Preparation of polystyrene-divinylbenzene microspheres for blood purification

A technology of polystyrene and blood purification, applied in the direction of microsphere preparation, microcapsule preparation, suction equipment, etc., can solve the problems of large size dispersion of microspheres and low material utilization rate, and achieve uniform diameter dispersion, simple process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of larger diameter polystyrene seed microspheres:

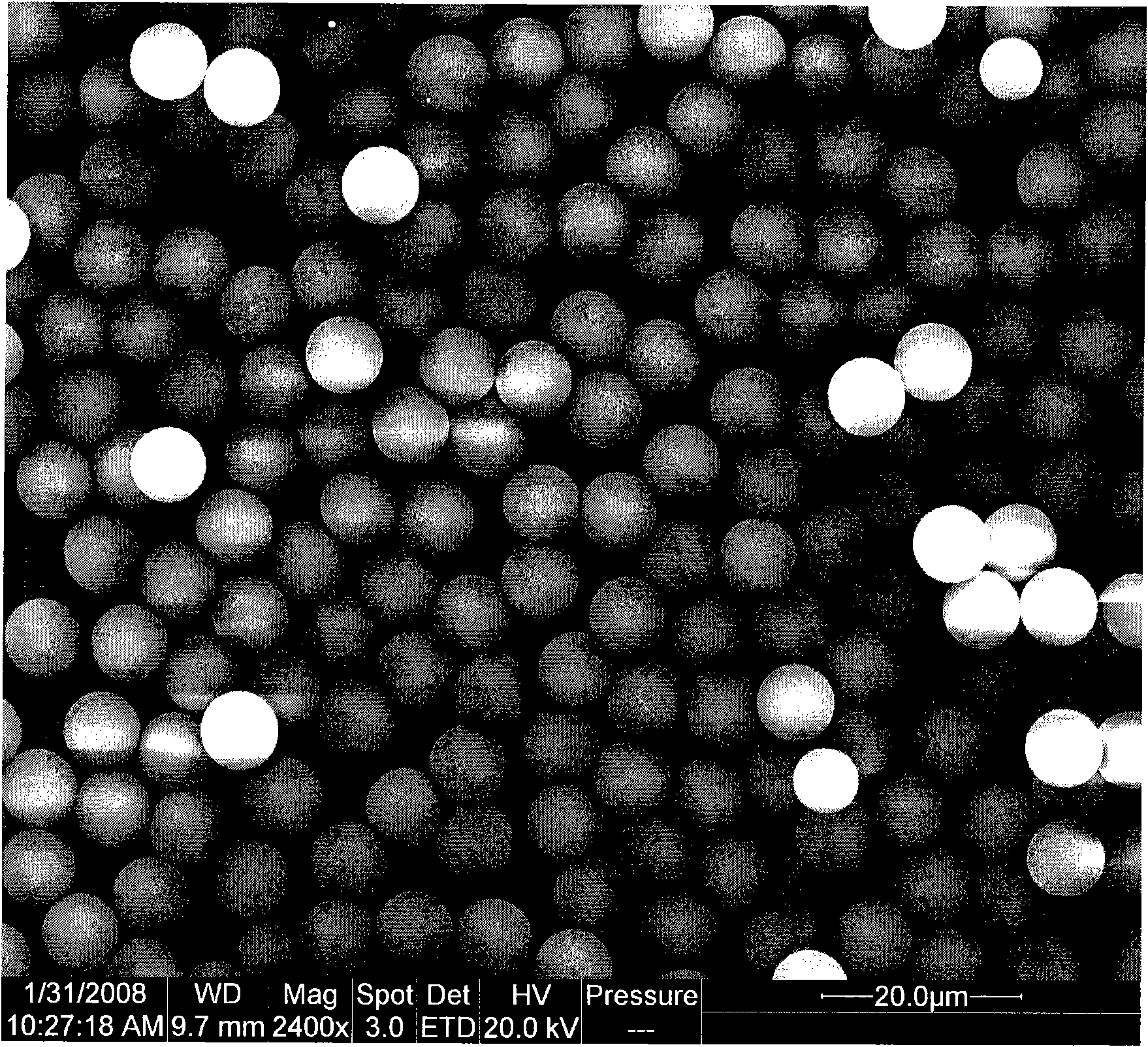

[0042] Dissolve 0.5g of hydroxypropyl cellulose and 400mg of benzoyl peroxide in a mixed solution of 30mL of absolute ethanol and 12mL of ethylene glycol methyl ether, then add 8mL of styrene monomer, and dissolve it ultrasonically at a temperature of 0-20°C to obtain Transparent solution, and replace oxygen with high-purity nitrogen bubbles for 30 minutes. Under 70 ℃ and mechanical stirring (stirring speed is 150r.p.m.) reaction 24 hours, obtain diameter about 8 micron (such as figure 1 shown) monodisperse polystyrene microspheres. After washing with ethanol for several times, the residual reactants were removed to obtain pure polystyrene microspheres, which were vacuum-dried at 40°C for 24 hours before use.

