Method for preparing transparent thin-film transistor of alloyed oxide

A thin film transistor and transparent thin film technology, which is applied in the field of semiconductor single crystal thin film preparation, can solve the problems of insufficient flexibility of ZnO thin film, high carrier concentration and high annealing temperature, so as to improve field effect mobility, high mobility, The effect of low manufacturing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below through specific embodiment, further illustrate substantive characteristic and remarkable progress of the present invention.

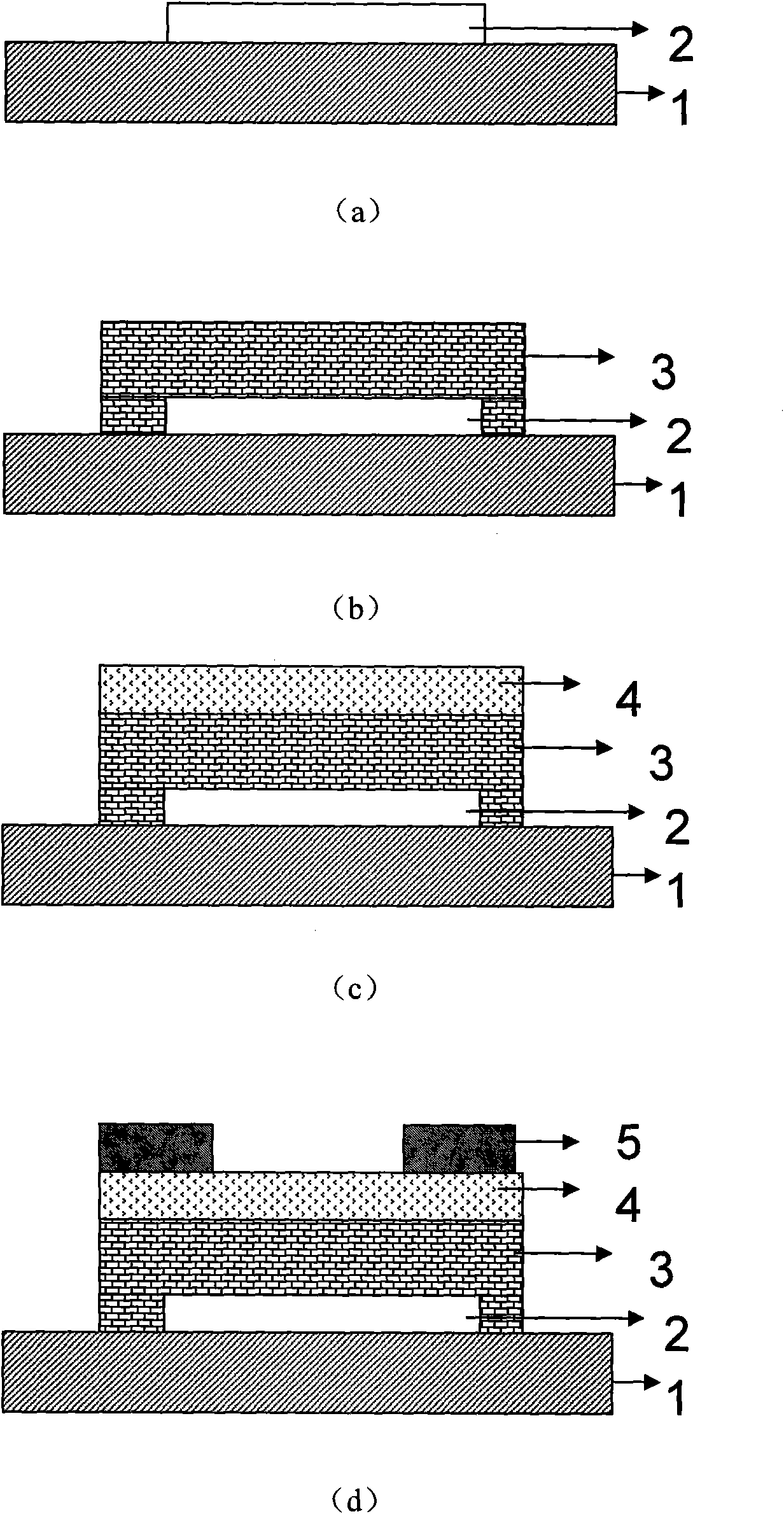

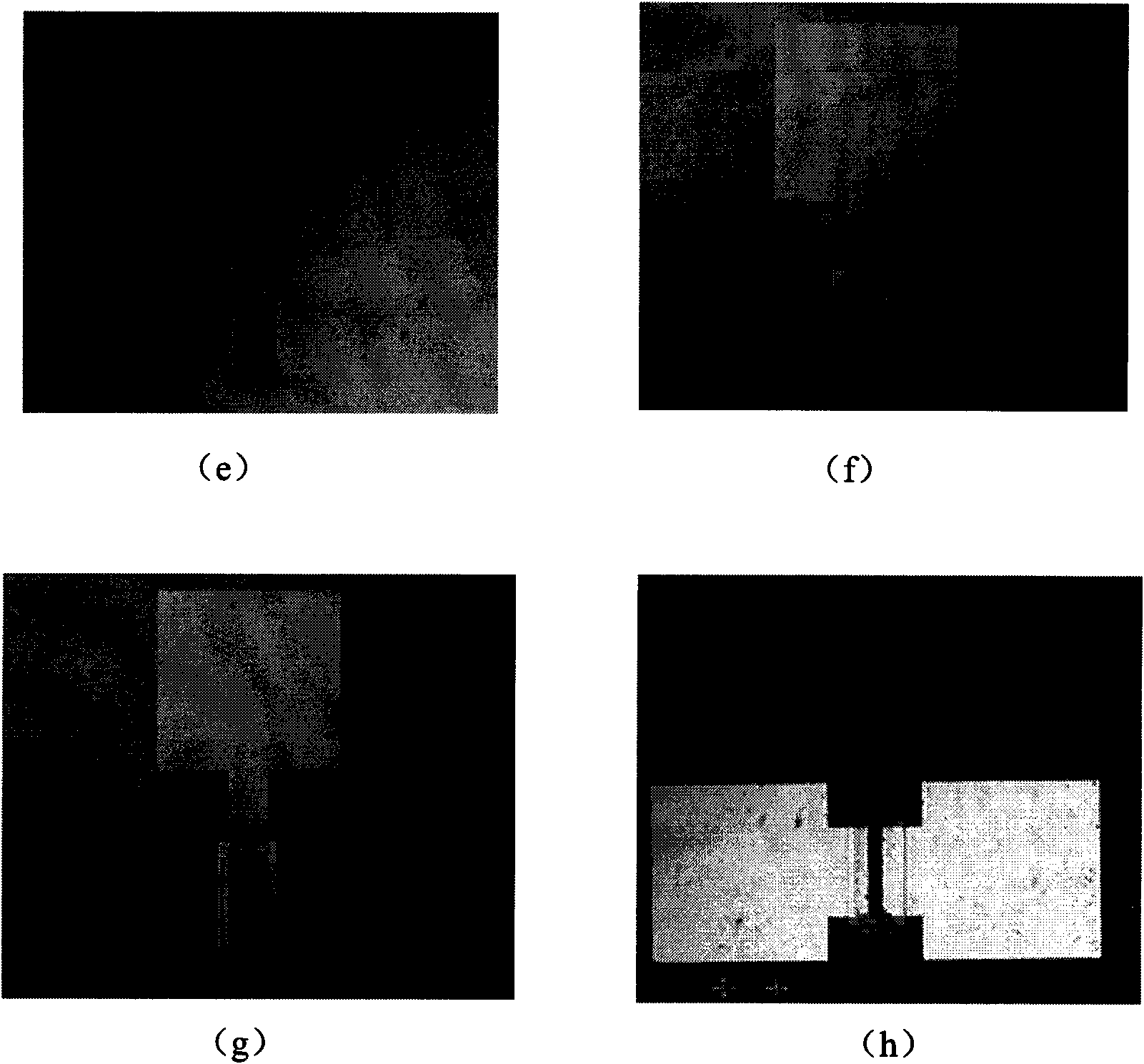

[0059] (1) photoetching ITO gate electrode 2, see figure 1 (a) and see figure 2 (e)

[0060] 1) Cleaning ITO glass 1, carbon tetrachloride, acetone, and alcohol ultrasonic cleaning three times, each for three minutes. Then rinse repeatedly with deionized water.

[0061] 2) Drying: Put the cleaned ITO glass into an oven and dry at 120°C for 30 minutes;

[0062] 3) Coating: Spray the photoresist on the ITO surface with a coating machine, the rotation speed of the coating machine is 6000 rpm, the coating is 40s, and the thickness of the coating is 1.1 μm;

[0063] 4) Pre-baking: put the ITO glass with the photoresist on it in an oven, and bake it at 80°C for 20 minutes;

[0064] 5) Exposure: UV exposure for 40s;

[0065] 6) Developing: a developer solution with a ratio of 1:1 (deionized water), the developing time is about 22s (the tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com