Finishing oil for manufacturing of continuous silicone carbide fiber and application process thereof

A technology of silicon carbide fiber and oil agent, applied in fiber treatment, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of no oil agent, low molecular weight, etc., achieve simple equipment, improve performance uniformity, and process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

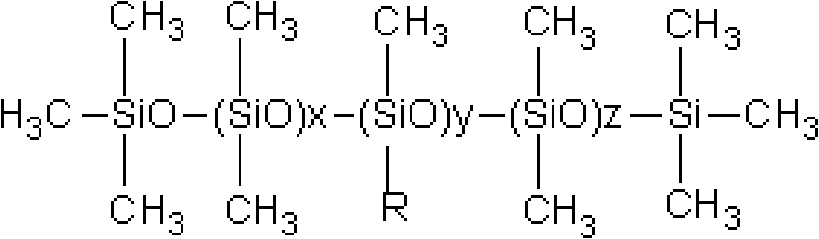

Method used

Image

Examples

Embodiment 1

[0039] Dissolve 2.5 g of amino-modified silicone oil (AMPS according to its English abbreviation, purity 98%, pH=7.5, viscosity 1500 mPa.s) in 500 ml distilled water, stir evenly, and place it in an oil tank. After placing the continuous PCS fiber in an oven at 200°C for 2 hours, the degree of non-melting reaction (calculated based on the reaction consumption of Si-H bonds in PCS) is 65%, and the gel content in xylene is 86%. . Put 5 bundles of continuous PCS non-melting fibers obtained in this way into the oiling and bundling device, and then pass through the oil tank for oiling and bundling, and then dry them in a drying oven (temperature 120°C, time 1h), and then pass through them with high-purity nitrogen gas (Purity 99.995%) protected high-temperature furnace (furnace temperature 1300°C), fired at a high temperature at a wire speed of 0.5m / min, wound on the upper drum, and obtained continuous SiC fiber

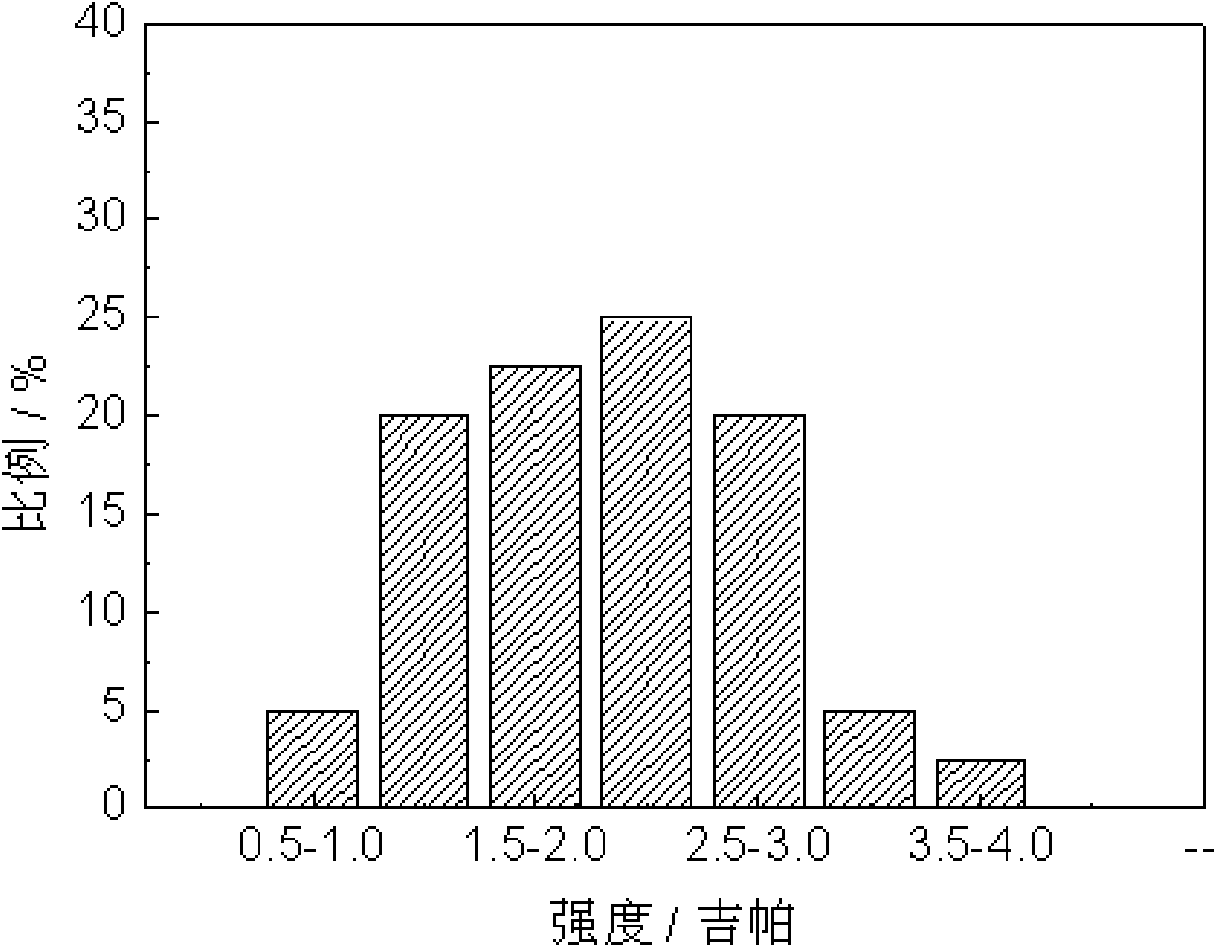

[0040] The broken end rate of the fiber was measured to be 3.9%, an...

