O-phthalodinitrile end-blocked soluble polyarylether resin with phthalazinone structure and condensate and preparation method thereof

A technology of phthalonitrile and naphthalenone biphenyl, which is applied in the field of polymer material synthesis, can solve the problems that the preparation method is unknown and does not involve the end-capped soluble polymer containing phthalonitrile group, etc. The effect of good molding performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

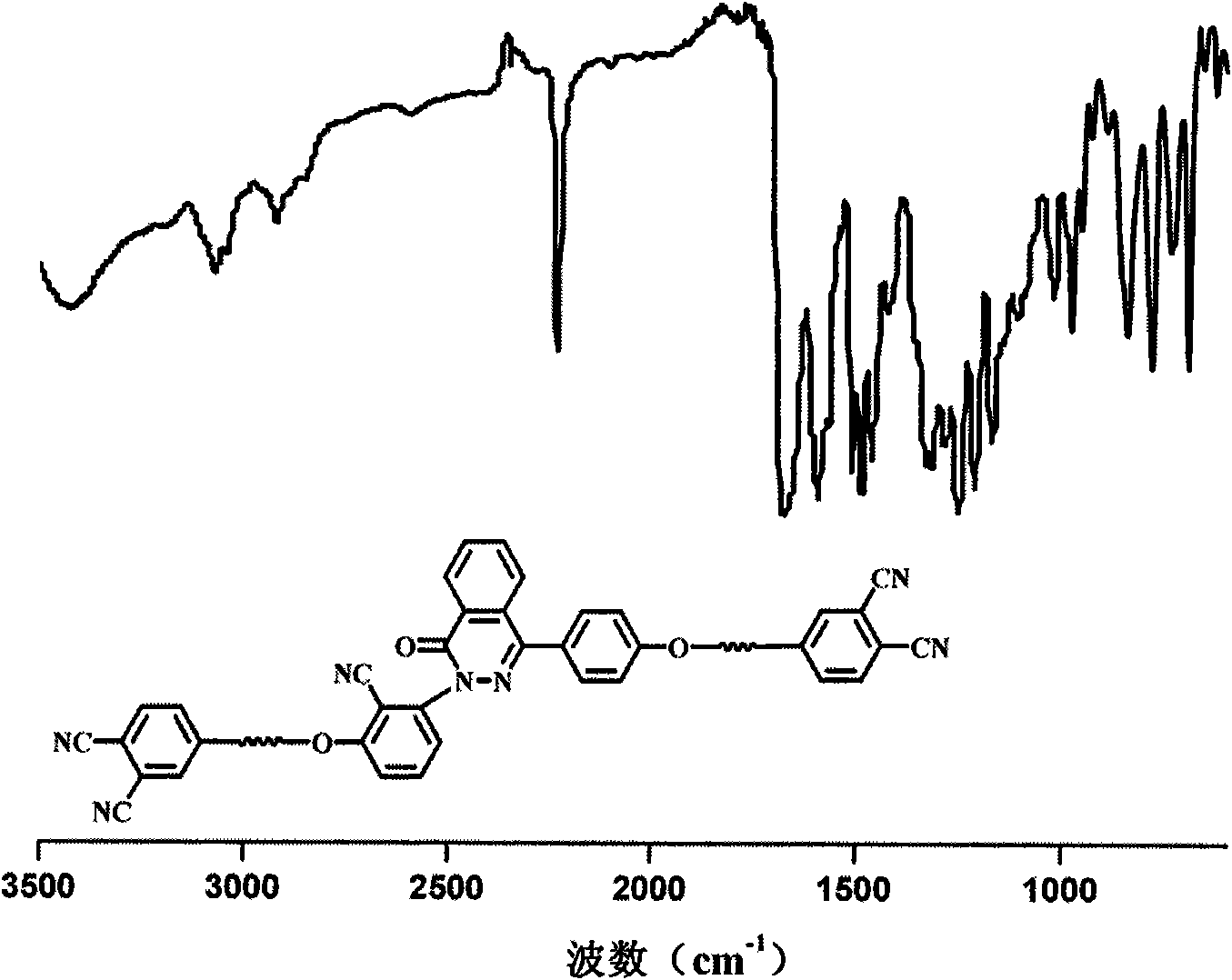

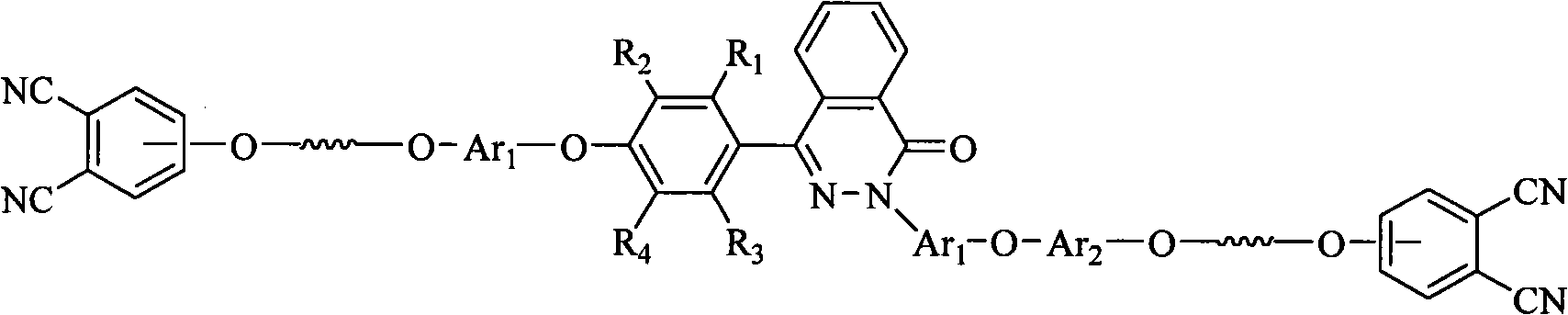

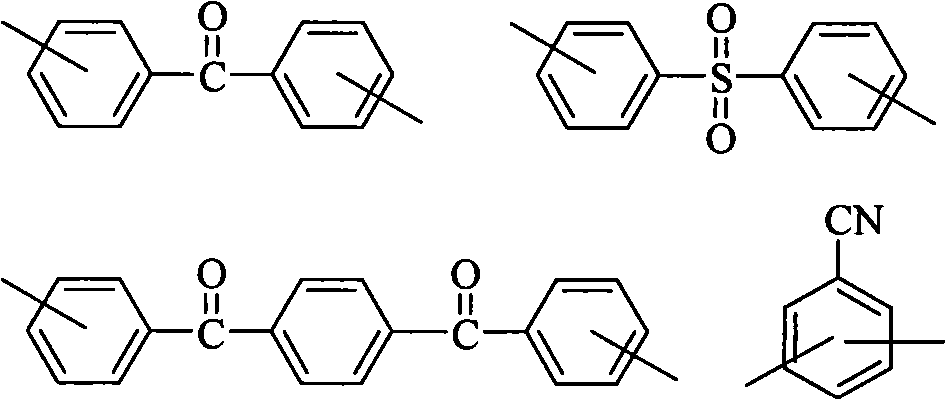

[0046] Example 1 Preparation and performance of polyarylether (nitrile sulfone ketone) and cured product containing double-terminated phthalonitrile and phthalazinone biphenyl structure

[0047] Add 2.5 parts of 4-(4-hydroxy-phenyl)-2H-phthalazin-1-one, 2.6 parts Anhydrous potassium carbonate, 2,6-dichlorobenzonitrile, 4,4'-dichlorodiphenyl sulfone, 4,4'-dichlorobenzophenone or their mixtures total 2.0 parts, toluene and dimethyl sulfoxide . Under nitrogen atmosphere, after azeotropic reflux of toluene with water, the temperature was raised to 180°C for about 3 hours, and then cooled down. Then add 1.0 parts of 4-nitrophthalonitrile, react at room temperature for 6 hours, and then raise the temperature to 