Ferrocene-porous metal-organic framework compound composite material, preparation method and application thereof

A porous metal, organic framework technology, applied in the analysis of materials, material electrochemical variables, material analysis by electromagnetic means, etc., can solve the problem of no organometallic ferrocene/MOF-5 electrocatalytic performance, etc., and achieve low cost. , The process is simple, the effect is not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

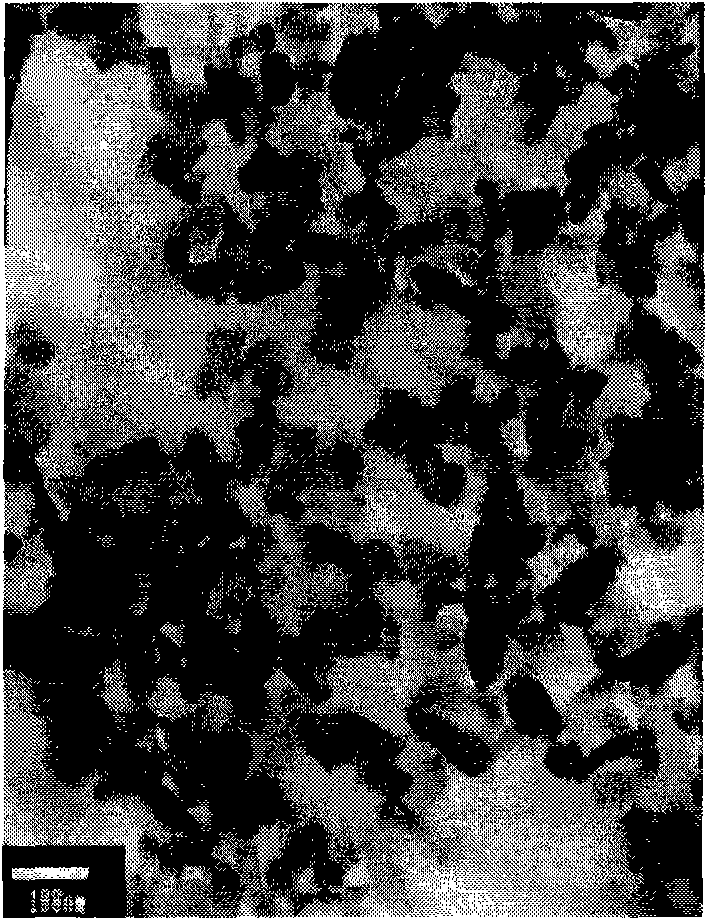

[0029] a. References (T. Loiseau, C. Serre, C. Huguenard, G. Fink, F. Taulelle, M. Henry, T. Bataille and G. Ferey, Chem-eur J, 2004, 10, 1373-1382. ) Aluminum nitrate (2.50g) and terephthalic acid (1.66g) were added to 65mL of N,N-dimethylformamide solvent, magnetically stirred at room temperature to completely dissolve, then the mixed solution was transferred to 100mL with The stainless steel reaction kettle lined with polytetrafluoroethylene is sealed and placed in an oven at 220 ° C. Under the action of self-generated pressure, it is heated and crystallized for three days. The oven was closed to obtain a white slurry product. The product was vacuum filtered, washed with N,N-dimethylformamide, and then vacuum-dried at 50° C. for 18 hours to obtain a white block product. The resulting product is ground and calcined. The calcination temperature is 280°C.