Embodiment 2

[0043] Take 30% epoxy-modified silicone oil emulsion (referred to as EMPS according to its English abbreviation, pH=7.0, viscosity is 5mPa.s) 3g and dissolve in 180ml distilled water, stir at 300rpm for 1 hour to make the concentration about 0.5 % uniform emulsion, placed in the oil tank. 5 bundles of continuous PCS non-melting fibers after non-melting treatment under the same conditions as in Example 1 were continuously oiled and bundled in an oil tank, then dried in a drying furnace, and then degummed in a degumming furnace (processing temperature 700 ° C) and then wound on the upper cylinder To obtain continuous PCS bundled fibers, place the non-melting fibers in a high-temperature furnace, heat them to 1000°C for 1 hour under the protection of high-purity nitrogen at a heating rate of 150°C / hour, take them out after cooling to room temperature, and press 0.5m / h The wire-feeding speed of min enters the 1300 ℃ high-temperature furnace protected by high-purity nitrogen for fi...

Embodiment 3

[0046] Dissolve 3 g of polyether modified silicone oil (PMPS according to its English abbreviation, purity 98%, pH=7.0, viscosity 2000 mPa.s) in 300 ml distilled water, stir evenly, and place it in an oil tank. Five bundles of the same continuous PCS non-melting fibers as in Example 1 were oiled, bundled, dried and fired at a high temperature of 1300°C according to the process flow of Example 1 to obtain continuous SiC fibers.

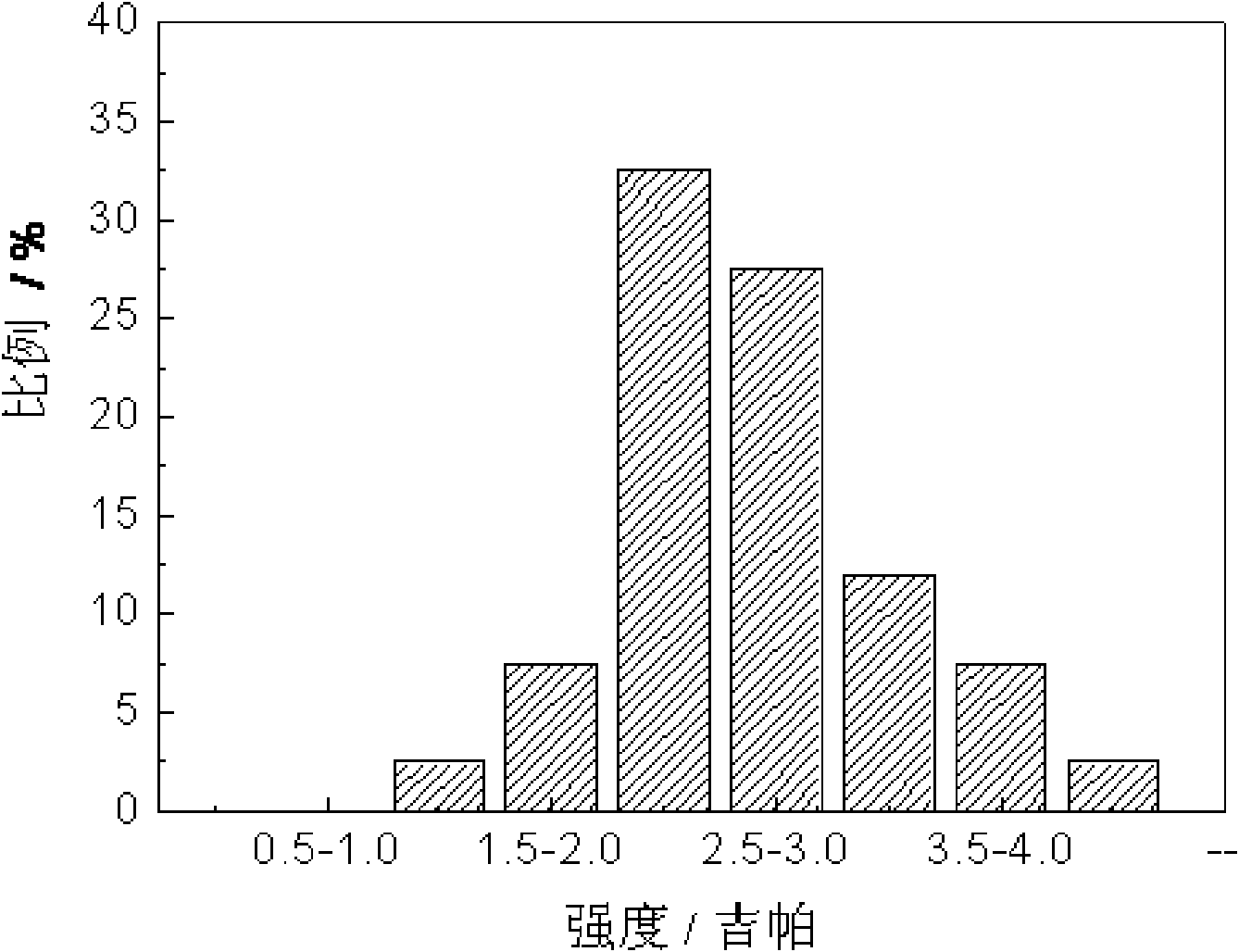

[0047] The measured fiber breakage rate was 4.1%, the average fiber diameter was 13.2 μm, the average tensile strength was 2.47GPa, and the C.V value of the tensile strength distribution was 23.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com