Method for preparing lithium iron phosphate material and cladding the material with carbon

A technology of lithium iron phosphate and material package, which is applied in the direction of electrode manufacturing, etc., to achieve the effect of excellent material performance, small internal resistance and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

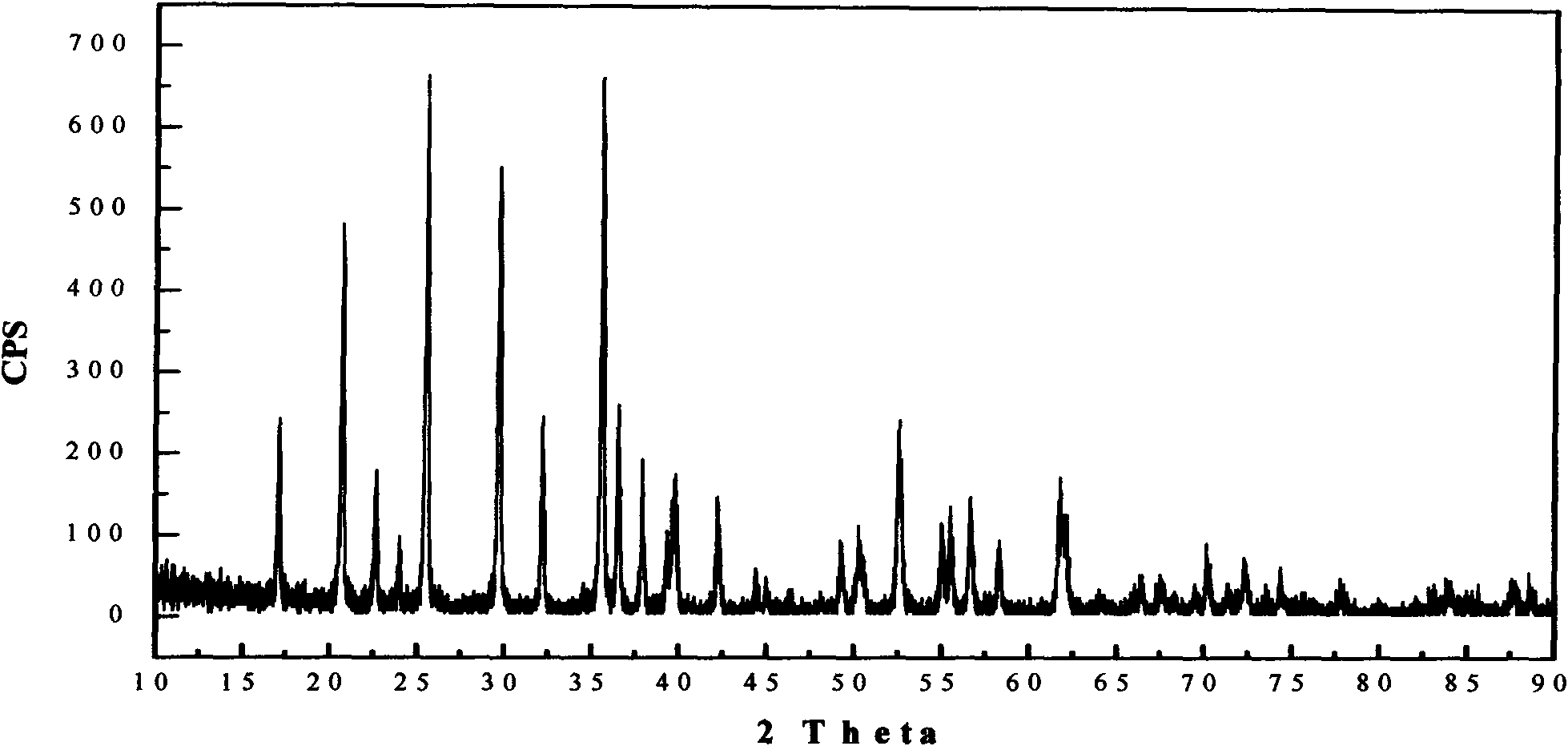

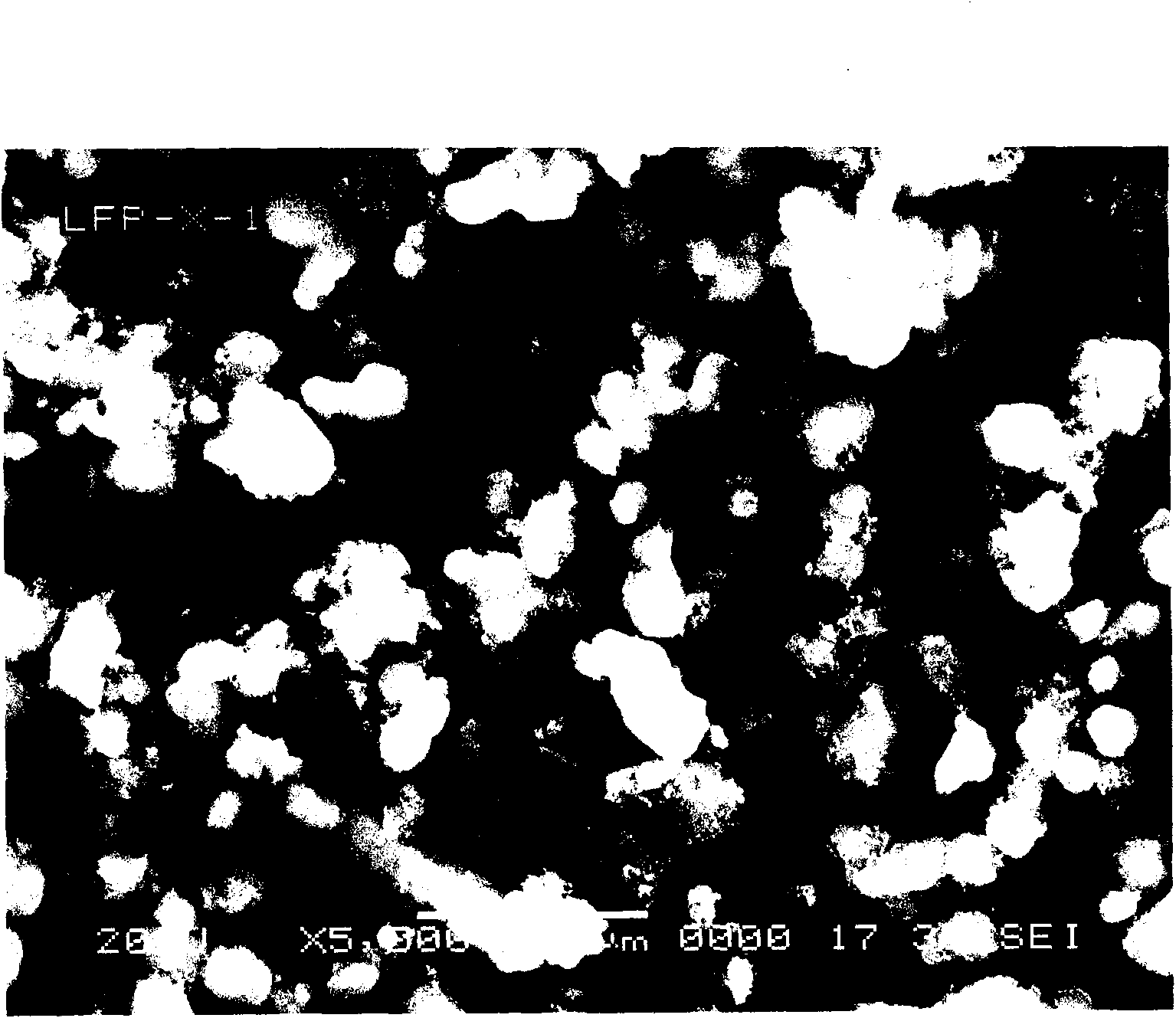

[0017] with Fe 2 o 3 , LiH 2 PO 4 As the main raw material, with MgO as the dopant, according to LiFe 0.98 Mg 0.02 PO 4 Ratio batching, the raw material is 500kg altogether. Add acetone as a dispersant, stir and ball mill for 2 hours, and dry in vacuum. It is continuously fed into the furnace from the furnace head of the rotary kiln. From the tail end of the rotary kiln, high-purity nitrogen with 10% acetylene is injected at a distance of 5m 3 The flow rate of / h is passed into the furnace and sintered at 655°C. The material starts to discharge continuously after sintering in the rotary kiln for 2 hours. The carbon-coated lithium iron phosphate cathode material is obtained after being cooled by a rotary cooling discharger, crushed and classified. figure 1 is the X-ray diffraction pattern of the product. figure 2 It is a scanning electron microscope photo of a carbon-coated lithium iron phosphate material product. Ultrafine nano-sized carbon particles are effective...

Embodiment 2

