Soybean grease extracting method

An extraction method, soybean oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of no other nutritional value, complex process, loss of nutritional components, etc., to achieve vegetable oil without solvent residue, high nutritional value, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

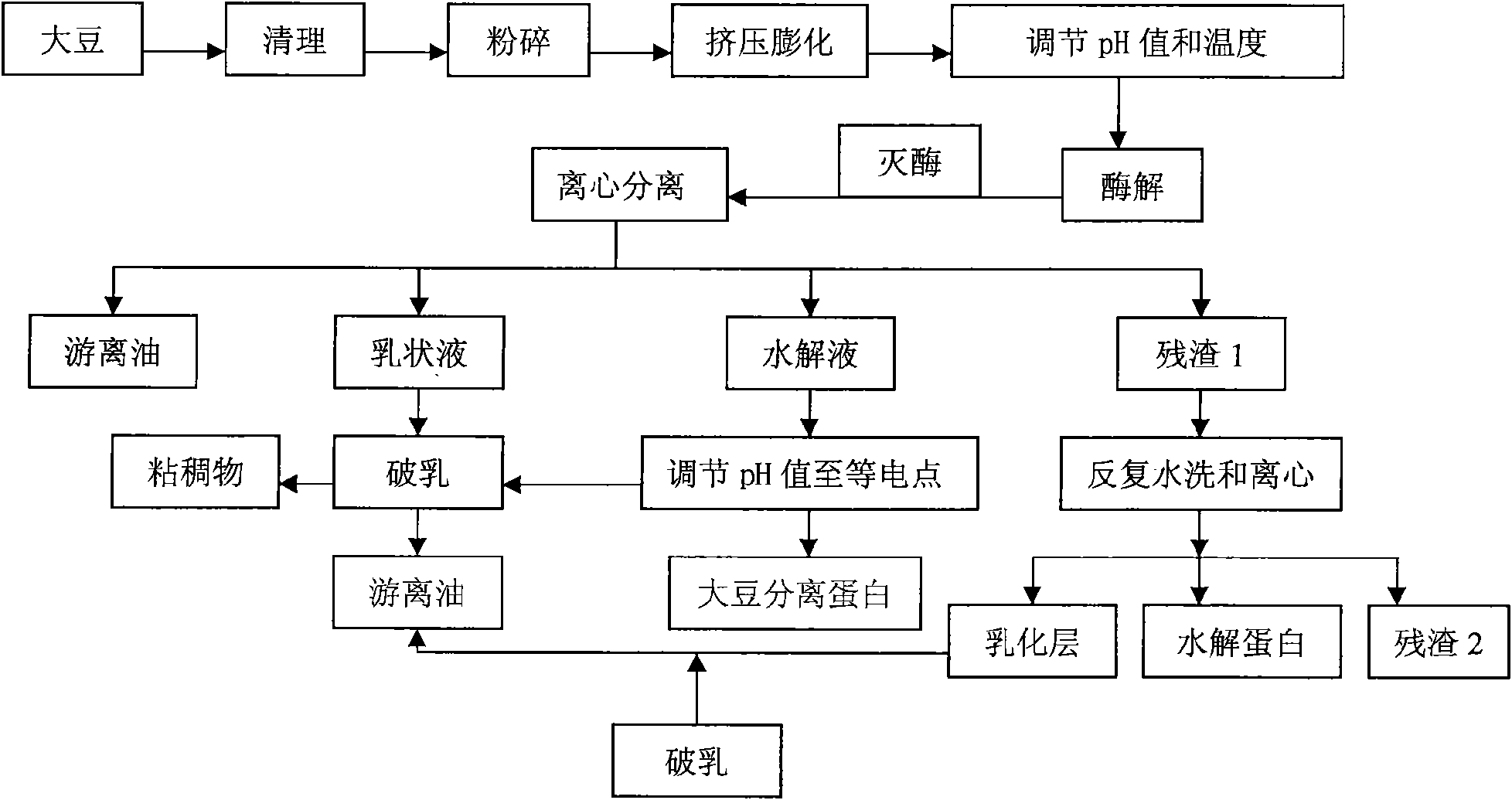

Method used

Image

Examples

experiment example 1

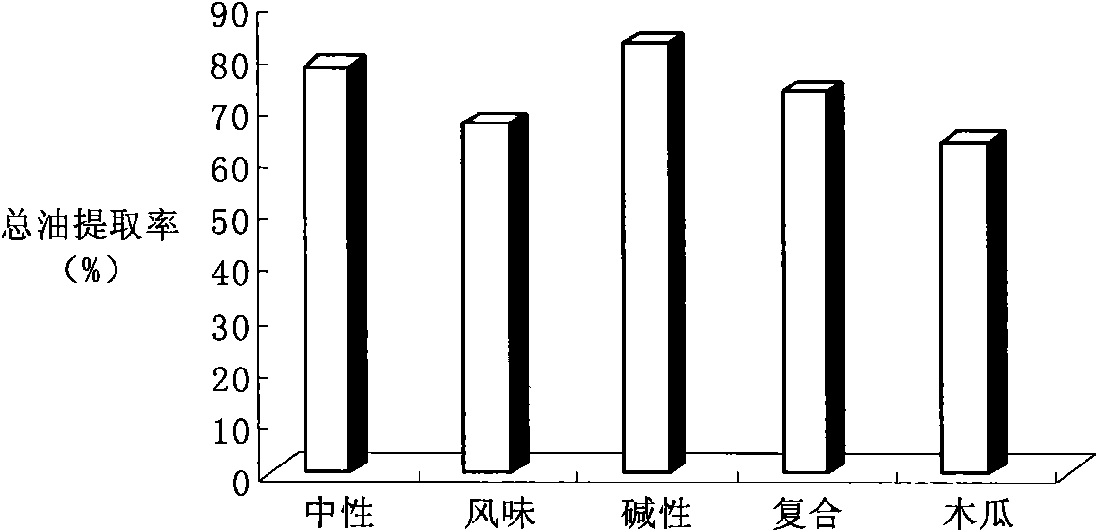

[0057] Experimental example 1 Screening experiment of optimal parameters of soybean protein enzymatic hydrolysis process conditions

[0058] 1 Materials and methods

[0059] 1.1 Materials and reagents

[0060] Soybean Kennong 42 cultivated by Heilongjiang Academy of Agricultural Sciences

[0061] Alcalase alkaline endoprotease Danish novo company

[0062] Flavor protease Danish novo company

[0063] Papain Danish novo company

[0064] Compound protease Danish novo company

[0065] AS1398 neutral protease Danish novo company

[0066] 1.2 Main instruments and equipment

[0067] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0068] Electronic Analytical Balance Merlot-Toledo Instruments (Shanghai) Co., Ltd.

[0069] Centrifuge Beijing Medical Centrifuge Factory

[0070] Precision Electric Mixer Jiangsu Jintan City Ronghua Instrument Manufacturing Co., Ltd.

[0071] Electric constant temperature water bath Yuyao Dongfang Electrical Instrument Factory

[0072] ...

experiment example 2

[0126] Experimental example 2 Optimal experiment of process parameters in crushing, extruding and puffing pretreatment process of raw materials before enzymatic hydrolysis

[0127] Based on the best water enzymatic extraction process of soybean oil and protein determined in Experimental Example 1, a single factor extrusion test was carried out to determine the parameters of each extrusion expansion system (sleeve temperature, die hole diameter, screw speed, material moisture content) range. Taking the oil extraction rate, protein extraction rate, and total sugar yield in the hydrolyzate as the investigation indicators, a response surface design experiment with 5 factors and 5 levels was carried out

[0128] 2.2 Main instruments and equipment

[0129] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0130] Electronic Analytical Balance Mellert-Toledo Instruments (Shanghai) Co., Ltd.

[0131] Centrifuge Beijing Medical Centrifuge Factory

[0132] Precision Electric M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screw diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com