Method for preparing evanescent wave coupling type single carrier traveling wave photoelectrical detector

A technology of photodetector and manufacturing method, which is applied in the coupling of optical waveguide, optical waveguide light guide, light guide, etc., and can solve the problems of reducing bandwidth performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

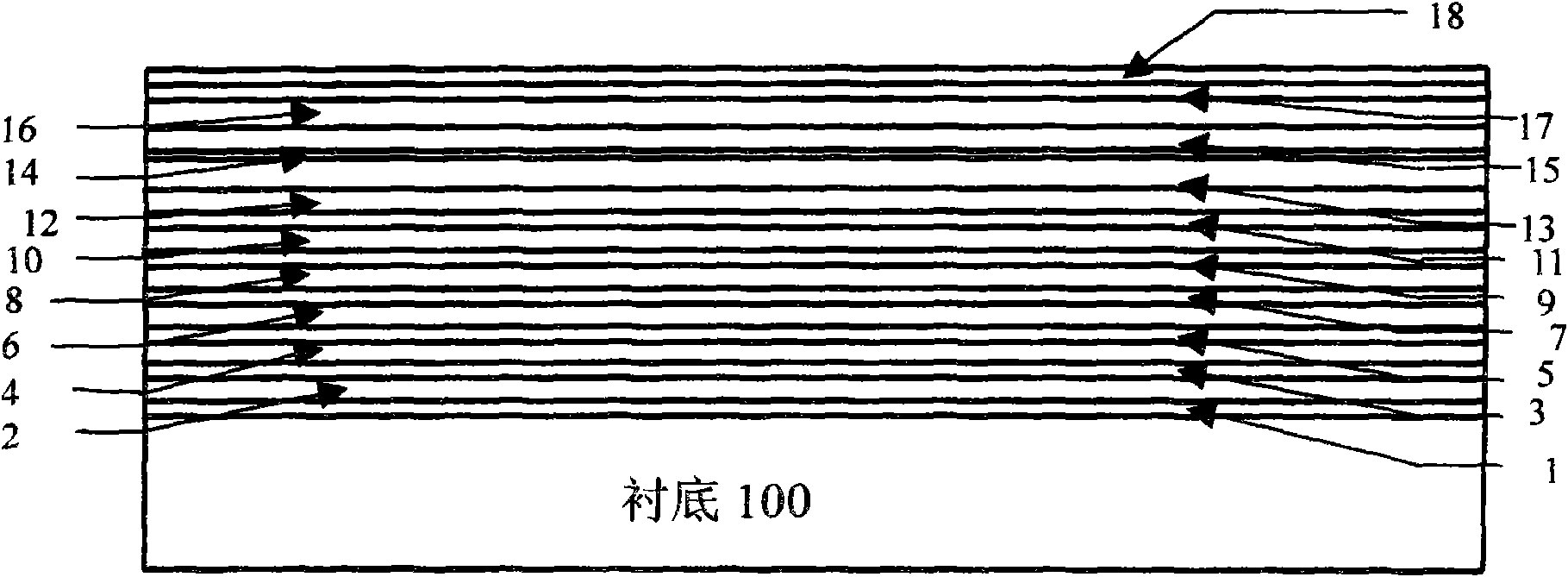

[0027] figure 1 It is a schematic cross-sectional view of one epitaxy on half of the insulating indium phosphide substrate 100 by metal-organic vapor deposition. On the semi-insulating InP substrate 1, a 100nm-thick InP stress buffer layer 1 is first grown on the semi-insulating InP substrate 1 by metal-organic chemical vapor deposition (MOCVD), which is mainly to adjust the lattice mismatch; 5 cycles of 1.2Q quaternary layer / InP layer, 5 cycles of 1.2Q quaternary layer / InP layer are the first 1.2Q quaternary layer 2, the first indium phosphorus layer 3, and the second 1.2Q quaternary layer 4. The second indium phosphorus layer 5, the first n-1.2Q quaternary layer 6, the first n-indium phosphorus layer 7, the second n-1.2Q quaternary layer 8, the second n-indium phosphorus layer 9, the first n-indium phosphorus layer Three n-1.2Q quaternary layers 10, third n-InP layer 11, 1.2Q quaternary layer / InP layer thickness of 5 periods are all 190nm / 110nm, wherein the first 1.2Q quate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com