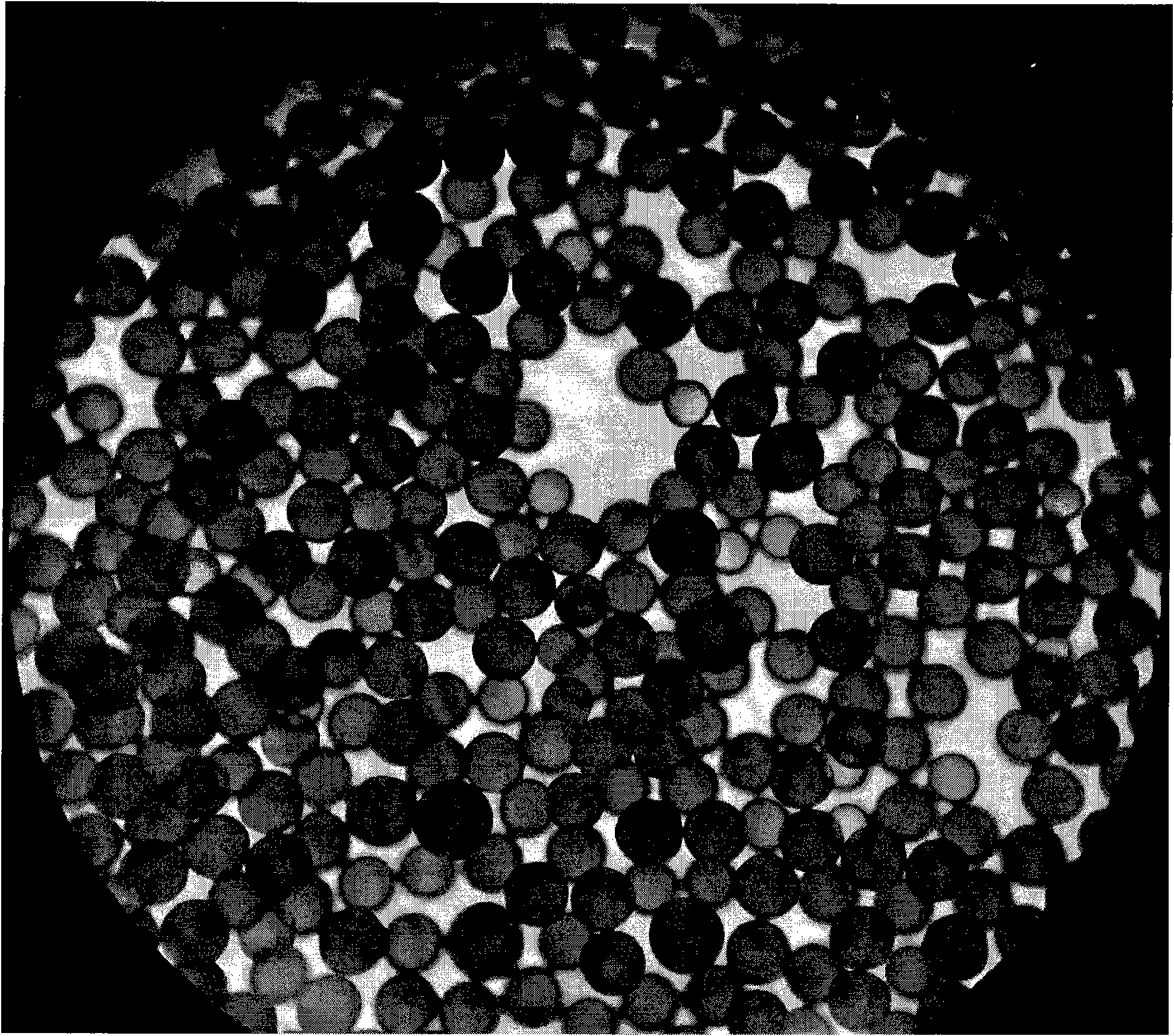

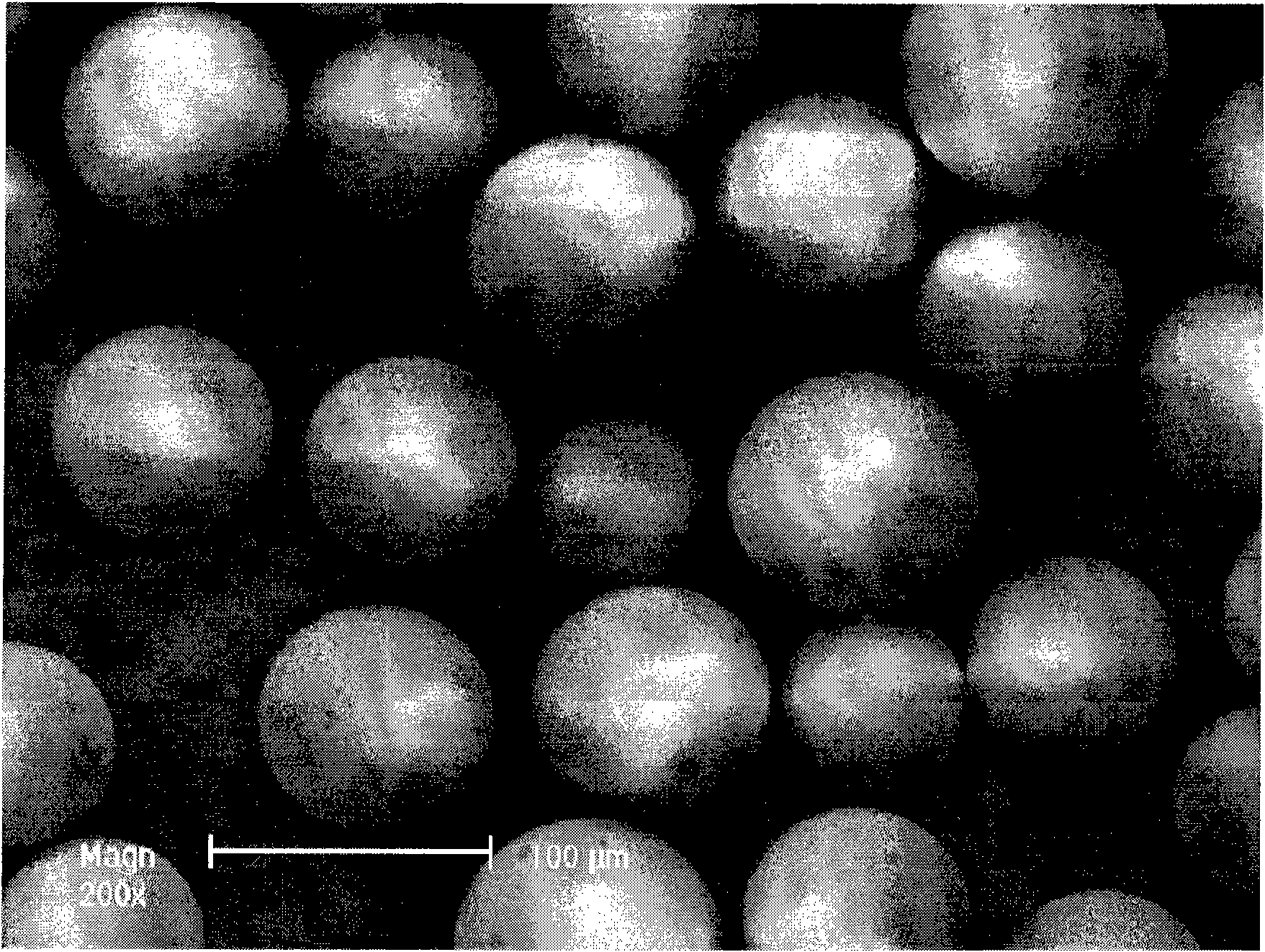

[0043] Preparation of larger diameter polystyrene-divinylbenzene crosslinked porous polymer microspheres:

[0044] 1.0g polystyrene seed microspheres (about 8μm in diameter) were uniformly dispers...

Embodiment 2

[0053] Preparation of larger diameter polystyrene seed microspheres:

[0054] Dissolve 1.0g of hydroxypropyl cellulose and 800mg of benzoyl peroxide in a mixed solution composed of 60mL of absolute ethanol and 24mL of ethylene glycol methyl ether, then add 16mL of styrene monomer, and ultrasonically dissolve at 0-20°C. A transparent solution was obtained, and deoxygenated by bubbling high-purity nitrogen for 30 min. Raise the temperature to 70° C., and react for 24 hours under mechanical stirring (stirring speed: 150 r.p.m) to obtain monodisperse polystyrene microspheres with a diameter of about 8 μm. The pure polystyrene microspheres were obtained after being washed several times with ethanol, and dried under vacuum at 40°C for 24 hours for use.

[0055] Preparation of larger diameter polystyrene-divinylbenzene crosslinked porous polymer microspheres:

[0056] 5.0g polystyrene seed microspheres (approximately 8 microns in diameter) were uniformly dispersed in 50mL containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com