Pellicle and method for fabrication thereof

一种防护薄膜、制造方法的技术,应用在图纹面的照相制版工艺、用于光机械处理的原件、照相制版工艺曝光装置等方向,能够解决硅结晶膜龟裂、制造良品率降低等问题,达到制造良品率高、性质稳定、降低龟裂或孔隙的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

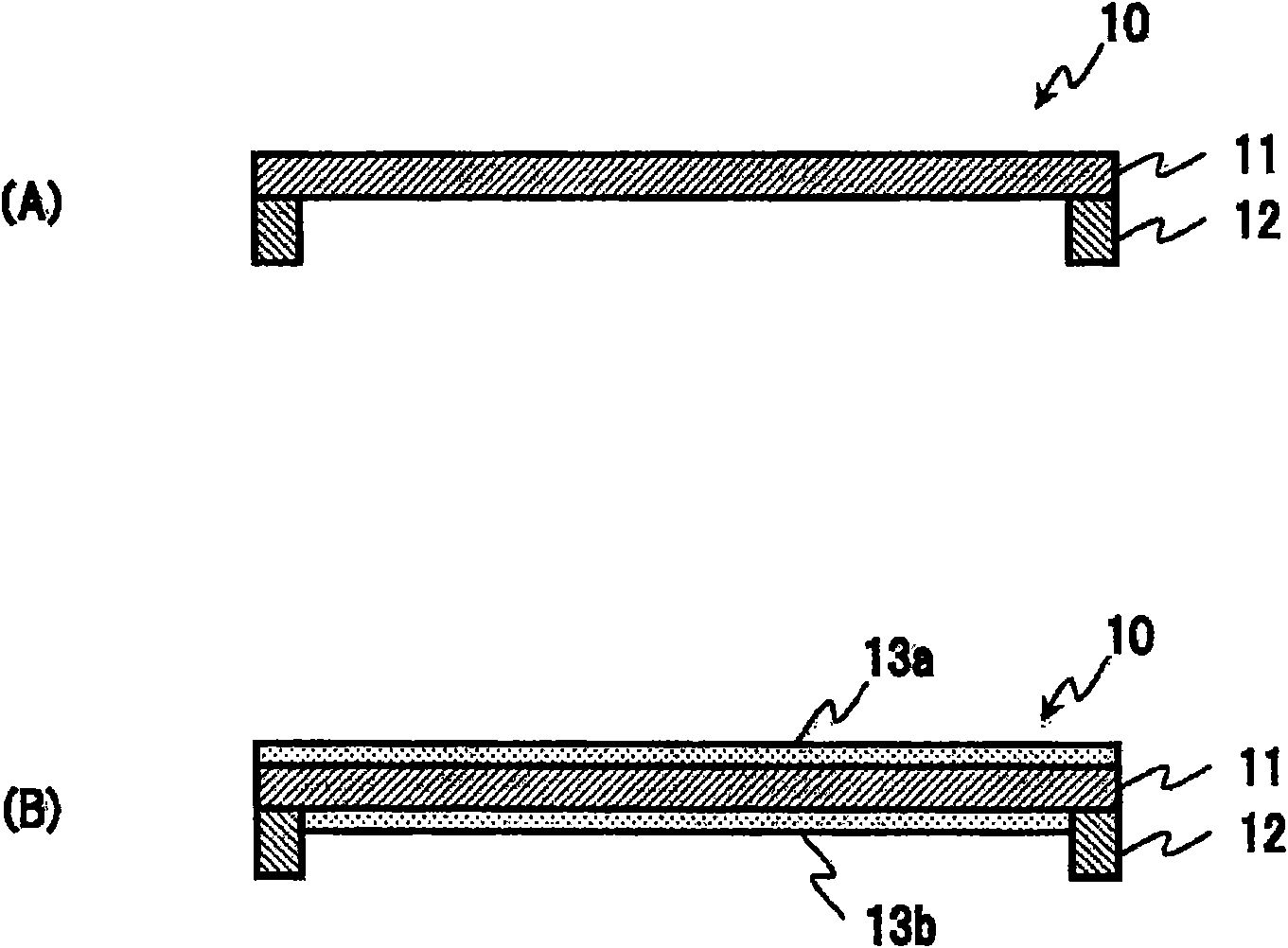

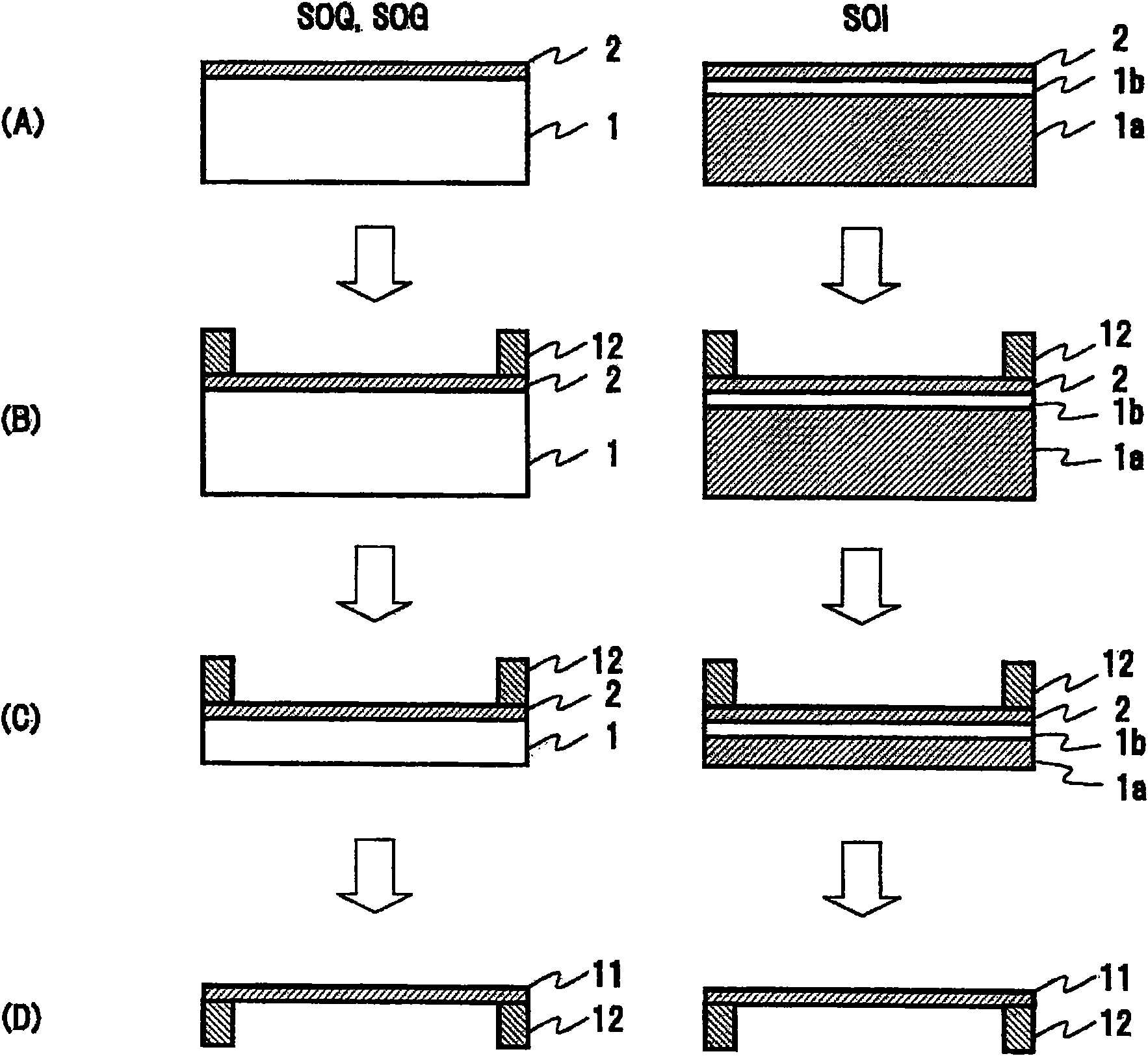

[0057] figure 2 It is an explanatory diagram of the manufacturing process, which is used to illustrate the manufacturing method of the pellicle module of the present invention. SOI substrates in a broad sense include SOQ (Silicon On Quartz) substrates and SOG (Silicon On Glass) substrates, and the support substrate 1 at this time is a quartz substrate and a glass substrate, respectively. Also, the support substrate 1 of an SOI (Silicon On Insulator) substrate in a narrow sense is a substrate on which an oxide film 1b is provided on the surface of a silicon substrate 1a. On the main surfaces of these supporting substrates, a silicon single crystal film 2 having a crystal plane inclined by 3 to 5° from a lattice plane belonging to the {111} plane group as the main surface is provided, and the silicon single crystal film 2 serves as a protective film. . In addition, the silicon single crystal film 2 provided on the supporting substrate has an absorption coefficient of EUV ligh...

Embodiment 2

[0066] according to figure 2In the steps shown, a pellicle assembly in which the pellicle 11 is supported by the pellicle frame 12 is produced, the pellicle 11 is made of a silicon single crystal film, and the silicon single crystal film has a crystallographic orientation for the to direction The azimuth plane with an inclination of 3-5° (3°off to 5°off) is used as the main surface. Also, the thickness of the pellicle film 11 of the silicon single crystal film of this embodiment is 20 nm. Then, on the surface and the bottom surface of the protective film 11 respectively, a SiC thin film with a thickness of several nm is vapor-deposited on the protective film 11 of the silicon single crystal film by gas cluster ion beam evaporation method, so as to coat the protective film. 11.

[0067] For the pellicle modules obtained in Examples 1 and 2, the transmittance of EUV light is above 50%, the processing capacity per unit time during EUV exposure can also reach a practical leve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorptance | aaaaa | aaaaa |

| absorptance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com