Method for preparing radiation and aging resistant polypropylene alloys

A polypropylene, anti-radiation technology, applied in organic chemistry and other directions, can solve the problems of mechanical properties decline, discoloration, etc., and achieve the effects of reduced elongation at break, simple preparation method, and strong anti-radiation aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 0.12 mol of maleic anhydride, 0.1 mol of 2,2,6,6-tetramethyl-4-piperidinol and 60 ml of toluene into a three-necked flask equipped with a stirrer and a thermometer, and stir mechanically to make it evenly mixed . The temperature was raised to 50° C. for the esterification reaction, and the reaction was completed after stirring at this temperature for 30 minutes. Pour the reactant into a mixture of chloroform and saturated saline, the volume ratio of chloroform to saturated saline is 3:1, then move the chloroform and saturated saline solution containing the reactant to a separatory funnel for shaking to separate layers, Unreacted maleic anhydride was removed. Chloroform and toluene were distilled off from the lower layer under reduced pressure accordingly. The white solid obtained was mono(2,2,6,6-tetramethyl-4-piperidinolyl)maleate (TPM).

Embodiment 2

[0031] Add 0.15mol of maleic anhydride, 0.1mol of 1,2,2,6,6-pentamethyl-4-piperidinol and 80ml of xylene into a three-necked flask equipped with a stirrer and a thermometer, and stir mechanically to make it well mixed. The temperature was raised to 60° C. for the esterification reaction, and the reaction was completed after stirring at this temperature for 60 minutes. Pour the reactant into a mixture of chloroform and saturated saline, the volume ratio of chloroform to saturated saline is 2.5:1, then move the chloroform and saturated saline solution containing the reactant to a separatory funnel for shaking to separate layers, Unreacted maleic anhydride was removed. Chloroform and xylene were distilled off from the lower layer under reduced pressure accordingly. The white solid obtained was mono(1,2,2,6,6-pentamethyl-4-piperidinolyl)maleate (MPM).

