Separation method of lysine bacteria

A separation method, lysine technology, applied to the separation of microorganisms, etc., can solve the problems of large equipment investment and high process energy consumption, and achieve the effect of high equipment investment, low equipment investment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

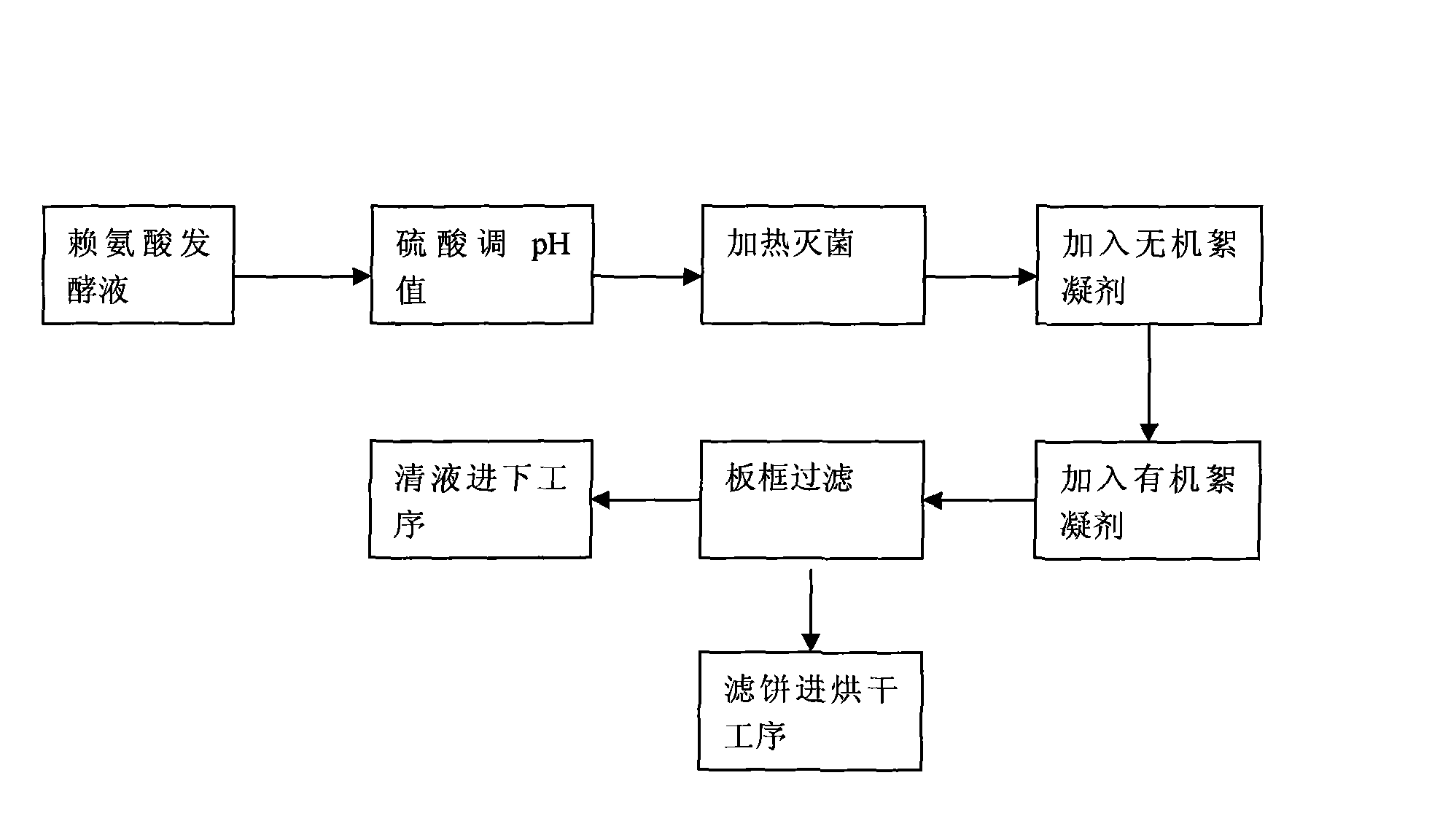

Method used

Image

Examples

Embodiment 1

[0022] 1. Materials and equipment:

[0023] Equipment and material name

model

quantity

Remark

Flow 100L

1 set

Inorganic flocculant

500g

organic flocculant

Anionic

500g

Molecular weight 10 million polypropylene

Amide resin

Lysine Fermentation Broth

-----

250L

Workshop offers concentration 15%

concentrated sulfuric acid

industrial grade

5kg

Workshop offers

Plate and frame filter press

---

1 set

Filtration area 0.25 square meters

[0024] 2. Specific methods and results:

[0025] 2.1 Put 250L of fermentation broth into the reaction tank, adjust the pH value to 3.7 with concentrated sulfuric acid, heat and sterilize, the sterilization condition is 70°C and keep it warm for 1.5 hours;

[0026] 2.2 Prepare the inorganic flocculant with water to make a solution with a concentration o...

Embodiment 2

[0035] 1. Materials and equipment:

[0036] Equipment and material name

model

quantity

Remark

Flow 100L

1 set

Inorganic flocculant

PAC

500g

organic flocculant

Anionic

500g

Polyacrylamide with a molecular weight of 5 million

Amine resin

Lysine Fermentation Broth

-----

250L

Workshop offers

Concentration 14.1%

concentrated sulfuric acid

industrial grade

4kg

workshop offers

Plate and frame filter press

---

one

Filtration area 0.25 square meters

[0037] 2. Specific methods and results:

[0038] 2.1 Put 250L of fermentation broth into the reaction tank, adjust the pH value to 4.8 with concentrated sulfuric acid, heat and sterilize, the sterilization condition is 65°C and keep it warm for 2.5 hours;

[0039] 2.2 Prepare the inorganic flocculant with water to make a solution with a concentr...

Embodiment 3

[0048] 1. Materials and equipment:

[0049] Equipment and material name

model

quantity

Remark

Flow 100L

1 set

Inorganic flocculant

PAC

500g

organic flocculant

Anionic

500g

Molecular weight 15 million polypropylene

Amide resin

Lysine Fermentation Broth

-----

250L

Workshop offers

Concentration 13.5%

concentrated sulfuric acid

industrial grade

Workshop offers

Plate and frame filter press

---

1 set

Filtration area 0.25 square meters

[0050] 2. Specific methods and results:

[0051] 2.1 Put 250L of fermentation broth into the reaction tank, adjust the pH value to 5.6 with concentrated sulfuric acid, heat and sterilize, the sterilization condition is 70°C and keep it warm for 2 hours;

[0052] 2.2 Prepare the inorganic flocculant with water to make a solution with a concentration of 2%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com