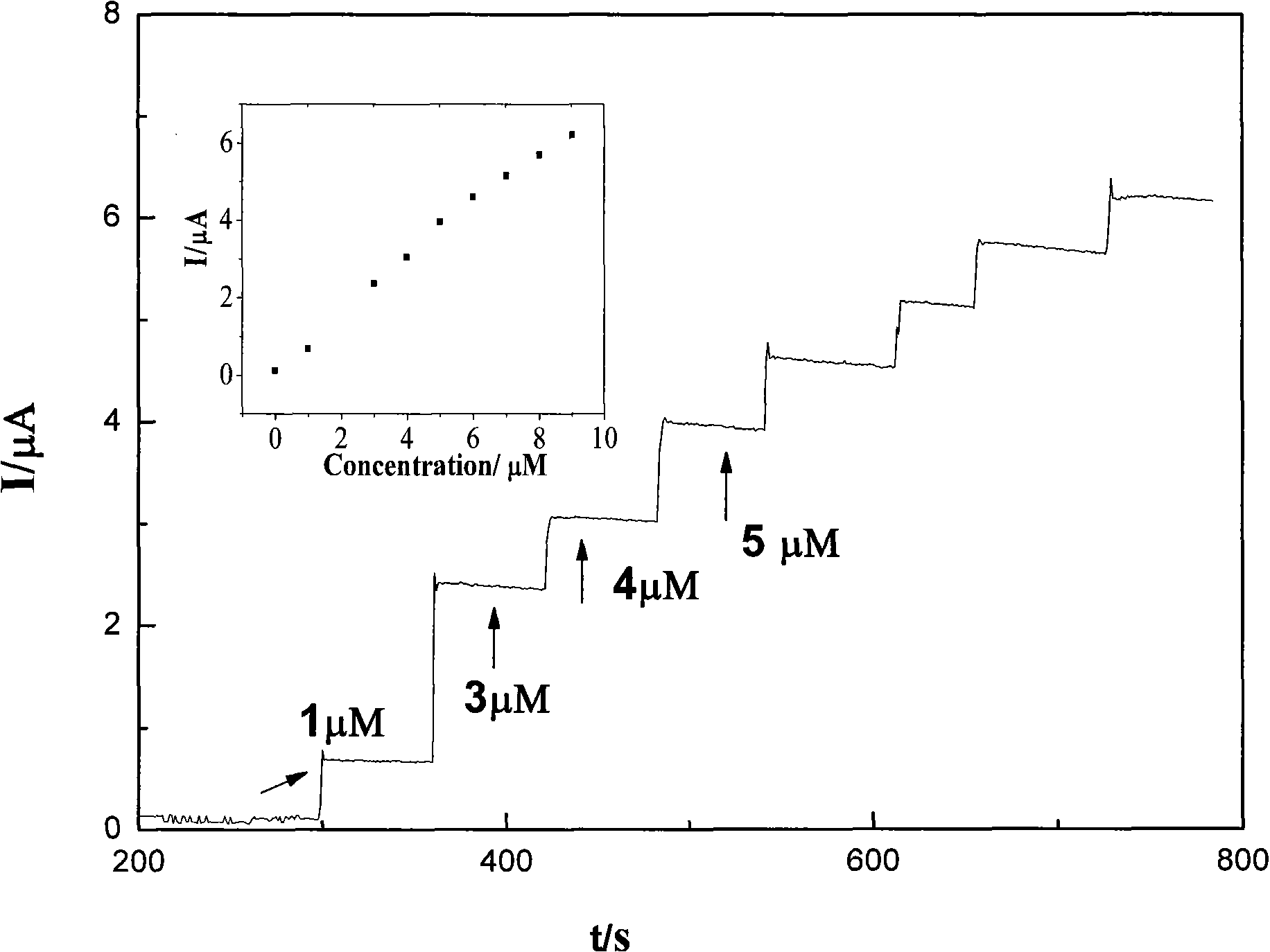

[0030] B. put ferrocene and calcined metal-organic framework compound (mass ratio is 0.5: 1) into two side pipes in the...

Embodiment 2

[0034] a Same as Example 1a

[0035] b. put ferrocene and calcined metal-organic framework compound (mass ratio is 1: 1) into two side pipes in the H-type reaction device respectively, vacuumize (10 -4 Pa), heated at 300°C for 48h, then naturally cooled to room temperature, washed several times with ether, and then vacuum-dried at 50°C for 18h to obtain a brown product.

[0036] c. Electrode modification and detection

[0037] At a working voltage of -100mV, record the amperometric response of the modified electrode to hydrogen peroxide. Others are the same as 1c.

