Method for preparing trapezoidal phenyl polysiloxane

A technology of phenyl polysiloxane and trapezoid is applied in the field of preparation of trapezoidal phenyl polysiloxane, which can solve the problems of high cost and complicated synthesis process, and achieve simple reaction steps, strong operability, and easy industrialization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

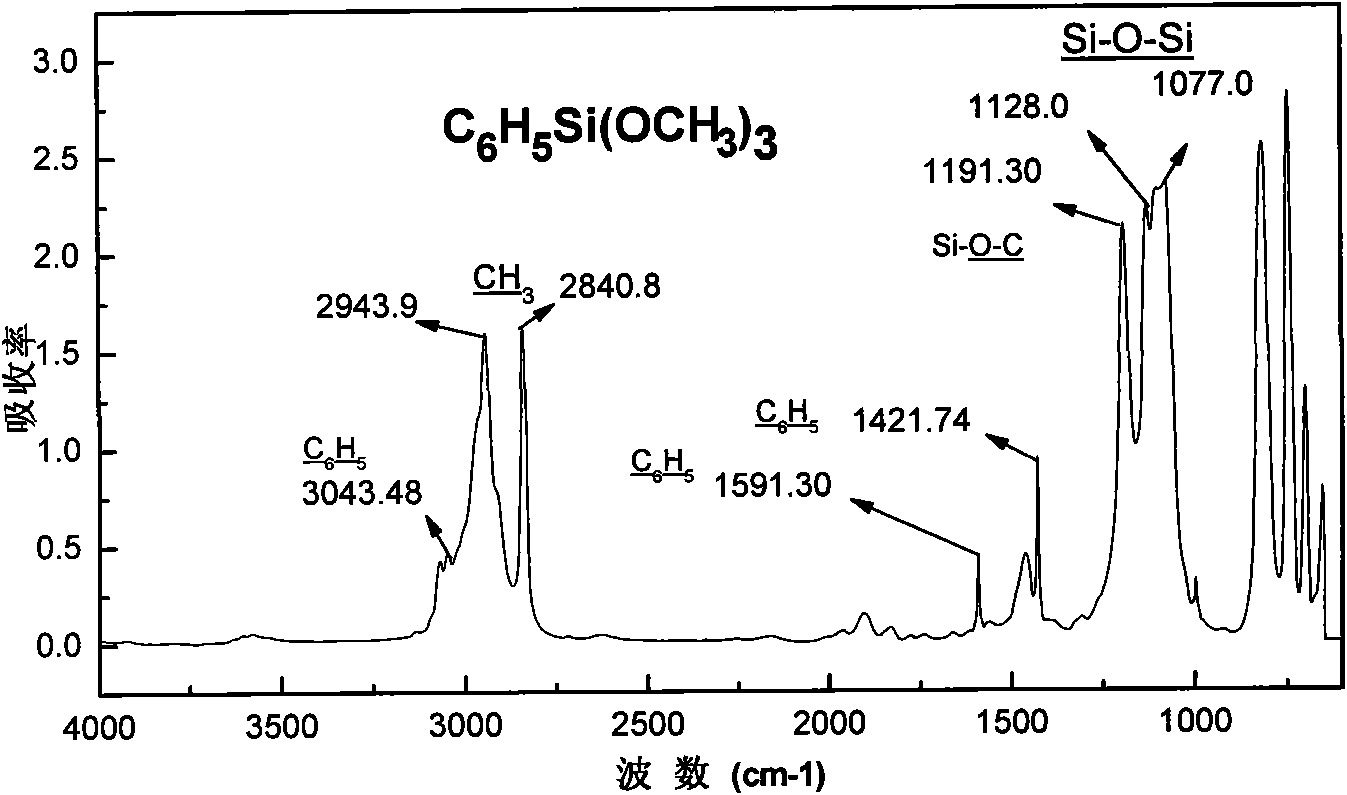

[0033] 1) 10ml (0.054mol) phenyltrimethoxysilane (C 6 h 5 Si(OCH 3 ) 3 ) after being dissolved in 60ml of toluene (the concentration of the monomer in the solvent is 1mol / kg), stirring and adding dropwise 15ml (0.833mol) of water and 0.151ml of a mixed solution of mass concentration of 36.5% hydrochloric acid at a rate of 2 drops / min (PH=3) at the same time (the molar ratio of water and monomer is 15:1), react at 10°C for 24h;

[0034] 2) The reaction solution in step 1) was allowed to stand for stratification, and after removing the lower aqueous phase, the upper toluene phase was washed with ultrapure water until the pH of the washing solution was ≈7;

