Process for extracting nano silicon oxide in natural quartz sand and painting thereof

A nano-silica, natural quartz technology, applied in the field of nano-materials, can solve the problems of distrust of nano-technology, inability to propose application methods of nano-materials, etc., and achieve the effect of improving mechanical strength and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Soak the washed Hainan Wenchang quartz sand in water, use hydrosulfite to reduce the ferrous ions in the quartz sand to trivalent, dissolve the ferric ions in water with hydrochloric acid, and get a purity of more than 99% after repeated washing of silica-quartz sand. At the same time, with the removal of iron, the sand particles also become smaller from a few millimeters to tens of microns. This phenomenon is considered to be that iron oxide acts as a bonding agent between quartz particles. After three times of crushing, the particle size of the sand is reduced from 50 microns to 1-5 microns.

[0029] Weigh 2 kg of 1-5 micron quartz sand and 18 kg of water, put them into a ball mill, add sodium polyacrylate (60 g) as a dispersant, and ball mill for 48 hours to obtain a 100 nm-sized nano-silica aqueous dispersion.

Embodiment 2

[0030] Embodiment 2: the step of preparing a batch weight part coating process is: a adds polymer polyacrylic acid amine and water in the nano silicon oxide dispersion obtained in the fourth step of claim 1, b at 5000 rpm Under the action of a separate high-speed shear emulsifier, slowly add water-based polyurethane resin emulsion to obtain nano-quartz sand coating.

