Device for purifying formic acid solution with interval azeotropic distillation and method thereof

A technology of azeotropic distillation and formic acid, which is applied in the field of formic acid solution purification by batch azeotropic distillation, can solve problems such as complex process, environmental pollution, and difficult industrial realization, and achieve simple device structure, reasonable process flow, and convenient recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

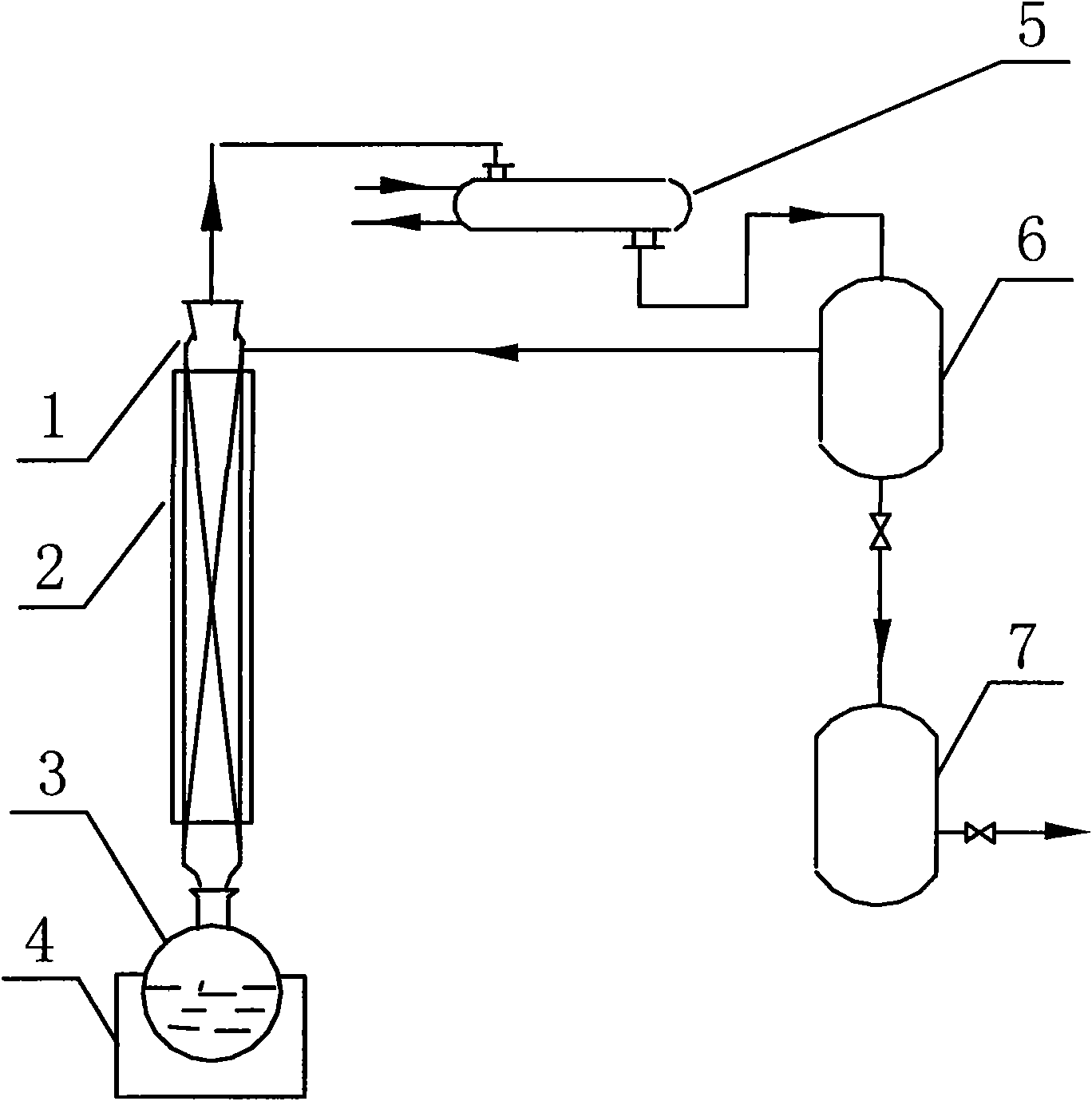

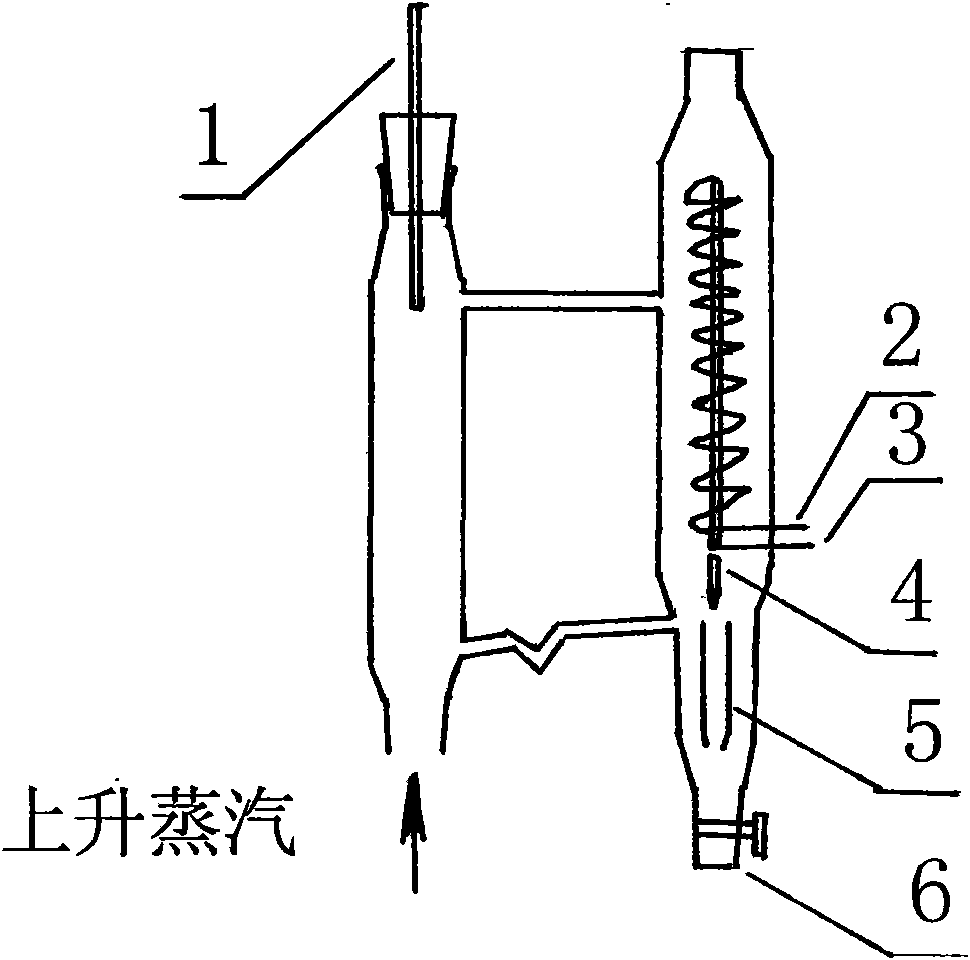

[0022] The present invention adopts intermittent azeotropic rectification equipment, as shown in the figure, figure 1 It is a schematic diagram of the device of the present invention. Among them, 1 is the body of the rectification tower, 2 is the insulation layer, 3 is the tower kettle, 4 is the heating jacket, 5 is the condenser, 6 is the phase separator, and 7 is the product storage tank. figure 2 Schematic diagram of the condenser used for the experiment. Among them, 8 is a thermometer, 9 is a condensed water outlet, 10 is a condensed water inlet, 11 is a reflux ratio regulator, 12 is a phase separator in a condensation chamber, and 13 is a sampling port.

[0023] An insulation layer 2 is installed outside the tower body 1, the lower end of the rectification tower body 1 is connected to the tower kettle 3, and the upper end is respectively connected to the condenser 5 and the phase separator 6, and the phase separator 6 is respectively connected to the condenser 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com