Clean production method for preparing iminodiacetonitrile by taking hydroxy acetonitrile as raw material

A technology of iminodiacetonitrile and hydroxyacetonitrile, which is applied in the preparation of carboxylic acid nitriles, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as poor stability, difficult waste liquid treatment, and unstable process, and meet the reaction conditions. Mild, less treatment, lower cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

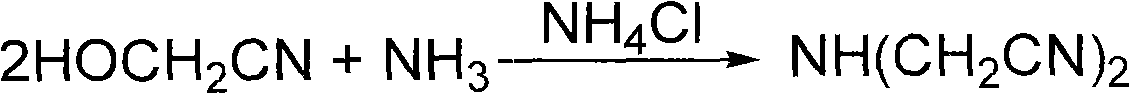

Image

Examples

Embodiment 1

[0027] Add hydroxyacetonitrile (50%) 300 grams (2.63 moles) in the reaction flask of 500 milliliters, add ammonium chloride 23 grams (0.43 moles) under stirring, then give system heating, when being heated to 90 ℃, start to add ammoniacal liquor, Control the drip rate of ammonia water to ensure that the pH value of the reaction solution is between 5-8, and simultaneously control the temperature of the reaction system between 110-130°C. After adding 90 grams (1.32 moles) of ammonia water (25%), the dropwise addition can be stopped, and the heat preservation at 100-110° C. for half an hour is continued, the reaction solution is cooled to 20-25° C., kept stirring for 1 hour, and suction filtered to obtain 104 gram of iminodiacetonitrile wet product, yield 75%, obtain mother liquor 295 grams simultaneously.

[0028] Heat 295 grams of mother liquor obtained by suction filtration to 75°C for dehydration under reduced pressure, the vacuum degree of dehydration is -0.08~-0.09Mpa, afte...

Embodiment 2

[0030] Add hydroxyacetonitrile (50%) 300 grams (2.63 moles) in the reaction flask of 1000 milliliters, add 130 grams of mother liquors to be applied mechanically in Example 1 under stirring, then give system heating, when being heated to 90 ℃, start to add ammoniacal liquor, control The dropping speed of ammonia water is to ensure that the pH value of the reaction solution is between 5-8, and at the same time control the temperature of the reaction system between 100-130°C. After adding 88 grams (1.29 moles) of ammonia water (25%), the dropwise addition can be stopped, continue to be incubated at 100-110° C. for half an hour, and the reaction solution is cooled to 20-25° C., kept stirring for 1 hour, and suction filtered to obtain 125 gram of iminodiacetonitrile wet product, yield 88%, obtain mother liquor 380 grams simultaneously.

[0031] Heat 380 grams of mother liquor obtained by suction filtration to 75°C for dehydration under reduced pressure. The dehydration vacuum degr...

Embodiment 3

[0033] Add hydroxyacetonitrile (50%) 300 grams (2.63 moles) in the reaction bottle of 1000 milliliters, add embodiment 2 under stirring and wait to apply mechanically 160 grams of mother liquor, then give system heating, when being heated to 90 ℃, start to add ammoniacal liquor, control The dropping speed of ammonia water is to ensure that the pH value of the reaction solution is between 5-8, and at the same time, the temperature of the reaction system is controlled between 110-130°C. After adding 86 grams (1.26 moles) of ammonia water (25%), you can stop the dropwise addition, continue to keep warm at 100-110°C for half an hour, adjust the pH value of the reaction solution to 2-4, cool to 20-25°C, and keep stirring After 1 hour, 132 grams of iminodiacetonitrile wet product was obtained by suction filtration, with a yield of 91%, and 405 grams of mother liquor were obtained at the same time.

[0034] Heat 405 grams of mother liquor obtained by suction filtration to 75°C for dehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com