Triazine carbonific containing aromatic chain structure and preparation method

A technology of triazine carbon-forming agent and chain structure, which is applied to fire-resistant coatings and other directions, can solve the problems of large amount of organic solvent, complicated preparation process, difficult post-processing, etc., and achieves short reaction time, simple preparation process and simple post-processing method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

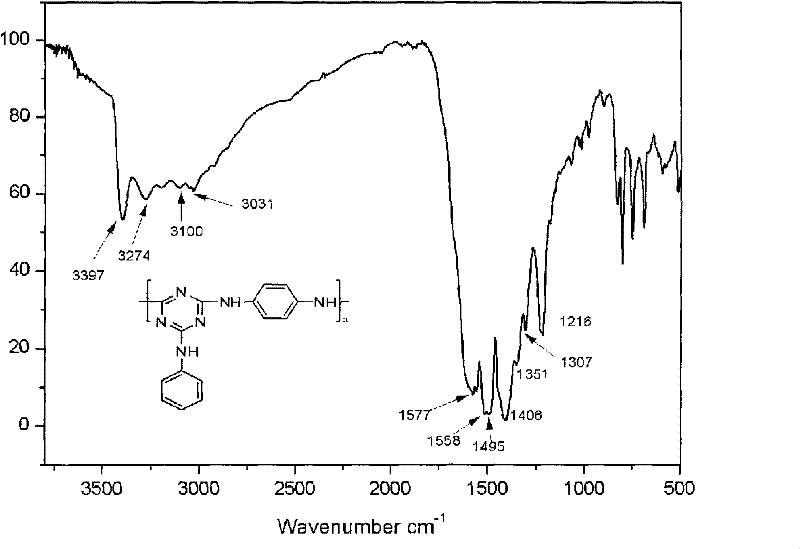

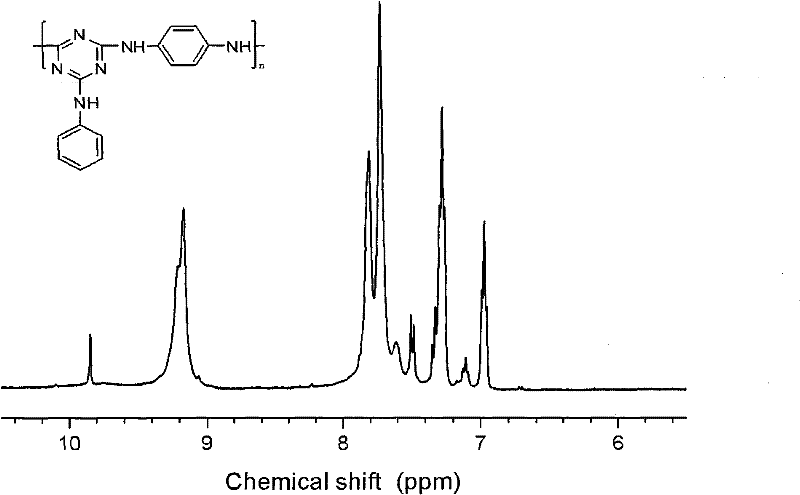

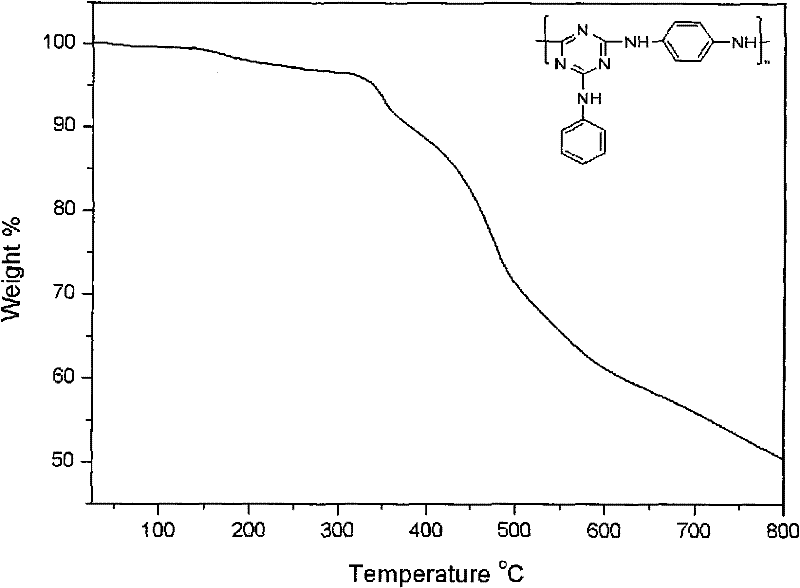

[0029] Embodiment 1: Under the protection of high-purity nitrogen, 1.84g cyanuric chloride is put into the reactor, adds 50ml N in the reaction vessel, N-dimethylacetamide, stirs 10-30 minute and makes cyanuric chloride The cyanide is evenly dispersed. Add 1.90ml N,N-diisopropylethylamine and 0.95ml aniline at 0-20℃. After reacting for 4 hours, add 1.90ml N,N-diisopropylethylamine to the reaction vessel successively. Ethylamine and 0.54 g p-phenylenediamine. Raise the reaction temperature to 45° C., stir and react for 4 hours, then add 1.90 ml of N,N-diisopropylethylamine and 0.54 g of p-phenylenediamine to the mixed solution in sequence. Raise the reaction temperature to 110°C, stir and react for 8-10 hours, then stop the reaction, cool, precipitate the product with water, filter with suction, wash with a large amount of water, dry in vacuum at 80°C for 48 hours, and obtain a three-dimensional aromatic chain structure Oxyzine macromolecule flame retardant. The yield is abov...

Embodiment 2

