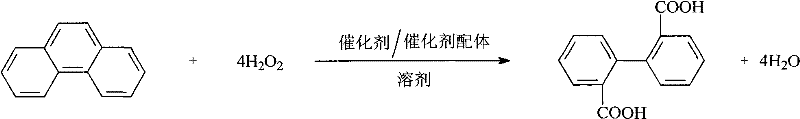

Method for preparing 2,2'-biphenyldicarboxylic acid

A biphenyl dicarboxylic acid, H2O2 technology, applied in the direction of oxidative preparation of carboxylic acid, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of post-processing burden increase, acid waste water generation, high production cost, etc. Effects of processing burden, less usage, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add industrial phenanthrene (25mmol, content 95%) in the Erlenmeyer flask that 100mL has condenser tube, mass concentration is acetic acid (8ml) of 99%, Na 2 WO 4 (0.5mmol) and sulfosalicylic acid (2mmol), be heated to 80 ℃, slowly add mass concentration under the condition of stirring and be 30% H 2 o 2 20mL, the time of adding is 1h. Continue heating, and continue to react for 3 hours at 90-100°C under reflux conditions. After the reaction, cool and filter to obtain white crystal 2,2'-biphenyldicarboxylic acid with a yield of 71%, a melting point of 226-228°C, and a purity of >99%. Product structure by IR, 1 H NMR, 13 C NMR, elemental analysis for characterization. The analysis results are as follows:

[0033] IR (KBr tablet method, cm -1 ): 2996(OH), 2885, 1689(C=O), 1597(V C=C ), 1579 (v C=C ), 1475 (V C=C ), 1455 (V C=C ), 753 (γ =CH ).

[0034] 1 H NMR (DMSO-d 6 ,300MHz)δ H : 12.43(s, 2H, 2OH), 7.90(d,

[0035] 2H, J=7.5Hz, 2ArH), 7.56(t.

[00...

Embodiment 2

[0042] Add industrial phenanthrene (25mmol, content 95%) in the Erlenmeyer flask that 100mL has condenser tube, mass concentration is acetic acid (5ml) of 99%, K 2 WO 4 (0.5mmol) and oxalic acid (2mmol), heated to 80 ° C, slowly adding mass concentration of 30% H 2 o 2 20mL, the time of adding is 1h. Continue heating, and continue to react for 6 hours at 90-100°C under reflux conditions. After the reaction, cool and filter to obtain white crystal 2,2'-biphenyldicarboxylic acid with a yield of 74%, a melting point of 226-228°C, and a purity of >99%. Product structure by IR, 1 H NMR, 13 C NMR, elemental analysis for characterization. The analysis result is consistent with Example 1.

Embodiment 3

[0044] Add industrial phenanthrene (25mmol, content 95%), mass concentration is 80% acetic acid (6ml), mass concentration is 99% propionic acid (2ml) and phosphotungstic acid (0.05 mmol), heated to 70 ° C, slowly adding mass concentration under the condition of stirring is 30% H 2 o 2 25mL, the time to add is 1.5h. Continue heating, and continue to react for 4.5h at 90-100°C under reflux conditions. After the reaction, cool and filter to obtain white crystal 2,2'-biphenyldicarboxylic acid with a yield of 63%, a melting point of 225-228°C, and a purity of >99%. Product structure by IR, 1 H NMR, 13 C NMR, elemental analysis for characterization. The analysis result is consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com