Process technology for non-caking coal or weak caking coal

A technology of weak caking coal and processing technology, applied in the field of coal chemical industry, to achieve the effect of improving utilization rate, improving raw material utilization rate and protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

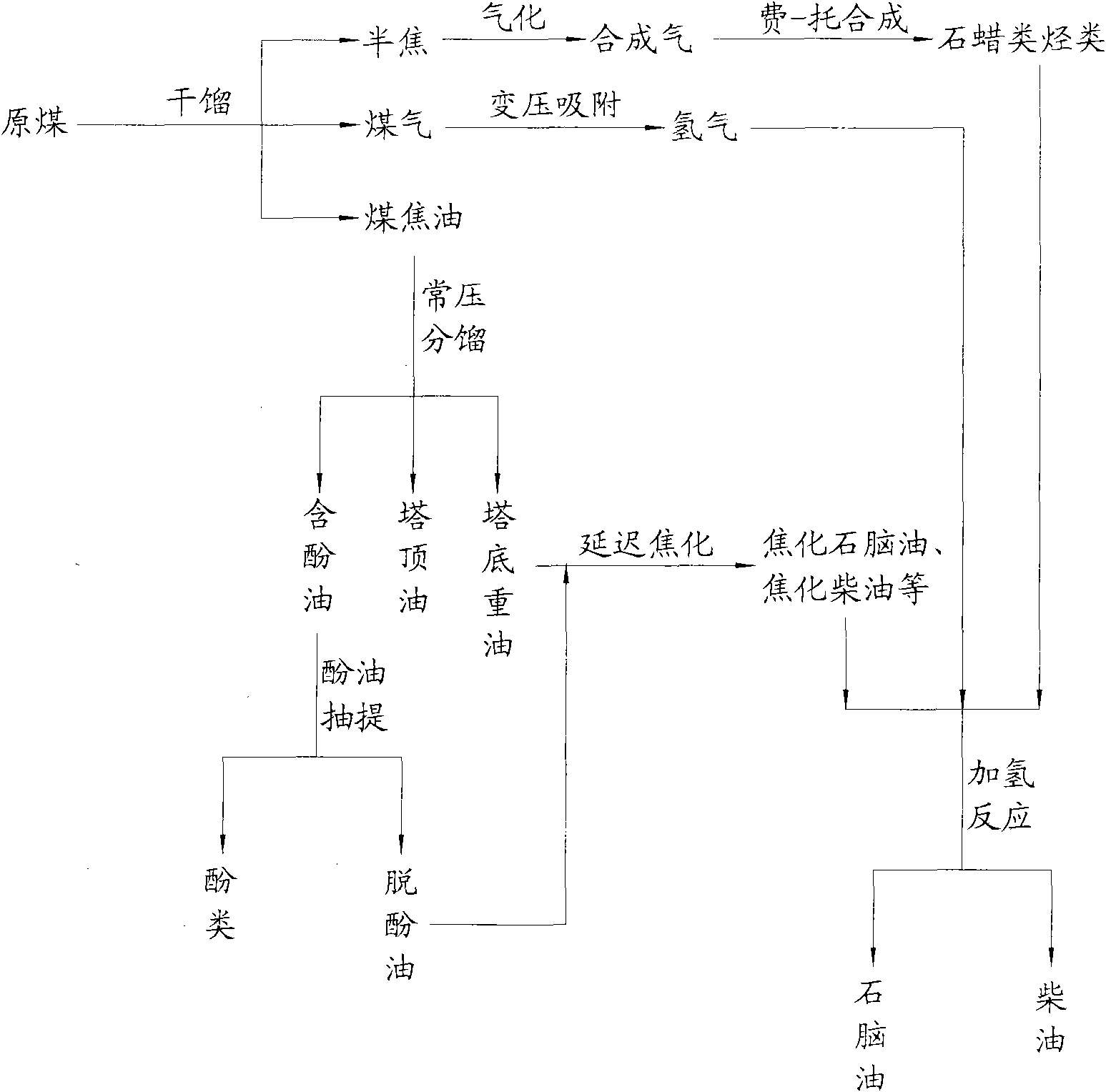

Method used

Image

Examples

Embodiment 1

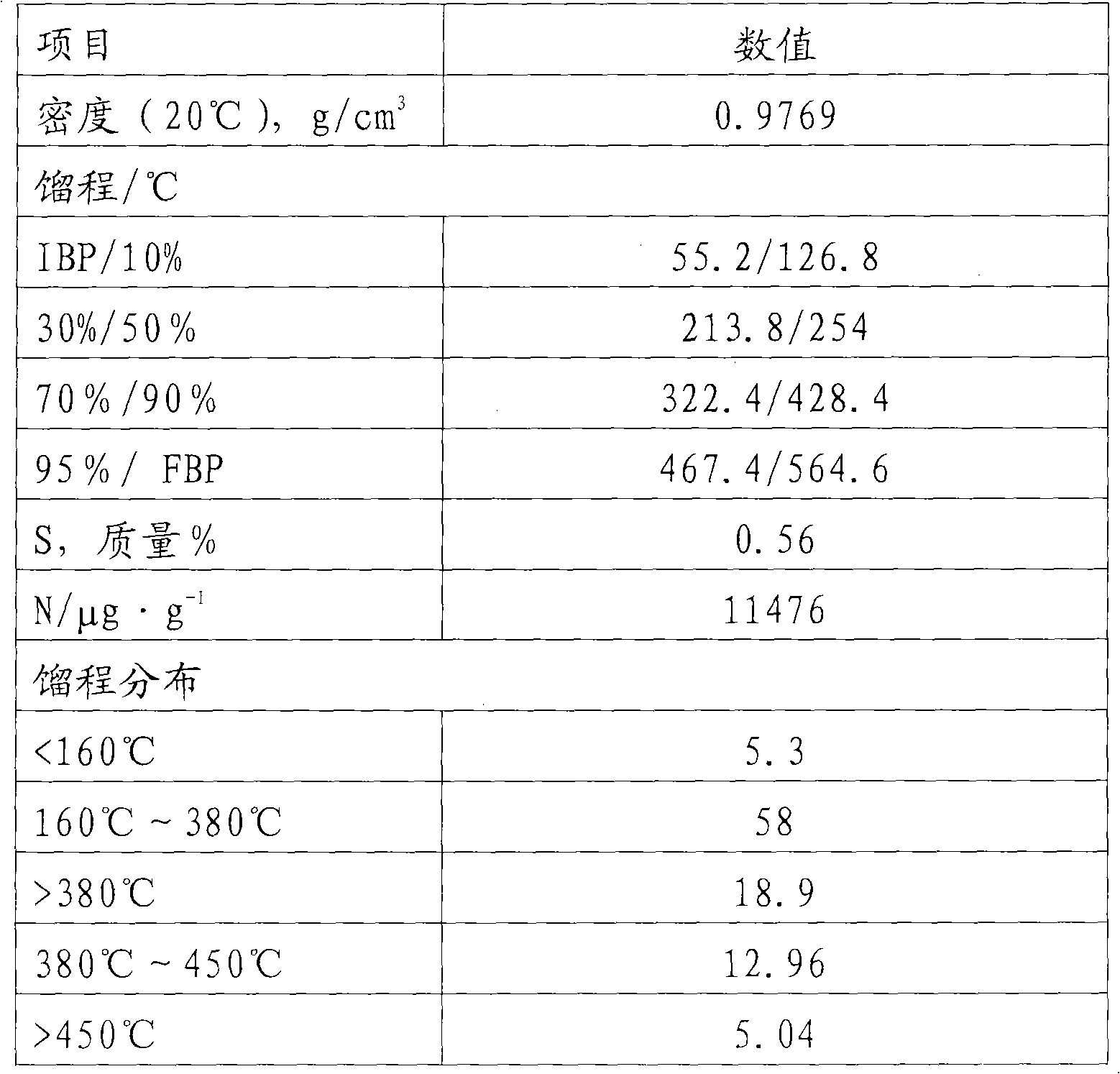

[0069] The Nanning lignite is sent to a fluidized bed dry distillation reactor for dry distillation reaction at a pressure of 0.1 MPa and an operating temperature of 500° C. to produce coal gas, coal tar and semi-coke. The properties of coal tar are shown in Table 1. After purification, the coal gas enters the pressure swing adsorption device, passes through the adsorption bed composed of zeolite molecular sieve, etc., and the operating pressure is 2MPa. The hydrogen in it is extracted, and the carbon monoxide component is also produced by reacting with water by the medium-shift technology. In addition to hydrogen, the pressure swing adsorption technology is used together with the hydrogen produced by coal retort to propose the feed for the coal tar hydrocracking unit. The semi-coke is sent to the fluidized bed coal gas generator, where it reacts with oxygen and water vapor to produce syngas and coal ash. During the gasification of semi-coke, the semi-coke reacts with oxygen and wat...