[0033] Embodiment 2: Under the protection of high-purity nitrogen, 1.84g cyanuric chloride is put into the reactor, and 50ml N, N-dimethylacetamide is added in the reaction vessel, and stirred for 10-30 minutes to make the cyanuric chloride The cyanide is evenly dispersed. Add 1.90ml N,N-diisopropylethylamine and 0.95ml aniline at 0-20℃. After reacting for 4 hours, add 1.90ml N,N-diisopropylethylamine to the reaction vessel successively. Ethylamine and 0.99 g of diaminodiphenylmethane. Raise the reaction temperature to 45° C., stir and react for 4 hours, then add 1.90 ml of N,N-diisopropylethylamine and 0.99 g of diaminodiphenylmethane to the mixed solution in sequence. Raise the reaction temperature to 110°C, stir and react for 8-10 hours, then stop the reaction, cool, precipitate the product with water, filter with suction, wash with a large amount of water, dry in vacuum at 80°C for 48 hours, and obtain a three-dimensional aromatic chain structure The oxazine macromolecule...

Embodiment 3

[0034] Embodiment 3: under the protection of high-purity nitrogen, put 1.84g cyanuric chloride into the reactor, add 50ml N in the reaction vessel, N-dimethylacetamide, stir 10-30 minute to make cyanuric chloride The cyanide is evenly dispersed. Add 1.38g of anhydrous potassium carbonate and 1.01g of diaminodiphenyl ether at 0-10°C. After reacting for 4 hours, add 1.38g of anhydrous potassium carbonate and 1.00g of diaminodiphenyl ether to the reaction vessel in turn. phenyl ether. Raise the reaction temperature to 55° C., stir and react for 4 hours, then add 1.38 g of anhydrous potassium carbonate and 1.00 g of diaminodiphenyl ether to the mixed solution in sequence. Raise the reaction temperature to 110°C, stir and react for 8-10 hours, then stop the reaction, cool, precipitate the product with water, filter with suction, wash with a large amount of water, dry in vacuum at 80°C for 48 hours, and obtain a three-dimensional aromatic chain structure The oxazine macromolecule f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com