embodiment 2

[0022] Decoxyquinate 16.0g

[0023] Polyvinyl alcohol 80.0g

[0024] Sodium Lauryl Sulfate 4.0g

[0025] Preparation method and steps: add 80 parts of polyvinyl alcohol into 60 parts of water, dissolve completely, add decoquinate into the aqueous solution of polyvinyl alcohol under stirring, then add sodium lauryl sulfate, and grind through a colloid mill Make the mixture uniform, dry under reduced pressure, remove all water, and pulverize into fine powder to obtain decoquinate dispersion.

Embodiment 3

[0027] Decoxyquinate 10.0g

[0028] Polyethylene glycol (4000) 85.0g

[0029] Polysorbate 80 5.0g

[0030] Preparation method and steps: Add 85 parts of polyethylene glycol (4000) into 100 parts of water, heat until completely dissolved, and add decoquinate and polysorbate 80 into the solution containing polyethylene glycol (4000) under stirring. solution, continue to mix, grind through a colloid mill until the materials are uniformly mixed, and spray dry to obtain the decoquinate solid dispersion.

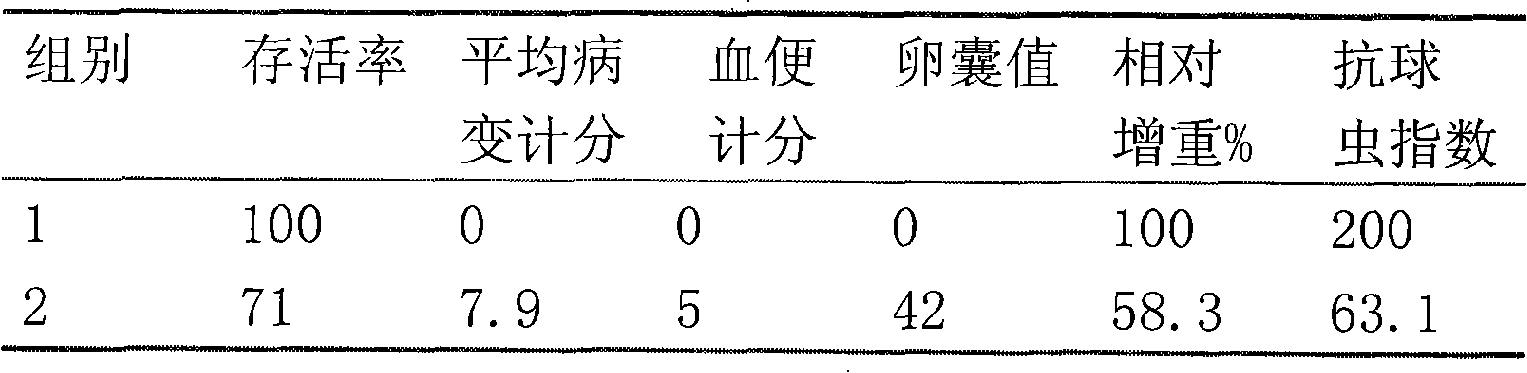

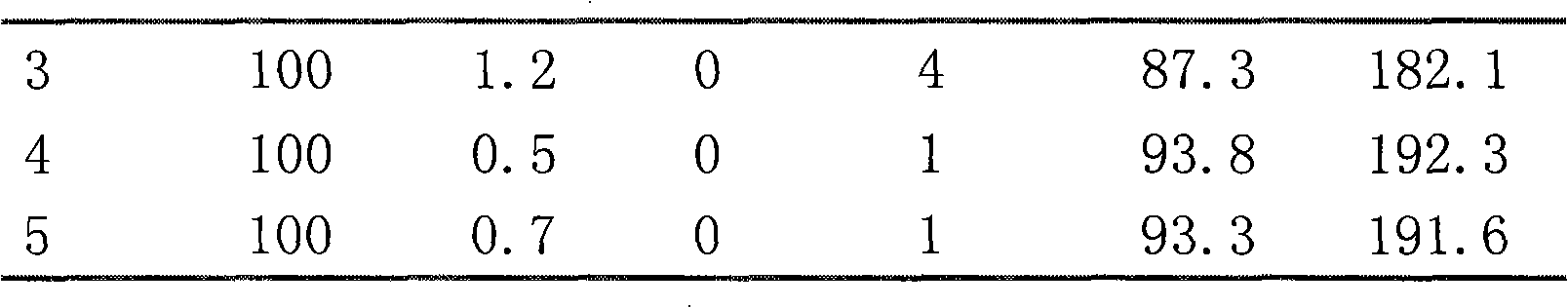

[0031] In order to verify the anti-coccidiostat effect of the product of the present invention, the product of the present invention was compared with two kinds of anticoccidial drugs of decoquinate premix and decoquinate solution, as follows:

[0032] Materials and Methods:

[0033] 1.1 Test chickens 60 1-day-old Avian broilers.

[0034] 1.2 Test drugs

[0035] Decoquinate premix: Yalai Pharmaceuticals, USA, containing 6.0% decoquinate;

[0036] Decoquinate solid dispersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com