Cefazedone sodium medicament powder injection and method for synthesizing raw medicine of Cefazedone sodium

A technology of cefoxidone sodium and fooxidone sodium powder, which is applied in the directions of pharmaceutical formulations, antibacterial drugs, powder delivery, etc., can solve the problems of unsuitability for industrialized large-scale production, low cefoxidone yield, shortened synthesis route, etc. problem, to achieve the effect of easy control, simplified purification process and short synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

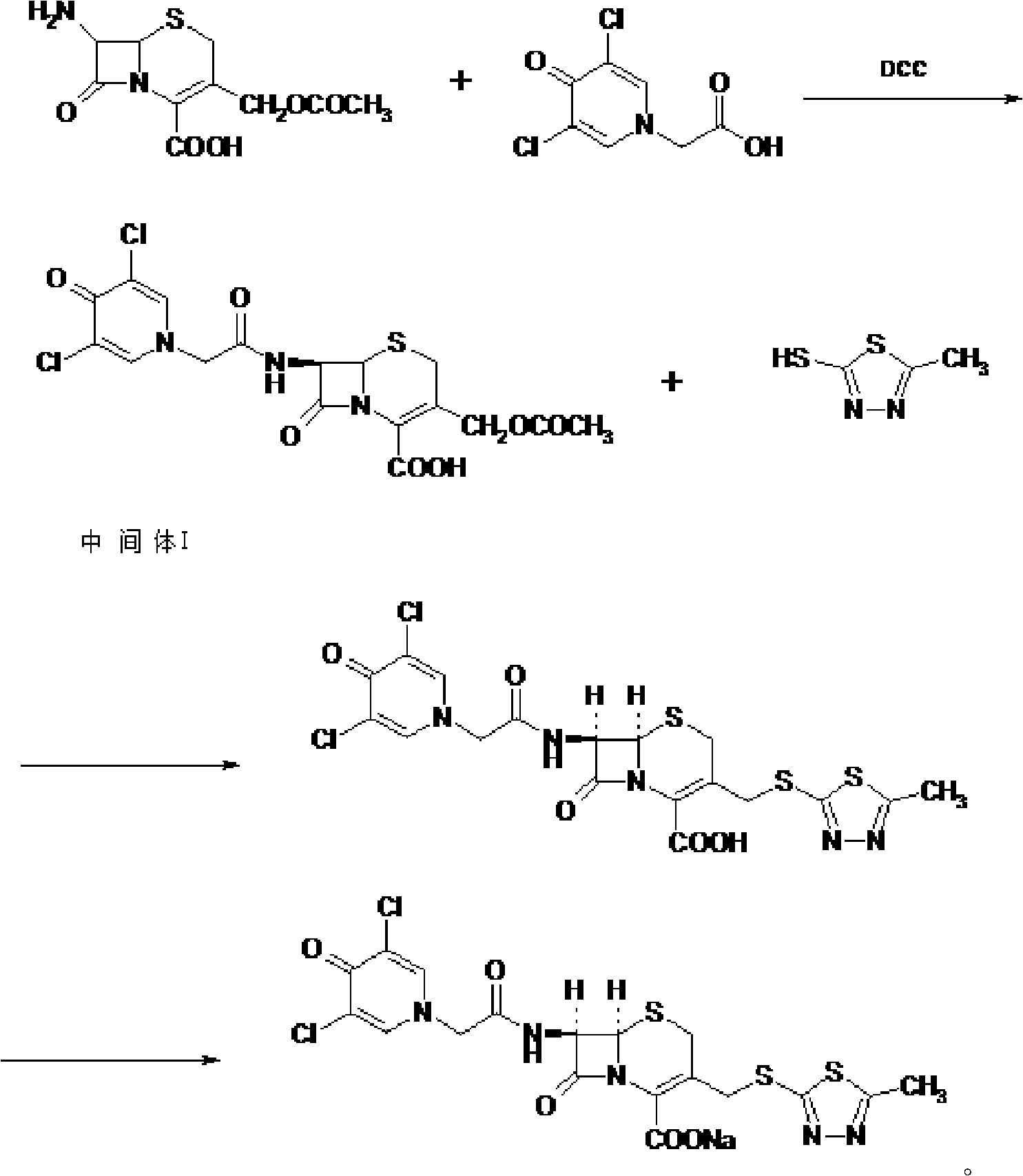

[0054] Synthesis of Intermediate I:

[0055] Put 20g (0.0735mol) of 7-ACA into the flask, add 200ml of tetrahydrofuran, 7.5g of triethylamine, add 17.2g (0.085mol) of dicyclohexylcarbodiimide (DCC), and add dichloromethane / DMF= 1 / 1 (v / v) solution 200ml, cool down to 0°C in an ice bath, add 17.6g (0.0793mol) of 3,5-dichloropyridoneacetic acid, and add 3,5-dichloropyridoneacetic acid per minute After adding 1 / 20 of the total amount, the reaction was stirred at 20°C for 0.5 hour. After filtration, the filtrate was evaporated to dryness under reduced pressure at 50°C, recrystallized from diethyl ether, refrigerated for crystallization for more than 8 hours, filtered, and vacuum-dried at 50°C to obtain 33.1 g of intermediate I, with a yield of 94.5%. The infrared characteristic absorption peak that obtains intermediate I is: 3400cm -1 , 1654.48cm -1 , 1600cm -1 , 1400cm -1 .

Embodiment 2

[0057] Synthesis of Intermediate I:

[0058] Put 20g (0.0735mol) of 7-ACA into the flask, add 200ml of dichloromethane, 7.5g of triethylamine, add 19.68g (0.0955mol) of dicyclohexylcarbodiimide (DCC), and add dichloromethane solution 200ml, cool down to -5°C in an ice bath, add 19.6g (0.0882mol) of 3,5-dichloropyridoneacetic acid, and add 1 / 10 of the total amount of 3,5-dichloropyridoneacetic acid per minute. , and stirred at 25°C for 0.5 hours. After filtration, the filtrate was evaporated to dryness under reduced pressure at 50°C, recrystallized from diethyl ether, refrigerated for crystallization for more than 8 hours, filtered, and vacuum-dried at 50°C to obtain 33.7g of intermediate I, with a yield of 96.4%. The infrared characteristic absorption peak that obtains intermediate I is: 3400cm -1 , 1654.48cm -1 , 1600cm -1 , 1400cm -1 .

Embodiment 3

[0060] Synthesis of Intermediate I:

[0061] Put 20g (0.0735mol) of 7-ACA into the flask, add 200ml of N,N-dimethylformamide, 7.5g of triethylamine, and 15.2g (0.0735mol) of dicyclohexylcarbodiimide (DCC), Add 200ml of dichloromethane / DMF=1 / 1 (v / v) solution, cool down to 0°C in an ice bath, add 24.47g (0.11mol) of 3,5-dichloropyridoneacetic acid, and add 3 , 1 / 15 of the total amount of 5-dichloropyridoneacetic acid was added, and the reaction was stirred at 35° C. for 0.5 hours. After filtration, the filtrate was evaporated to dryness under reduced pressure at 50°C, recrystallized from diethyl ether, refrigerated for crystallization for more than 8 hours, filtered, and vacuum-dried at 50°C to obtain 31.7g of intermediate I, with a yield of 90.6%. The infrared characteristic absorption peak that obtains intermediate I is: 3400cm -1 , 1654.48cm -1 , 1600cm -1 , 1400cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com