Structure and method of using step electrodes to realize nanometer beam drive and pressure resistance detection

A piezoresistive detection and ladder-shaped technology, which is applied in the manufacture of nanostructures, the measurement of the properties and forces of applied piezoresistive materials, nanotechnology, etc., can solve the problem of reducing the quality of nanobeams and increasing the complexity of the process by protecting the oxide layer of the gate, etc. problems, to avoid the influence of stress distribution and quality factor, to avoid protection, and to simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

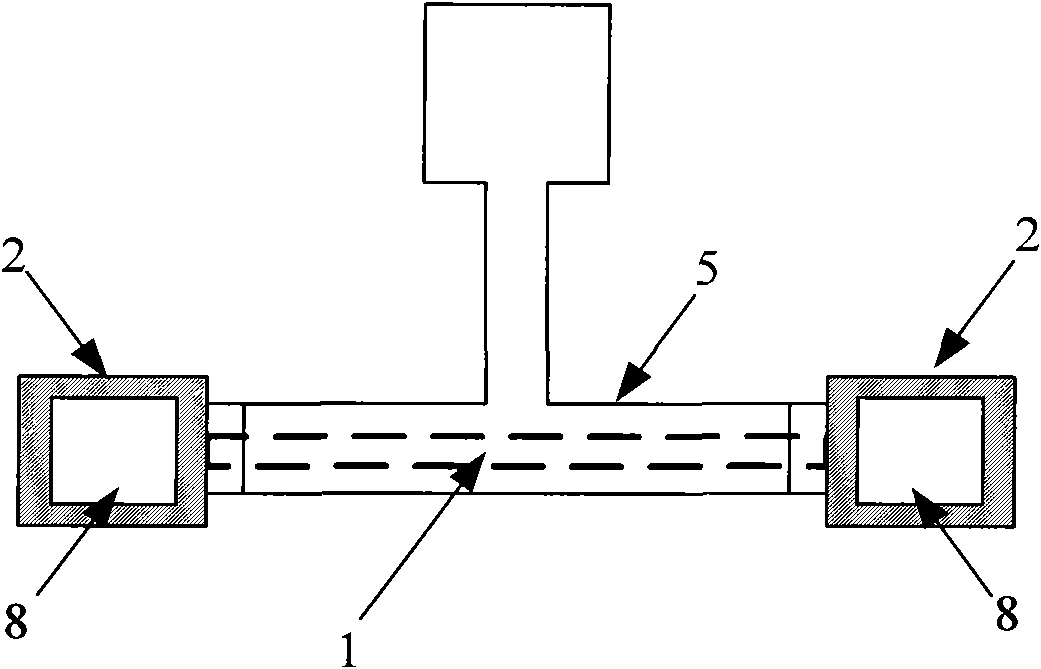

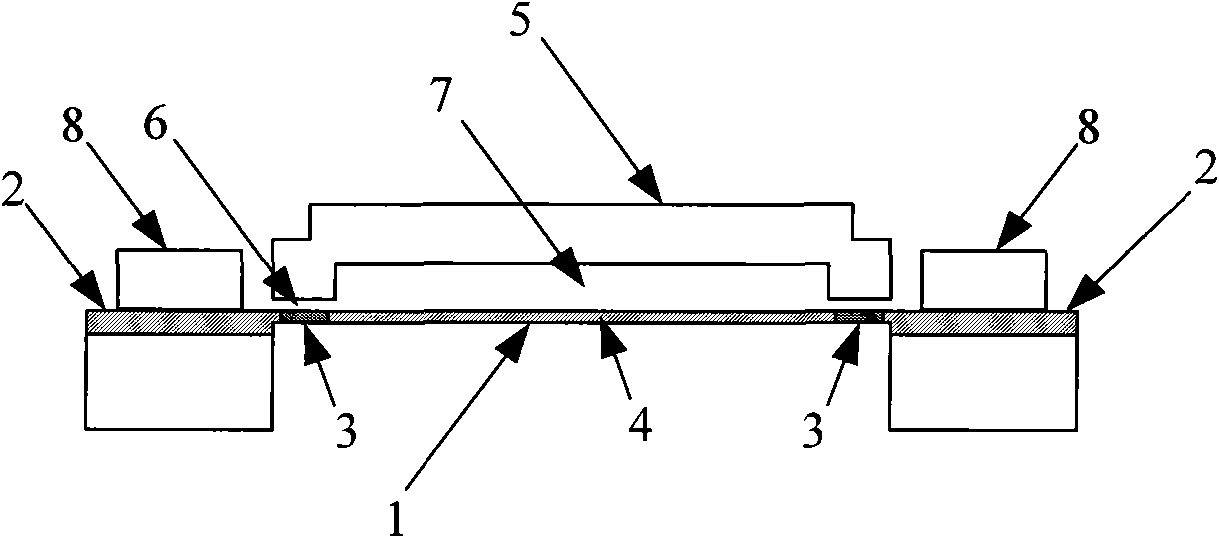

[0024] Embodiment 1 The manufacturing process steps of the double-terminal fixed-supported nano-beam driving and piezoresistive detection structure provided by the present invention are as follows:

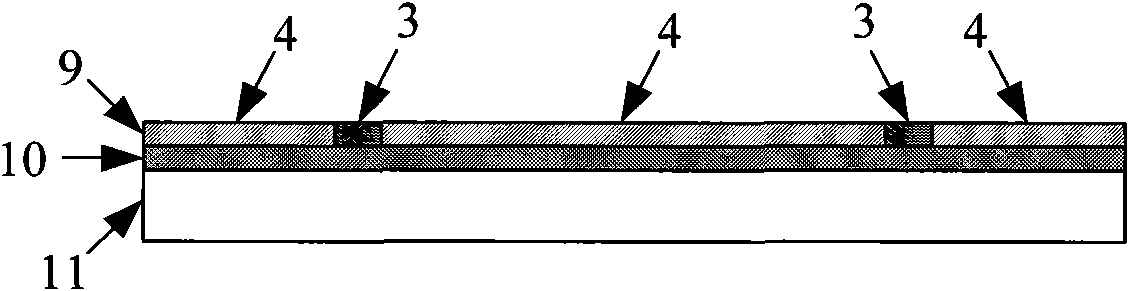

[0025] (1) On the top silicon layer of the SOI silicon wafer, a light boron doped region and a rich boron doped region are fabricated by ion implantation. Such as figure 2 As shown, in the figure, a boron-lean region 3 and a boron-rich region 4 are fabricated on the top layer silicon 9 of the SOI silicon wafer. Under the top layer of silicon 9 are buried layer silicon dioxide 10 and substrate silicon 11 .

[0026](2) Thermally oxidize the SOI silicon wafer, and thermally grow a silicon oxide layer on the top layer of silicon, and thermal oxidation will reduce the thickness of the top layer of silicon. The thermal oxidation time is controlled to reduce the top silicon thickness to the target thickness of the nanobeams. Remove the thermal oxide layer on the surface.

[0027] (3)...

Embodiment 2

[0034] FIG. 7 is a structural schematic diagram of the electrostatic drive of the nanometer-thick cantilever and the piezoresistive detection of the MIS capacitive substrate by using stepped electrodes. Fig. 7(a) is a top view, and Fig. 7(b) is a top view of the nanobeam structure after removing the stepped electrodes. The nanobeams are fabricated on N-type silicon wafers, that is, the initial doping type of the nanobeams is N-type. When the cantilever nanobeam moves up and down, the stress maximum point appears at the end point, so the force sensitive resistor is made at the end point. Due to the characteristics of the cantilever beam structure, the force sensitive resistor is arranged in a state perpendicular to the nanobeam, and the force sensitive resistor is doped with light boron. The ladder-shaped electrode and the lightly boron-doped region on the nanobeam form a MIS capacitor structure, and the densely boron-doped region on the nanobeam is used for electrostatic driv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com