80°C for 12 hours. Under high-speed stirring of the polymer solution, boiling water is used as a precipitating agent, the polymer is subjected to sedimentation, deionized water repeatedly washing and drying, and vacuum drying to obtain double-terminated phthalonitrile and p...

Embodiment 2

[0057] Example 2 Preparation and properties of polyarylene sulfide (nitrile sulfone ketone) and cured product containing double-ended double-ended phthalonitrile and phthalazinone biphenyl structure

[0058] In a dry 100mL three-necked flask equipped with mechanical stirring, reflux condenser, water separator and air duct, add 4-(4-hydroxy-phenyl)-2H-phthalazin-1-one and 4,4- A total of 2.5 parts of dihydroxydiphenyl sulfide, 2.6 parts of anhydrous potassium carbonate, 2,6-dichlorobenzonitrile, 4,4'-dichlorodiphenyl sulfone, 4,4'-dichlorobenzophenone or their The mixture was 2.0 parts total, toluene and dimethyl sulfoxide. Under nitrogen atmosphere, after azeotropic reflux of toluene with water, the temperature was raised to 180°C for about 3 hours, and then cooled down. Then add 1.0 parts of 4-nitrophthalonitrile, react at room temperature for 6 hours, and then raise the temperature to 80°C for 12 hours. Under high-speed stirring of the polymer solution, boiling water is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com