Polystyrene nanoparticle preparation method

A polystyrene nanometer and particle technology is applied in the field of preparation of polystyrene nanoparticles, which can solve the problems of complex equipment and large particle size, and achieve the effects of easy post-processing, low cost, and favorable utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

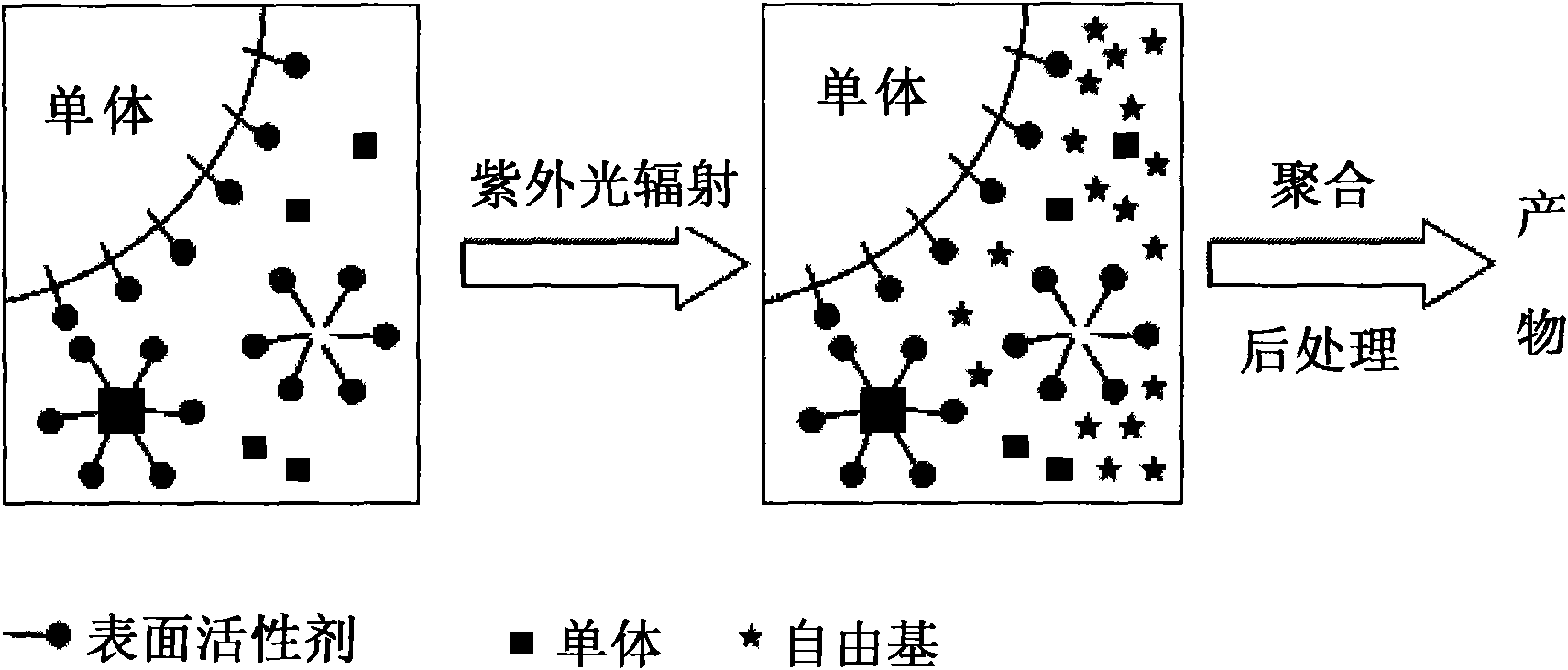

Method used

Image

Examples

Embodiment 1

[0026] 1) Styrene 5g, 1-[4-(2-hydroxyethoxy)-2-hydroxyl-2', 2'-dimethylethanone 0.2g (20 mmol per liter), hexadecyl 0.2 g of trimethylammonium bromide and 45 g of deionized water were added to a reaction flask with a quartz cap and mixed, passed through nitrogen, stirred and emulsified for 30 minutes, and the stirring speed was 300 rpm;

[0027] 2) Place the emulsified reaction solution in step 1) under the radiation of a 375W straight tube high-pressure mercury lamp, adjust the incident light intensity to 8000 microwatts per square centimeter, and react for 2.5 hours with stirring at a speed of 300 rpm. After the reaction is completed, the material is discharged and filtered with a G4 funnel, and the filtrate is the product polystyrene nanoparticles.