Embodiment 2

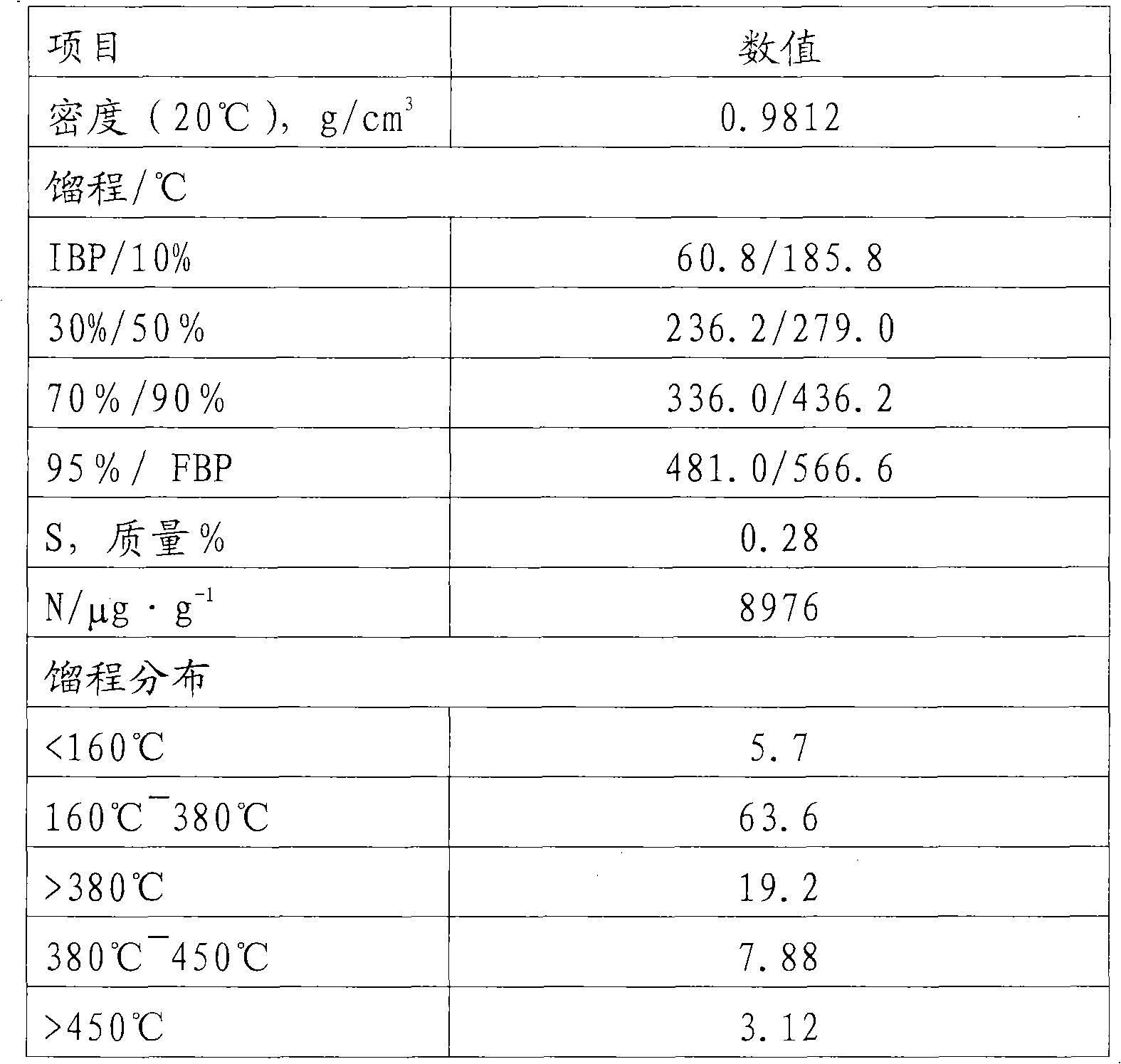

[0073] The ylang coal is sent to a medium fluidized bed dry distillation reactor for dry distillation reaction, the pressure is 0.12MPa, the operating temperature is 600°C, and coal gas, coal tar and semi-coke are generated. The properties of coal tar are shown in Table 2. After the dry distillation gas is purified, it enters the pressure swing adsorption device, passes through the adsorption bed composed of silica gel, etc., the operating pressure is 2.45MPa, and the hydrogen in it is extracted, and the carbon monoxide component in it is also reacted with water by the medium change technology. Hydrogen is generated, and the pressure swing adsorption technology is used together with the hydrogen produced by coal retorting to propose the feed for the coal tar hydrogenation unit. The semi-coke is sent to the fluidized bed coal gas generator, where it reacts with oxygen and water vapor to produce syngas and coal ash. During semi-coke gasification, semi-coke reacts with oxygen and wat...

Embodiment 3

[0077] The ylang-ylang lignite is fed into a fluidized bed dry distillation reactor for dry distillation at a pressure of 0.18MPa and an operating temperature of 650°C to generate dry distillation gas, coal tar and semi-coke. The properties of dry distillation coal tar are shown in Table 3. After the dry distillation gas is purified, it enters the pressure swing adsorption device, passes through an adsorption bed composed of carbon monoxide adsorbent, etc., with an operating pressure of 1.2MPa, and the hydrogen in it is extracted for the feed of the coal tar hydrogenation device. The semi-coke is sent to the fluidized bed coal gas generator, where it reacts with oxygen and water vapor to produce syngas and coal ash. During the gasification of semi-coke, the semi-coke reacts with oxygen and water vapor (the volume ratio of water vapor and oxygen is 5:1) to produce synthesis gas (carbon monoxide and hydrogen) and coal ash; the reaction pressure of the gas generator is 1.6MPa, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com