Liquid adsorbent and method for controlling arsenic pollution of lake water

A liquid adsorbent, arsenic pollution technology, applied in the field of treatment, can solve the problems of difficult to fully adjust the pH value, increase the cost of adsorption materials, etc., and achieve the effect of strong adsorption and precipitation, convenient use and operation, and less dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

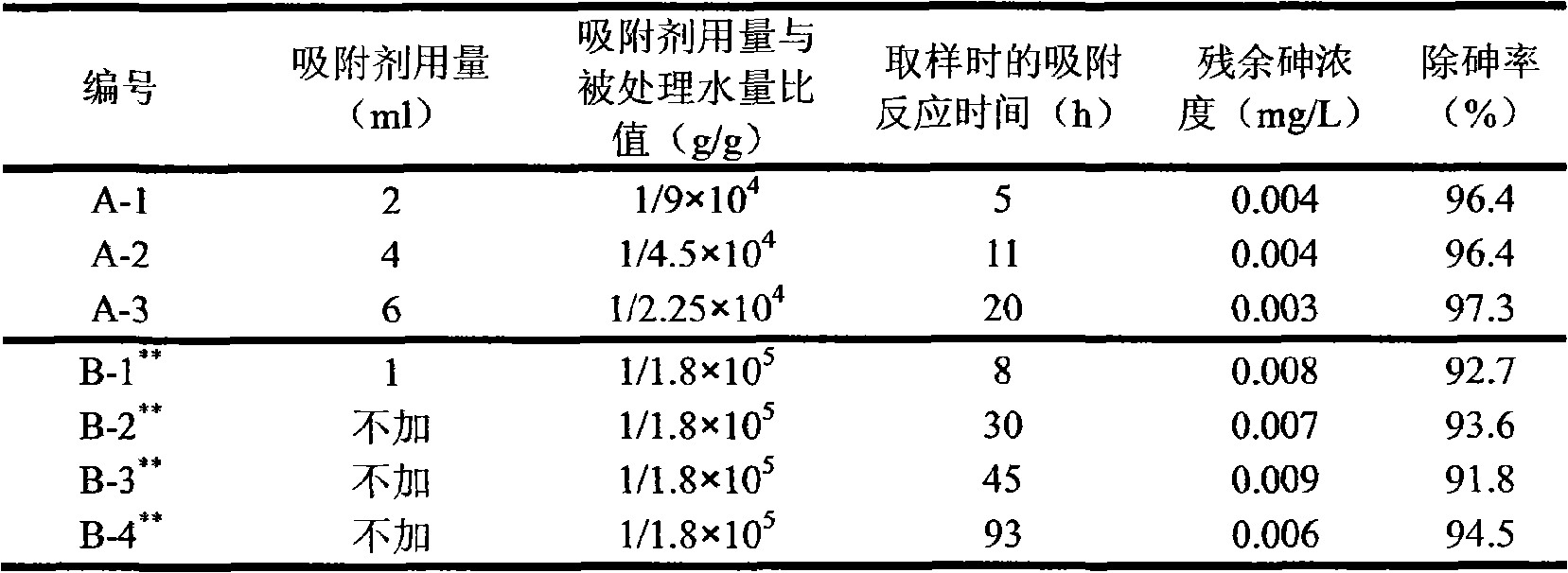

Embodiment 1

[0037] Fe for liquid adsorbent 2 (SO 4 ) 3 Mix well with tap water or deionized water, and its mass concentration is 200g / L. Take 50 liters of Yangzong seawater sample with an arsenic concentration of 0.110 mg / L and fill it in a plastic barrel with a diameter of 38 cm and a height of 56 cm. Take out 2 mL of the adsorbent solution in a glass beaker, dilute the solution to 20 mL with tap water, then spray the surface of the experimental water in the plastic bucket with an atomizer, and stir gently for 2 minutes. At 5 hours a water sample was taken from the bucket, filtered and tested by atomic fluorescence spectroscopy. As a result, the concentration of arsenic has dropped to 0.004mg / L, and the removal rate of arsenic is 96.4%. Continue to use 2mL of high-concentration liquid adsorbent, repeat the above dilution, spraying and stirring operations, and take a sample after 6 hours of aging for analysis. The arsenic concentration is still 0.004mg / L, indicating that 50 liters of ...

Embodiment 2

[0039] FeCl for liquid adsorbent 3 Mix well with tap water or deionized water, and its mass concentration is 400g / L. The operating procedure is the same as that described in Example 1, but the amount of liquid adsorbent solution added is only 1 mL, and after dilution to 10 mL, the surface of a bucket of experimental water is sprayed and stirred slightly for 2 minutes. The concentration of arsenic was 0.008mg / L when the sample was analyzed after 6 hours, and the arsenic removal rate was 92.7%. 5 , that is, 1 ton of adsorbent solid can treat 180,000 cubic meters of lake water.

Embodiment 3

[0041] The operating procedure is the same as that described in Example 2, but the amount of the liquid adsorbent solution added is only 0.5 mL, and after dilution to 10 mL, the surface of a bucket of experimental water is sprayed and stirred slightly for 2 minutes. The concentration of arsenic was 0.006mg / L when the sample was analyzed after 6 hours, and the arsenic removal rate was 94.5%. 5 , That is, 1 ton of adsorbent solid can treat 360,000 cubic meters of lake water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com