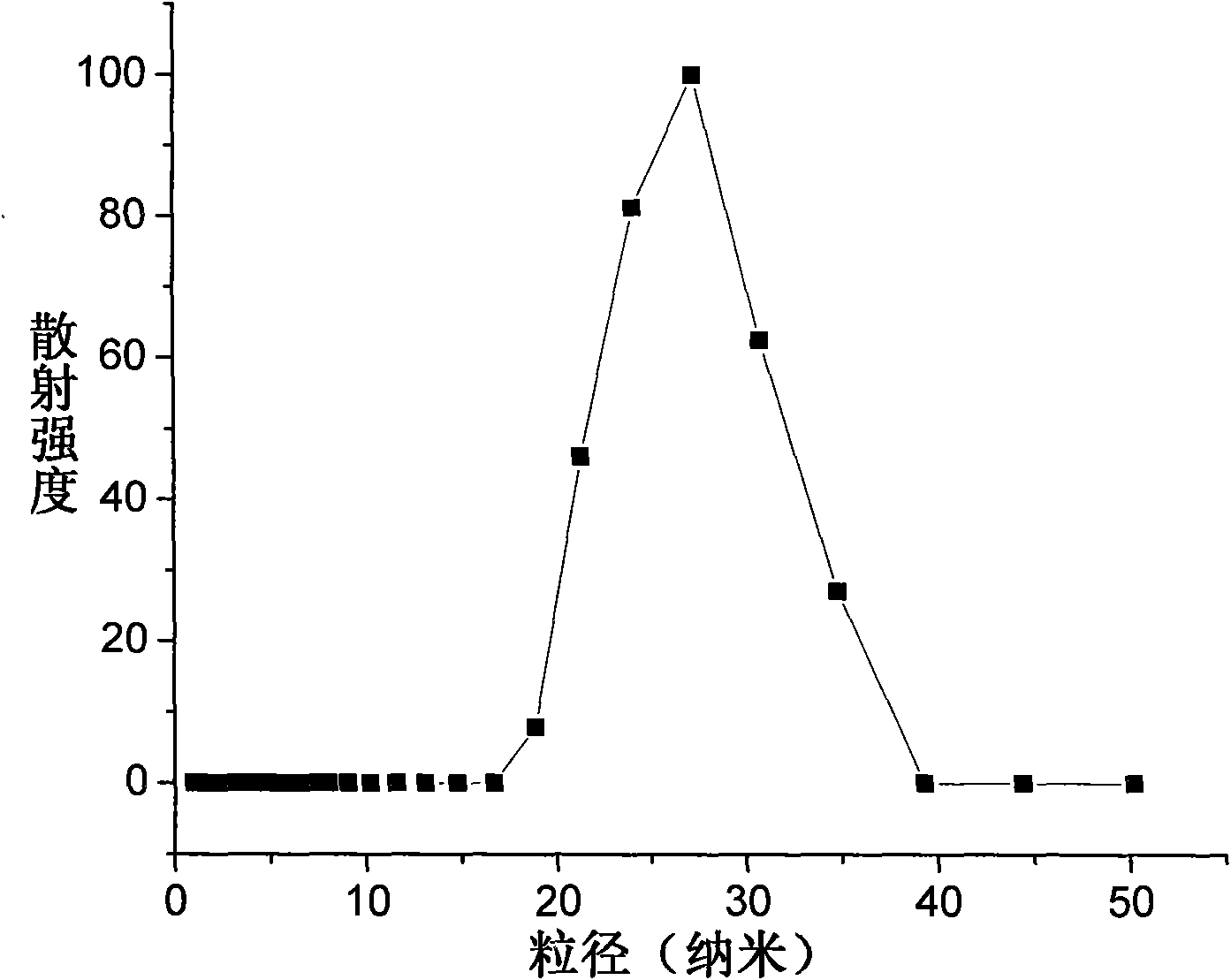

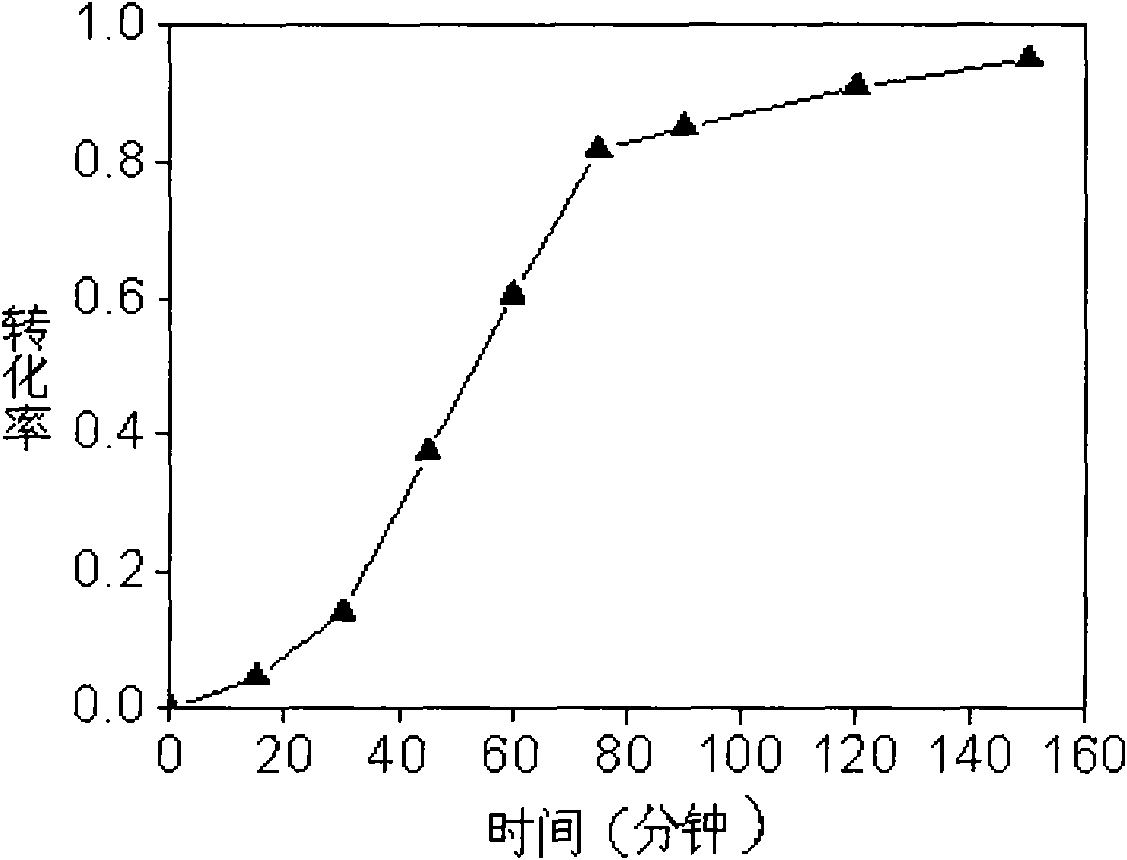

[0028] From figure 2 It can be seen from the figure that the particle size of polystyrene nanoparticles is about 25 nanometers; image 3 It can be seen that the conversion rate of styrene can reach more than 95%.

Embodiment 2

[0030] 1) Styrene 5g, 2-hydroxyl-2-methyl-1-phenyl-1-acetone 0.15g (20 mmol per liter), cetyltrimethylammonium bromide 0.2g and deionized water 45g, added to a reaction bottle with a quartz cap and mixed, stirred and emulsified with nitrogen for 30 minutes, and the stirring speed was 300 rpm;

[0031] 2) Place the emulsified reaction solution in step 1) under the radiation of a 375W straight tube high-pressure mercury lamp, adjust the incident light intensity to 8000 microwatts per square centimeter, and react for 2.5 hours with stirring at a speed of 300 rpm. After the reaction is completed, the material is discharged and filtered with a G4 funnel, and the filtrate is the product polystyrene nanoparticles.

[0032] From Figure 4 It can be seen that the particle size of polystyrene nanoparticles is about 25 nanometers; Figure 5 It can be seen that the conversion rate of styrene can reach 100%.

Embodiment 3

[0034] 1) Weigh 3 g of styrene, 2 g of divinylbenzene, 0.2 g of 1-[4-(2-hydroxyethoxy)-2-hydroxyl-2', 2'-dimethylethanone (20 mmol per liter), 0.2 g of cetyltrimethylammonium bromide and 45 g of deionized water were added into a reaction flask with a quartz cover and mixed, nitrogen was passed, stirring and emulsifying was carried out for 30 minutes, and the stirring speed was 300 revolutions per minute;

[0035] 2) Place the emulsified reaction solution in step 1) under the radiation of a 375W straight tube high-pressure mercury lamp, adjust the incident light intensity to 8000 microwatts per square centimeter, and react for 2.5 hours with stirring at a speed of 300 rpm. After the reaction is completed, the material is discharged and filtered with a G4 funnel, and the filtrate is the product polystyrene nanogel particles.

[0036] From Figure 6 It can be seen that the particle diameter of the polystyrene nanogel particles is about 30 nanometers; Figure 7 The conversion ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com