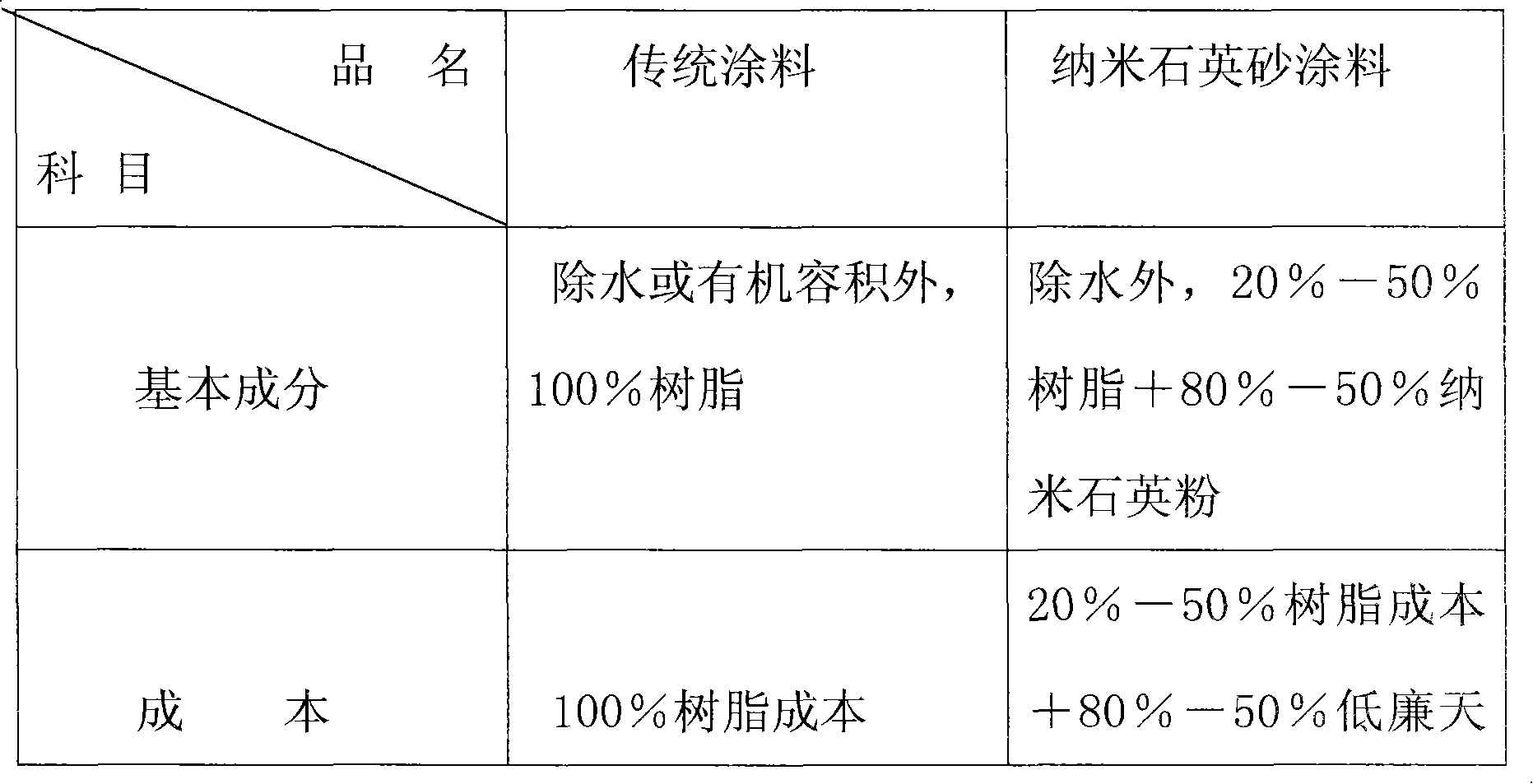

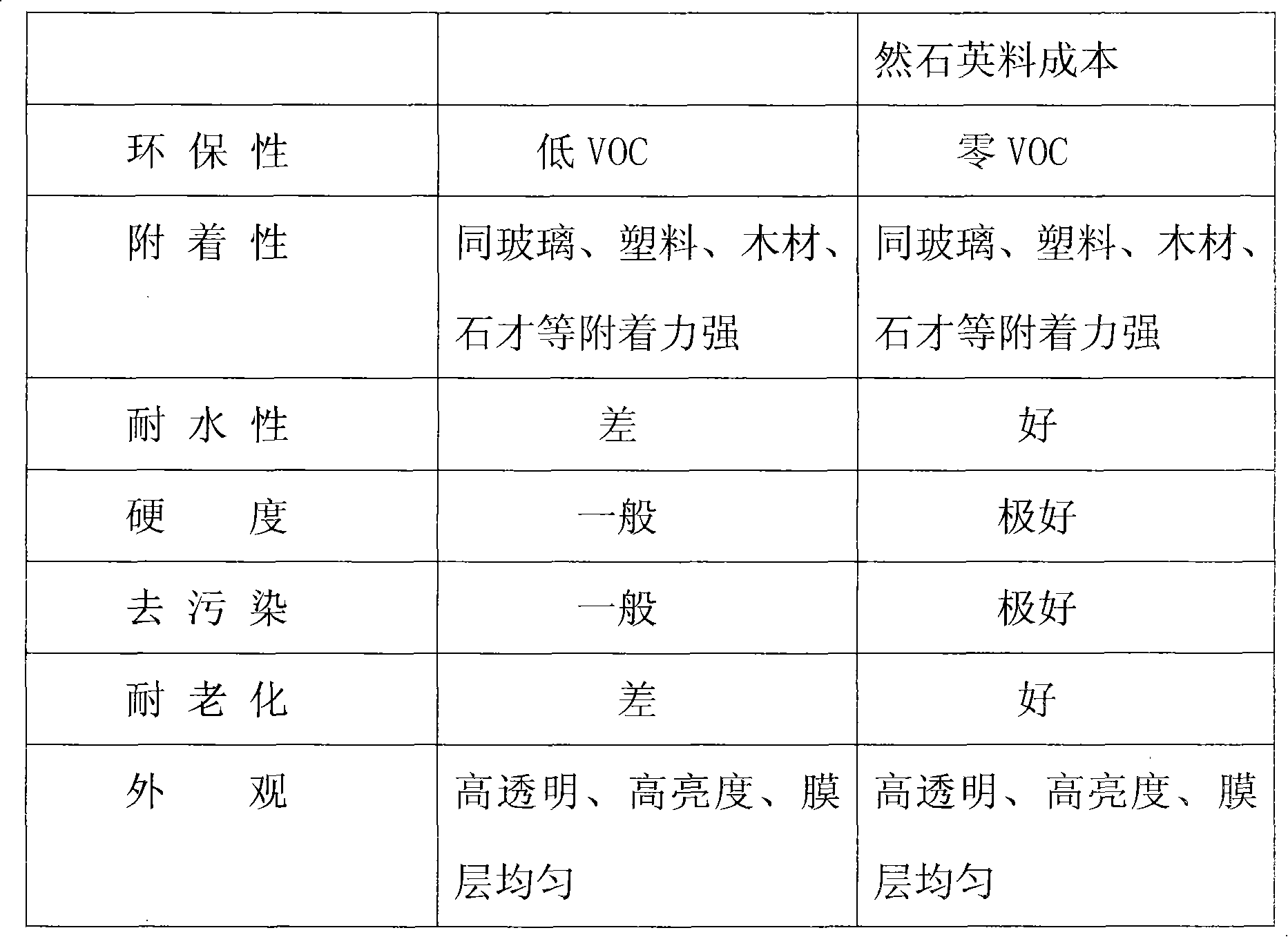

[0031] The coating method is carried out according to the following weight ratio and components:

[0032] water 10%

[0033] Polyacrylamine 0.5%

[0034] Resin 5%

[0035] Nano silica dispersion 84.5%

Embodiment 3

[0037] The coating method is carried out according to the following weight ratio and components:

[0038] water 30%

[0039] Polyacrylamide 0.55%

[0040] Resin 9.45%

[0041] Nano silica dispersion 60%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com