Preparation method of ketorolac tromethamine

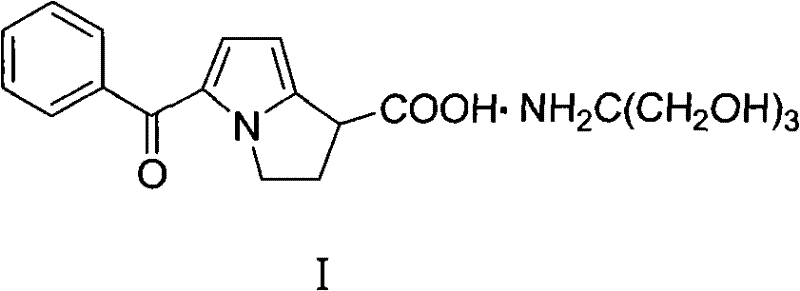

The technology of ketorolac tromethamine and tromethamine is applied in the field of preparation of anti-inflammatory and analgesic ketorolac tromethamine, and can solve the problems of long hydrolysis reaction time, ketorolac tromethamine content, color To solve problems such as poor degree of reaction, to achieve the effect of short reaction time, improved reaction yield, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

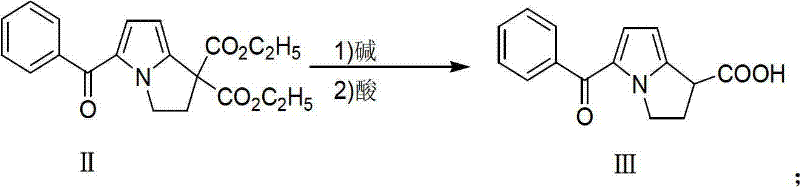

[0032] The synthesis of embodiment 1 ketorolac

[0033] In a 500mL three-neck round bottom flask, add compound II (142g, 0.4mol), 95% ethanol (100ml), 10% aqueous sodium hydroxide solution (50ml), heat to 70°C and stir for 2h, TLC (ethyl acetate Esters: Petroleum ether=1: 2) detect that the reaction is complete, evaporate the ethanol under reduced pressure, adjust the pH to 2 with concentrated hydrochloric acid in the -5°C water layer, and precipitate a solid, and obtain khaki solid 101.9g by suction filtration, and use methanol: water=3 : 1 (volume ratio) to obtain 96.8 g of white solid compound III with a yield of 95%.

Embodiment 2

[0034] The synthesis of embodiment 2 ketorolac

[0035] In a 500mL three-neck round bottom flask, add compound II (142g, 0.4mol), methanol (110ml), 10% potassium hydroxide aqueous solution (55ml), heat to 60°C and stir for 4h, TLC detects ethyl acetate:petroleum Ether=1:2 (volume ratio) The reaction is complete. The methanol was distilled off under reduced pressure, and the pH of the -10°C water layer was adjusted to 2.5 with 3mol / L sulfuric acid, and a solid was precipitated, which was filtered with suction to obtain 95.8 g of a khaki solid, which was refined with methanol:water=1:1 (volume ratio) to obtain a white solid 88.8 g g, yield 87%.

Embodiment 3

[0036] The synthesis of embodiment 3 ketorolac

[0037] In a 500mL three-neck round bottom flask, add compound II (142g, 0.4mol), 95% ethanol (120ml), 10% aqueous sodium hydroxide solution (60ml), heat to 50°C and stir for 4.5h, TLC detects acetic acid Ethyl:petroleum ether=1:2 (volume ratio) The reaction is completed, and the ethanol is evaporated under reduced pressure, and the pH of the 10°C water layer is adjusted to 2 with concentrated hydrochloric acid, and the solid is precipitated, and the khaki solid 103.4g is obtained by suction filtration. = 3:1 (volume ratio) Purified to obtain 97.9 g of white solid compound III with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com