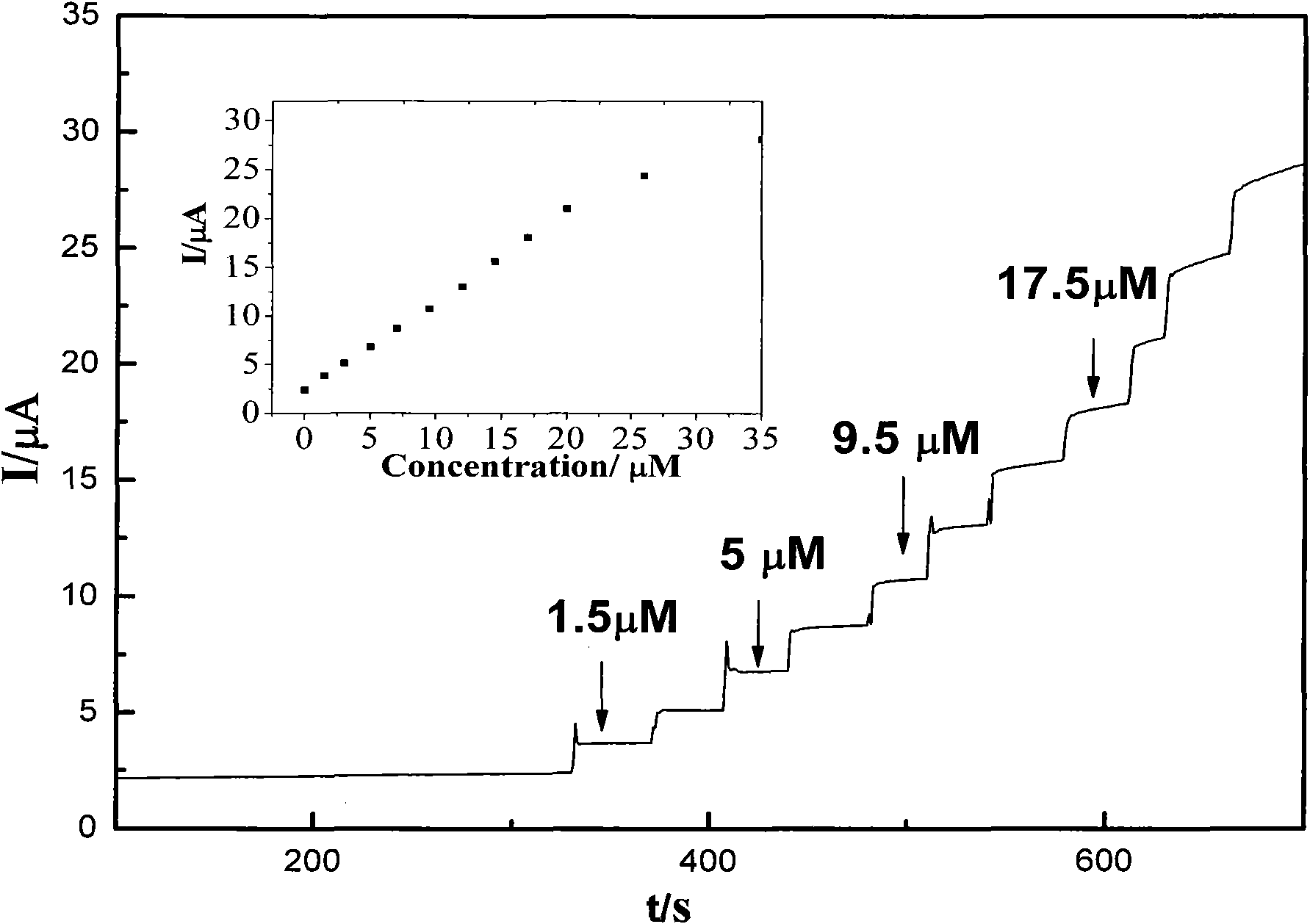

Embodiment 3

[0039] a Same as Example 1a

[0040] B. put ferrocene and calcined metal-organic framework compound (mass ratio is 2: 1) into two side pipes in the H-type reaction device respectively, vacuumize (10 -4 Pa), heated at 300°C for 48h, then naturally cooled to room temperature, washed several times with ether, and then vacuum-dried at 50°C for 18h to obtain a brown product.

[0041] c. Electrode modification and detection

[0042] At a working voltage of 0 mV, record the amperometric response of the modified electrode to hydrogen peroxide. Others are the same as 1c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com