Method for preparing sulfur doped nanometer ZnO of various shapes

A technology of sulfur doping and nanotechnology, which is applied in the field of preparation of sulfur doped nano-ZnO, can solve the problems that the shape cannot be controlled, restricts the use of sulfur-doped ZnO, and the preparation process is complicated, and achieves low cost, sulfur The effect of high content and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~19

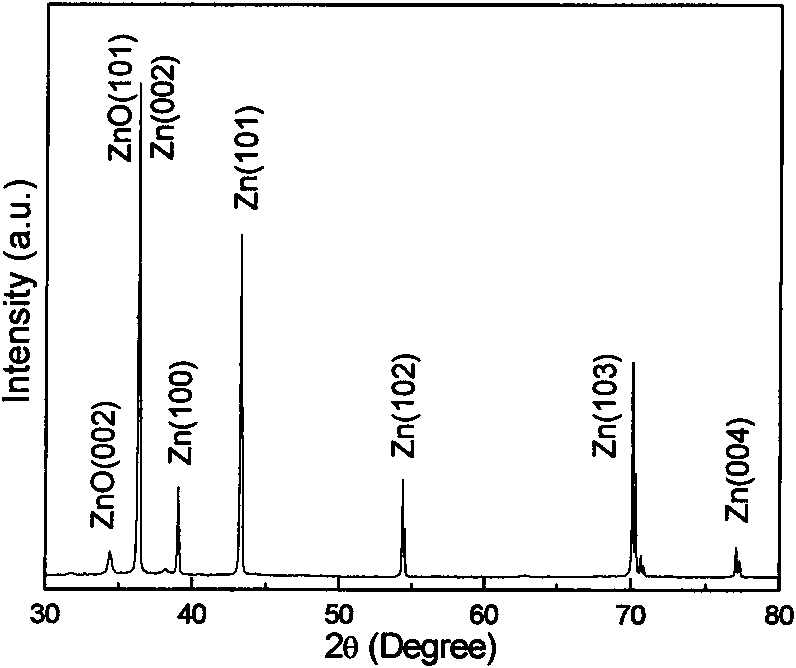

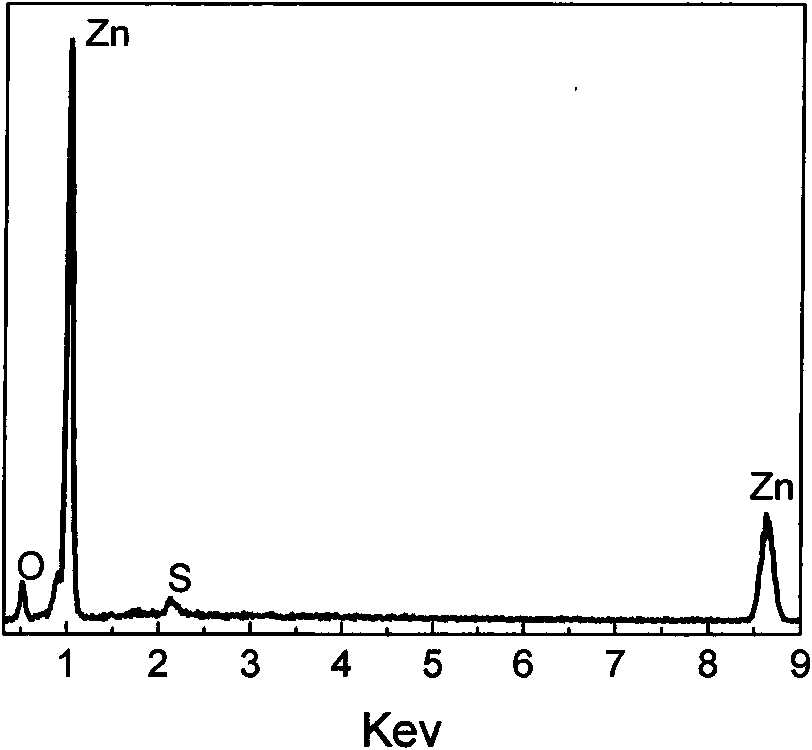

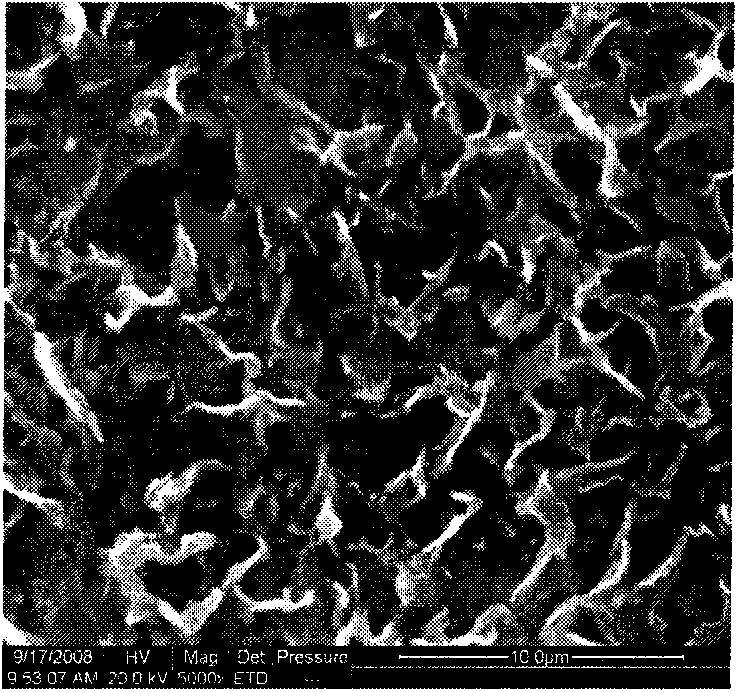

[0033] A method for preparing sulfur-doped nano-ZnO with various morphologies. The specific steps are: mixing a sodium thiosulfate solution with a concentration of 0.095M and a formamide solution with a concentration of 5% in a container, and the two in the mixed solution The volume ratio of the solution is 5-95:5-95. Put the zinc foil in the container, then cover the opening of the container, and place it in an oven at 60-70℃ to react for 18-30 hours. Take out the zinc foil and use it. Ionized water and ethanol are cleaned and dried. The specific parameters of Examples 1-19 and the morphology of the products are as follows:

[0034]

Example

Na 2 S 2 O 3 Solution

Parts by volume

Formamide solution

Parts by volume

Oven temperature (℃)

Reaction time

(Hour)

Product

1

5

95

65

24

Flake (small)

2

10

90

50

30

Flake (small)

3

15

85

65

24

Flake (large)

4

20

80

65

24

Flake (large)

5

25

75

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com