Embodiment 3-6

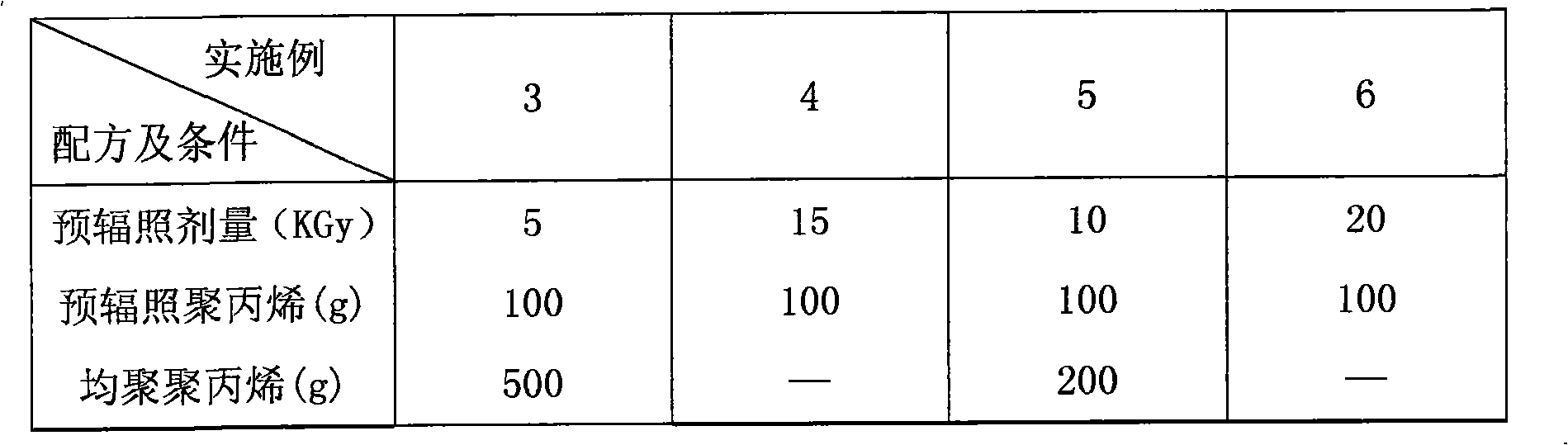

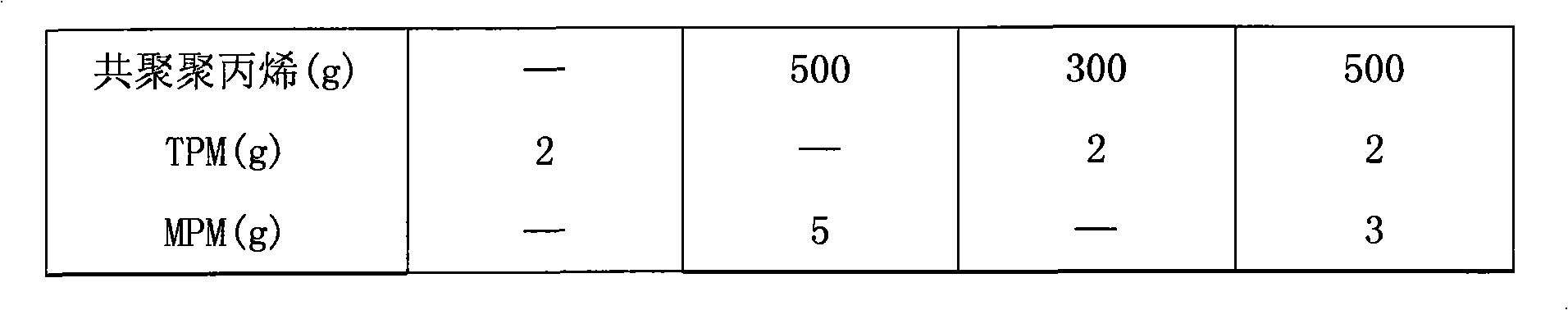

[0033] An electron accelerator was used to pre-irradiate homopolypropylene (iPP), and the irradiation dose was listed in Table 1 to prepare pre-irradiated polypropylene with macromolecular peroxides.

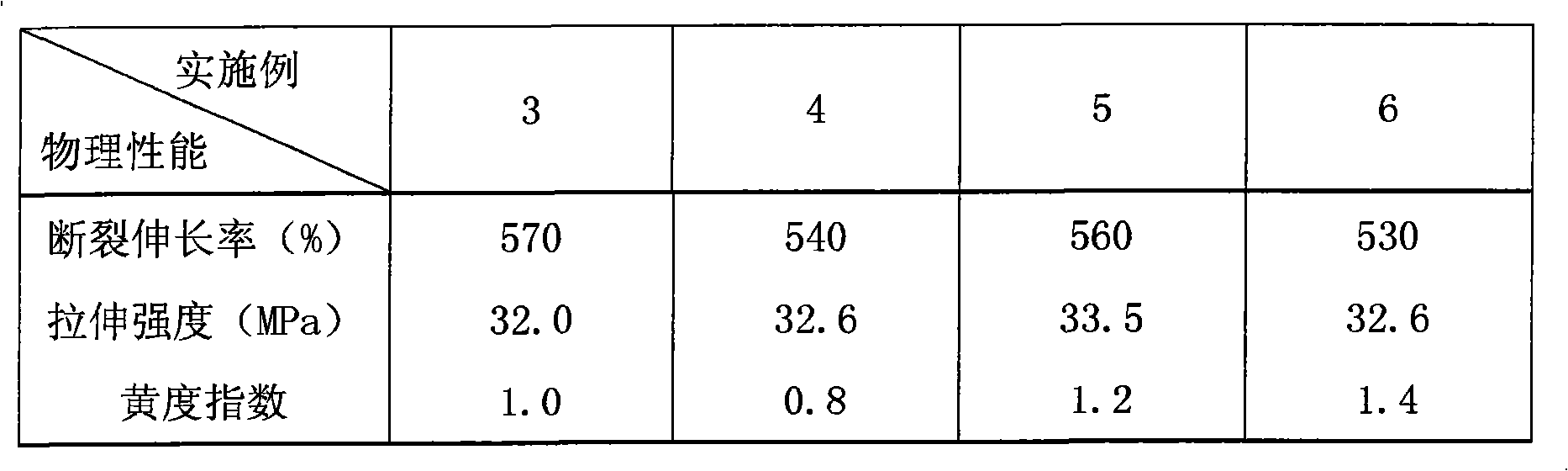

[0034] Homopolypropylene, ethylene-propylene random copolymer or their blends, TPM, MPM or their mixtures, and pre-irradiated polypropylene are subjected to reactive extrusion grafting to prepare a radiation-resistant aging polypropylene resin. The reaction extrusion grafting temperature is 200° C., the screw speed is 80 rpm, and the material residence time is 3 minutes. The ratio of anti-radiation aging polypropylene material is shown in Table 1. The melt flow rate of the homopolypropylene used is 2.0g / 10min, and the melt flow rate of the ethylene-propylene random copolymer used is 3.0g / 10min. in Table 2.

[0035] The prepared polypropylene resin grafted with a hindered amine stabilizer is mechanically mixed with a thermoplastic elastomer, and added to a twin-screw extruder f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com