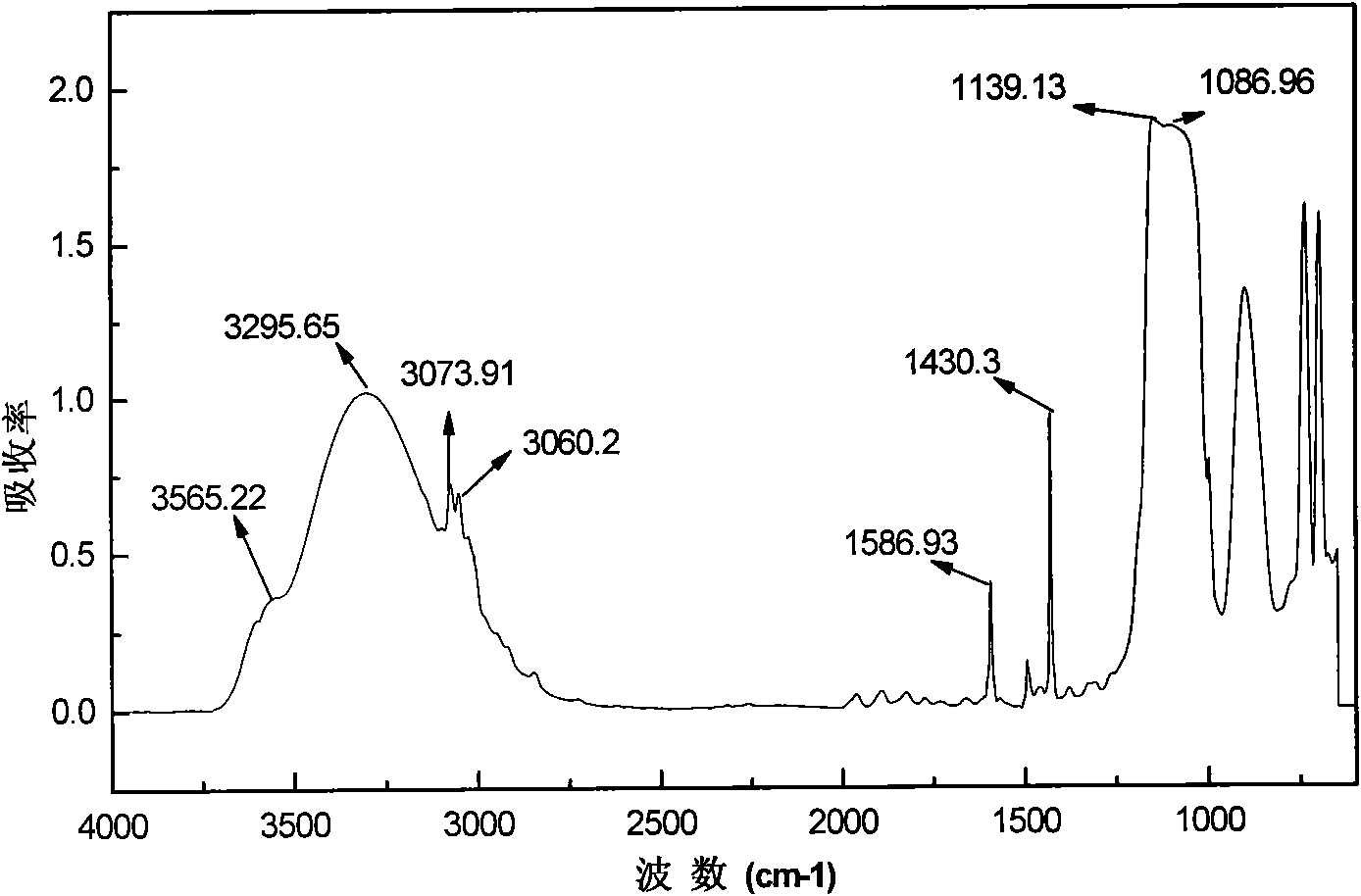

[0035] 3) Rotate the excess solvent in the toluene phase after washing with water and add 2ml of methanol solution (PH=13) of KOH with a concentration of 1g / ml (the consumption of the basic catalyst is 5wt% of the oil phase system after washing), in Reflux at 80°C for 8h;

