Carbon-doped yttrium aluminium garnet crystal and two-step preparation method thereof

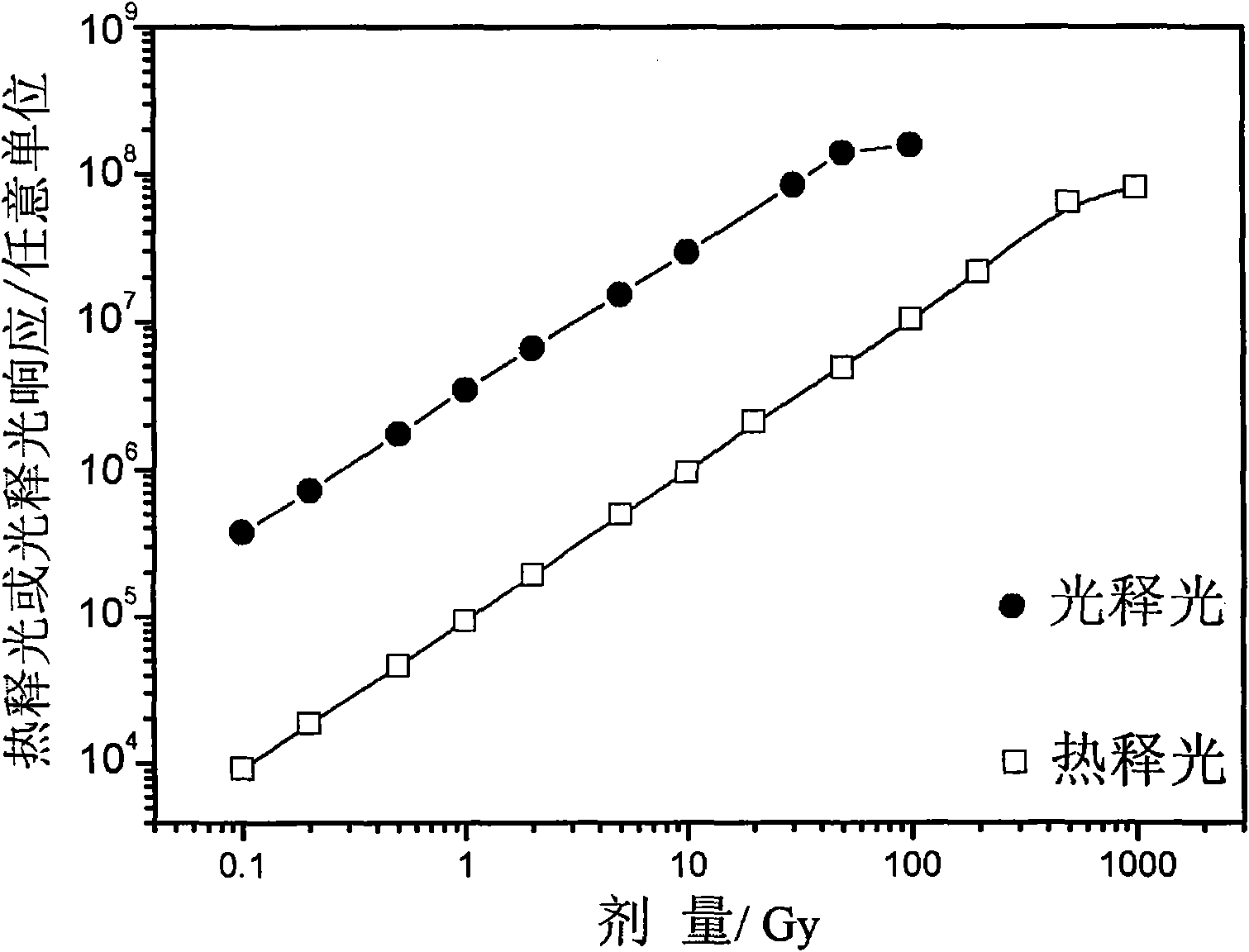

A technology for yttrium aluminum garnet and crystal, which is applied in the field of carbon-doped yttrium aluminum garnet crystal and its two-step preparation, can solve the problems of easy volatilization of carbon, influence on crystal stability, inability to obtain, etc., and achieve high thermoluminescence sensitivity and Optical luminescence sensitivity, improved performance, the effect of avoiding volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 2.5 mol or 255 grams of α-Al respectively 2 o 3 , 1.5mol or 338.7 grams of Y 2 o 3 , mixed and ground on a planetary ball mill for 24 hours, taken out and then cold-dried and pressed into shape for later use. The temperature gradient method is used to grow YAG crystals, and pure YAG in the [111] direction is selected as the seed crystal; the temperature gradient in the growth area is 30K / cm; after the furnace is installed, the vacuum is pumped to the furnace pressure -3 Pa, continue to heat up to 2253K, keep the temperature for 0.5h after the raw material is melted, and cool down at a cooling rate of 3K / h. The melt starts to slowly crystallize from the seed crystal, continue to cool down until the melt is completely crystallized, and then cool down to room temperature at a rate of 40K , open the furnace hood, and take out the crystals.

