Structure of film thermoelectric converter based on bi-material microcantilevel and fabricating method thereof

A micro-cantilever beam, dual-material technology, applied in the structure and manufacture of thermoelectric converters, and the structure and manufacture of thin-film thermoelectric converters, can solve large conversion errors, reduce thermal conductivity and resistivity, and reduce heating resistance temperature. and other problems, to achieve the effect of high sensitivity, flexible design, and small AC-DC conversion error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

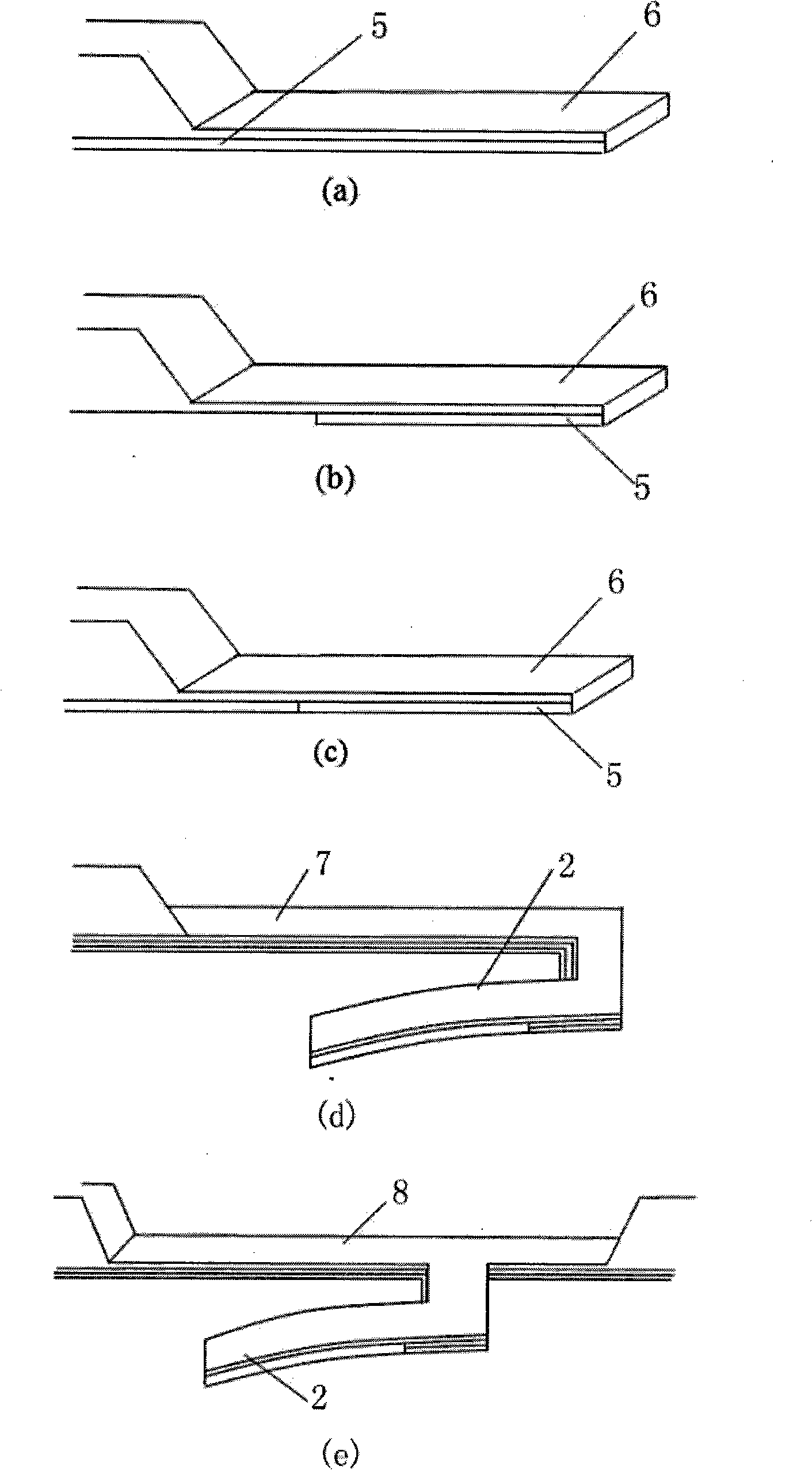

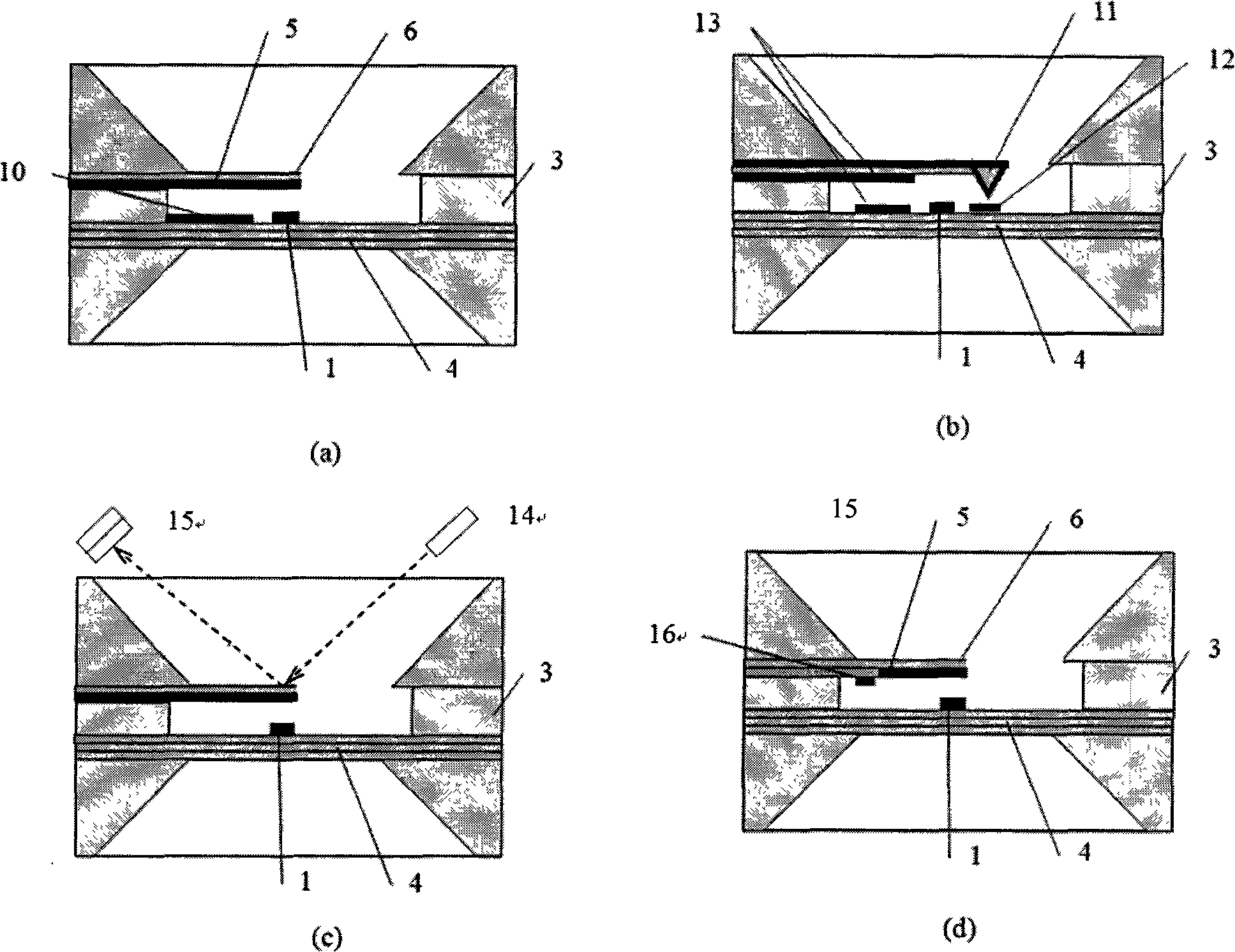

[0045] The technical scheme of the invention is used to manufacture a thin-film thermoelectric transducer for detecting the deformation of a double-material micro-cantilever beam by a piezoresistive