[0019] FePO 4 2H 2 O. Li 2 CO 3 As the main raw material, the raw material is 1000kg in total. Add acetone as a dispersant, stir ball mill for 4 hours, and vacuum dry. It is continuously fed into the furnace from the furnace head of the rotary kiln. High-purity nitrogen passes through a washing bottle filled with acetone and placed in a constant temperature water bath at 52°C to obtain a mixed gas of acetone and nitrogen. 3 The flow rate of / h is passed into the furnace from the tail end of the rotary kiln. Sintered at 655°C. The material starts to discharge continuously after sintering in the rotary kiln for 2 hours. The carbon-coated lithium iron phosphate cathode material is obtained after being cooled by a rotary cooling discharger, crushed and classified.

Embodiment 3

[0021] with Fe 2 o 3 , LiH 2 PO 4 As the main raw material, Mg(OH) 2 as a dopant, according to LiFe 0.98 Mg 0.02 PO 4 Ratio batching, the raw material is 500kg altogether. Add acetone as a dispersant, stir and ball mill for 2 hours, and dry in vacuum. Continuously feed into the furnace from the furnace head of the rotary kiln. High-purity nitrogen passes through a generation tube equipped with naphthalene and placed at a constant temperature of 175°C to obtain a mixed gas of naphthalene vapor and nitrogen. 3 The flow rate of / h is passed into the furnace from the tail end of the rotary kiln. Sintered at 655°C. The material starts to discharge continuously after sintering in the rotary kiln for 2 hours. The carbon-coated lithium iron phosphate cathode material is obtained after being cooled by a rotary cooling discharger, crushed and classified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com