[0029] Colorless and transparent YAG crystals were grown without obvious inclusions and bubbles. Several wafers of 5 x 5 x 1...

Embodiment 2

[0033] Weigh 2.5 mol or 255 grams of α-Al respectively 2 o 3 , 1.5mol or 338.7 grams of Y 2 o 3 , mixed and ground on a planetary ball mill for 24 hours, taken out and then cold-dried and pressed into shape for later use. The temperature gradient method is used to grow YAG crystals, and pure YAG in the [111] direction is selected as the seed crystal; the temperature gradient in the growth area is about 40K / cm; -3 Pa, continue to heat up to 2253K, keep the temperature for 2 hours after the raw material is melted, and cool down at a cooling rate of 3K / h. The melt starts to slowly crystallize from the seed crystal, continue to cool down until the melt is completely crystallized, and then cool down to room temperature at a rate of 70K. Open the furnace hood and remove the crystals.

[0034] Colorless and transparent YAG crystals were grown without obvious inclusions and bubbles. Several wafers of 5 x 5 x 1 mm were cut in the crystal along the [111] direction. Put 100g of hig...

Embodiment 3

[0037] The preparation method of YAG crystal is the same as that in Example 1.

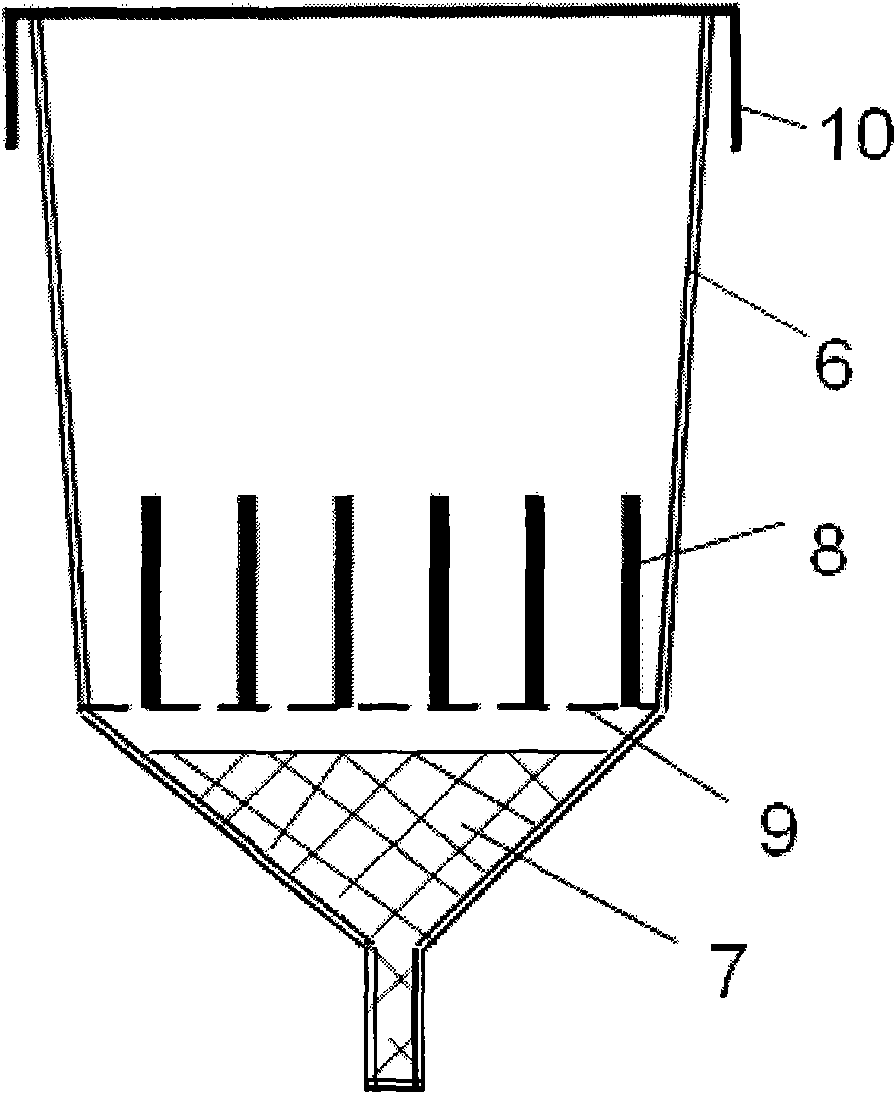

[0038]Cut several 5×5×5 mm wafers in the prepared YAG crystal along the [111] direction. Put 100g of carbon powder at the bottom of the crucible, place the YAG wafer on a support with holes in the crucible, and cover the crucible lid.

[0039] Install the furnace, vacuumize until the furnace pressure -3 Pa, continue to heat up to 2000K, and carry out carburizing treatment on the YAG wafer at constant temperature for 40 hours. The treatment process is carried out in a hydrogen reducing atmosphere, and then cooled to room temperature at a rate of 70K, and the furnace cover is opened to take out the crystal. The carbon doping amount in the crystal can be measured by glow discharge mass spectrometry, and the result shows that the carbon doping amount in the crystal is about 2000ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com