method. Among them, the dual-material microcantilever 2 adopts figure 1 (c) Bimaterial cantilever beam shown. Its production process is as follows:

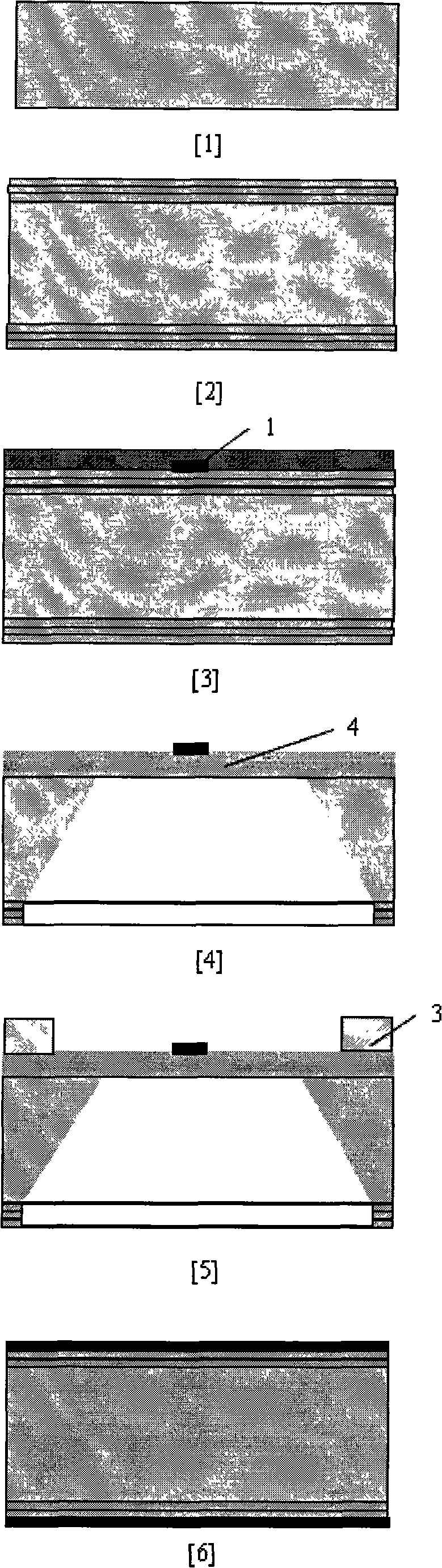

[0046] 1) The original silicon wafer is an N-type, (100) plane silicon wafer with a resistivity of 1-10Ω.cm. (see attached image 3 [1])

[0047] 2) Low-pressure chemical vapor deposition (LPCVD) silicon nitride film with a thickness of 200nm; low-pressure chemical vapor deposition of polysilicon film with a thickness of 200nm, and thermal oxidation to convert it into a silicon dioxide film; low-pressure chemical vapor deposition of silicon nitride film , thickness 200nm. (see attached image 3 [2])

[0048] 3) Obtain the heating resistor 1 pattern by photolithography, sputter the nickel-chromium alloy thin film, and make the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com