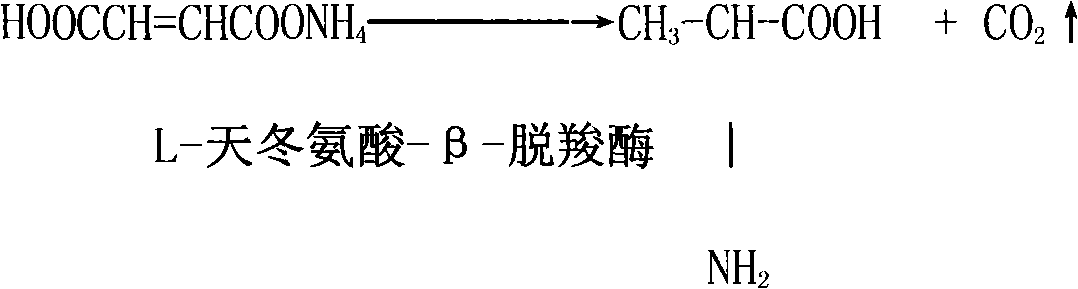

Method for producing optically pure L-alanine by one pseudomonas and two enzymes

An alanine and optical technology, applied in the field of enzymatic production of L-alanine, can solve the problems of high cost, many production links, low optical purity of products, etc., achieve high yield, reduce environmental pollution, and reduce production The effect of link and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Prepare seed solution 1000ml, seed solution proportioning (mass percentage, hereinafter the same): 1.0% fumaric acid, 1.0% peptone, 0.8% corn steep liquor, 0.02% magnesium sulfate, 0.01% potassium dihydrogen phosphate, and the balance is purified water, Adjust the pH to 7.0 with ammonia water. Pack in five 1000ml Erlenmeyer flasks after sterilization, inoculate the inclined surface at 30°C, incubate on a shaking table for 15 hours at a rotating speed of 90r / min, inoculate 100L of fermentation broth, the ratio of fermentation broth is 2.0% sodium glutamate, 1.0% peptone , 0.8% of corn steep liquor, 0.02% of magnesium sulfate, 0.01% of potassium dihydrogen phosphate, the balance is pure water, and the pH value is adjusted to 7.0 with ammonia water. Fermentation culture conditions: culture temperature 29±2°C, ventilation ratio 1:2, tank pressure 0.05MPa, culture for 26 hours. Take the fermentation broth to prepare 500L conversion liquid, add 25g ammonium fumarate, the conv...

Embodiment 2

[0043] Mix 2000ml of seed solution, the ratio of seed solution is 1.2% fumaric acid, 1.1% peptone, 0.9% corn steep liquor, 0.03% magnesium sulfate, 0.02% potassium dihydrogen phosphate, the balance is pure water, adjust the pH value to 7.0 with ammonia water . Pack in 10 1000ml Erlenmeyer flasks after sterilization, inoculate the inclined surface at 30°C, incubate on a shaking table for 18 hours, the rotating speed of the shaking table is 100r / min, inoculate 100L fermentation broth, the ratio of fermentation broth is 2.2% sodium glutamate, 1.1% peptone , 0.9% of corn steep liquor, 0.03% of magnesium sulfate, 0.02% of potassium dihydrogen phosphate, and the balance is pure water, and the pH value is adjusted to 7.0 with ammonia water. Fermentation culture conditions: culture temperature 29±2°C, ventilation ratio 1:2, tank pressure 0.05MPa, culture for 28 hours. Take the fermentation broth to prepare 500L transformation liquid, add 25g ammonium fumarate, the transformation temp...

Embodiment 3

[0045] Mix 800ml of seed solution, the ratio of seed solution is 0.8% fumaric acid, 0.8% peptone, 0.6% corn steep liquor, 0.01% magnesium sulfate, 0.01% potassium dihydrogen phosphate, the balance is pure water, adjust the pH value to 7.0 with ammonia water . Divide into four 1000ml Erlenmeyer flasks after sterilization, inoculate the slope at 30°C, incubate on a shaking table for 14 hours at a speed of 110r / min, inoculate 100L of fermentation broth, the ratio of fermentation broth is 1.8% sodium glutamate, 0.9% peptone , 0.6% of corn steep liquor, 0.01% of magnesium sulfate, 0.01% of potassium dihydrogen phosphate, and the balance is pure water, and the pH value is adjusted to 7.0 with ammonia water. Fermentation culture conditions: culture temperature 29±2°C, ventilation ratio 1:3, tank pressure 0.05MPa, culture 20h. Take the fermentation broth to prepare 500L of transformation liquid, add 25g of ammonium fumarate, the transformation temperature is 45°C, and the transformat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com