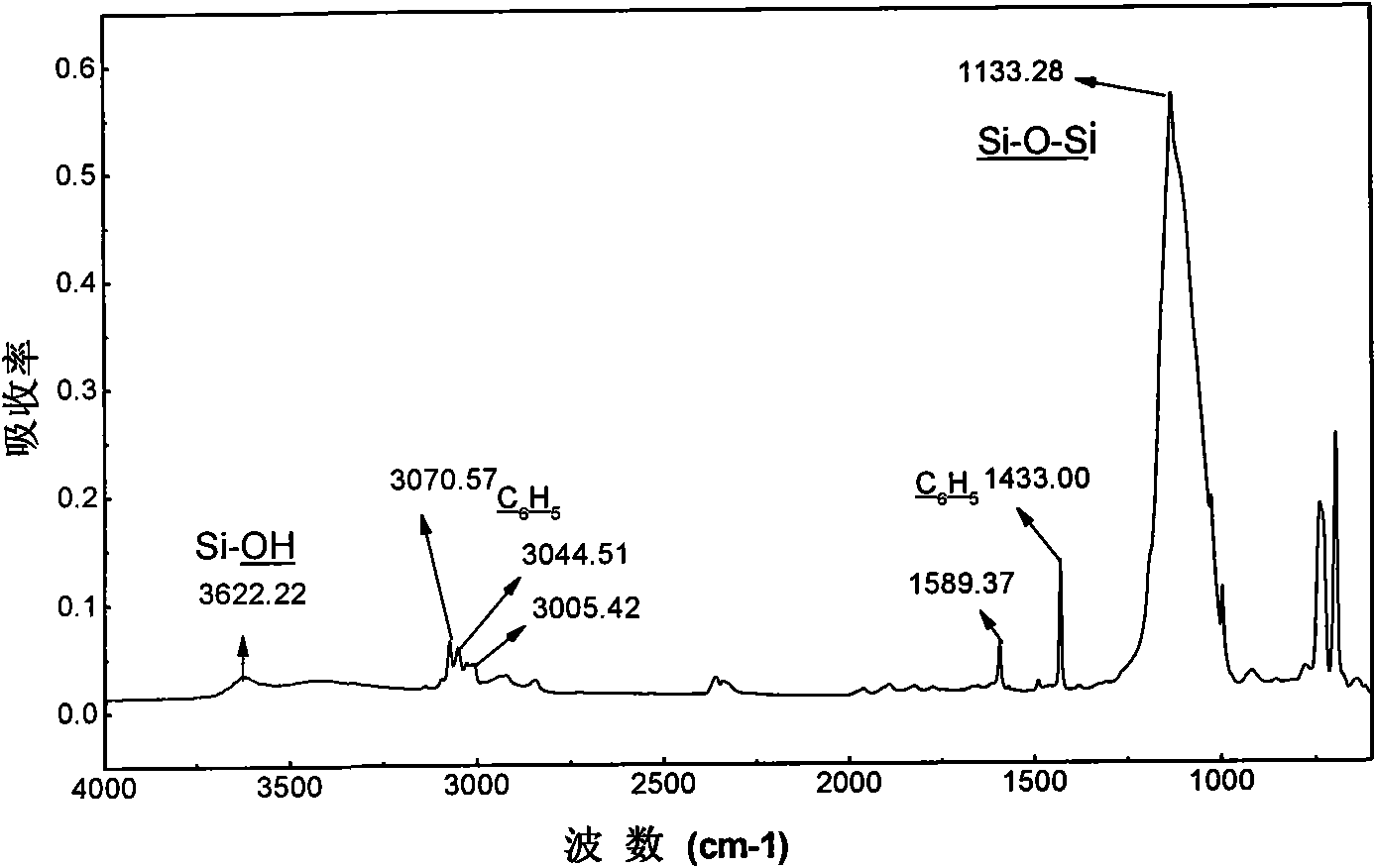

[0036] 4) After concentrating the polymer organ...

Embodiment 2

[0038] 1) 10ml (0.054mol) phenyltrimethoxysilane (C 6 h 5 Si(OCH 3 ) 3) was dissolved in 60ml of toluene (the concentration of the monomer in the solvent was 1mol / kg), stirred and added dropwise at a rate of 2 drops / minute a mixture of 9.72ml (0.54mol) water and 0.1ml mass concentration of 36.5% hydrochloric acid Solution (PH=3) at the same time (the molar ratio of water and monomer is 10:1), react at -15°C for 10h;

[0039] 2) with step 2) in embodiment 1;

[0040] 3) Rotate the excess solvent in the toluene phase after washing with water and add 2ml of methanol solution (PH=13) of KOH with a concentration of 1g / ml (the consumption of the basic catalyst is 5wt% of the oil phase system after washing), in Reflux at 25°C for 5h;

[0041] 4) After concentrating the polymer organic solution by rotary evaporation, add 2 times the volume of the concentrated solution to precipitate methanol, and vacuum-dry the precipitate to obtain white trapezoidal phenyl polysiloxane powder. ...

Embodiment 3

[0043] 1) 10ml (0.054mol) phenyltrimethoxysilane (C 6 h 5 Si(OCH 3 ) 3 ) was dissolved in 60ml of toluene (the concentration of the monomer in the solvent was 1mol / kg), stirred and added dropwise at a rate of 2 drops / minute a mixture of 5.832ml (0.324mol) water and 0.06ml mass concentration of 36.5% hydrochloric acid Solution (PH=3) at the same time (the molar ratio of water and monomer is 6:1), react at 0°C for 16h;

[0044] 2) with step 2) in embodiment 1;

[0045] 3) Rotate the excess solvent in the toluene phase after washing with water and add 2ml of methanol solution (PH=13) of KOH with a concentration of 1g / ml (the consumption of the basic catalyst is 5wt% of the oil phase system after washing), in Reflux at 60°C for 3h;

[0046] 4) After concentrating the polymer organic solution by rotary evaporation, add 2 times the volume of the concentrated solution to precipitate methanol, and vacuum-dry the precipitate to obtain white trapezoidal phenyl polysiloxane powder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com