The disadvantages of this invention are: 1. What the rice strengthens is

trace mineral nutrients, and the compound or mixing unit is very small, and the

dissolution and mixing methods of

calcium lactate and the like are not explained in detail.

By comparison, it can be seen that the content of

calcium,

selenium and iron in the mixed mineral nutrients of the invention product does not meet the national standards.

3. The process of washing rice will cause the loss of enhanced nutrients

[0004]

Chinese Patent Publication No. CN2413514Y, on January 10, 2001, disclosed the invention of "Enhanced Rice with Systemic

Nutrition", which is characterized in that the rice includes puffed micropores on the rice, and the dissolved and / or insoluble ingredients contained in the puffed micropores The superfine

powder nutritional agent is realized by expanding the rice particles quantitatively to form expanded micropores, soaking the

nutrient solution into the micropores and

drying them, and then using

pectin to penetrate into the surface of the rice to form a protective film. Spray glue paste and / or

pectin etc. to form the outer protective film layer. Its disadvantages are: 1. The variety and content standard of the

nutrient solution are not disclosed, so it is difficult to determine the

nutritional quality of the product

After cooking, the puffed micropores will increase and expand, the rate of whole rice is low, and the rate of

broken rice is high, which is difficult for consumers to accept

3. Although the outer layer of rice has a protective film, the process of washing rice will still cause the loss of added nutrients

The weak point that two formulas exist is: 1,

vitamin B 2 The properties are orange-yellow, slightly smelly, slightly bitter, and the smell is very strong, which affects the sensory and taste of rice products

2. The mineral nutrient formula lacks the

selenium element that most of the

human body lacks and needs to be supplemented

3. The specific varieties of mineral elements are not specified in accordance with the requirements of relevant laws and regulations, because some varieties are prohibited from being added to rice or cereal products

The weak point that this method exists is: 1, secondary spraying dips in the

nutrient solution process, does not provide the implementation mode of controlling rice fortified

nutrient content, thus, is difficult to guarantee the stability of each

monomer nutrient content index in rice

2. No washing process and

sanitation requirements for rice are given, and the process of washing rice before cooking will inevitably result in the loss of added nutrients

3. The rice after spraying is dried naturally for 1 hour, which has low production efficiency and high cost, which is not conducive to industrial production

4. When the rice in the process is sprayed with nutrient solution in the spray cabin, it is difficult to achieve the effect of slow

dryingThe disadvantages of this method are: 1. Quantitatively putting rice and nutrient solution into one or more mixing devices is not suitable for industrial production. Manual quantification may lead to unstable addition of nutrient solution and affect the stability of

nutrient content indicators.

2. The stirring (gelatinization) process at 50°C for 5 to 10 minutes changes the natural structure and taste of rice, which is difficult for consumers to accept

3. There is no rice washing-free process and

hygiene requirements, and the rice washing process will inevitably result in the loss of added nutrients

The

disadvantage of the spraying device for rice nutritional enhancement described in this method is that a spraying device can realize the three functional requirements of nutrient solution spraying, slow

drying, and soaking solution for rice under the conditions of the

work flow, and the result may not be good. ; Because the water-containing nutrient solution produces water droplet atomization and sprays rice through

gas pressure, the spraying device is rotating non-stop, and the

moisture content of rice increases and sticks to each other after being sprayed by liquid mist non-stop in this device, thus, it is difficult

Process requirements for slow drying and soaking solution

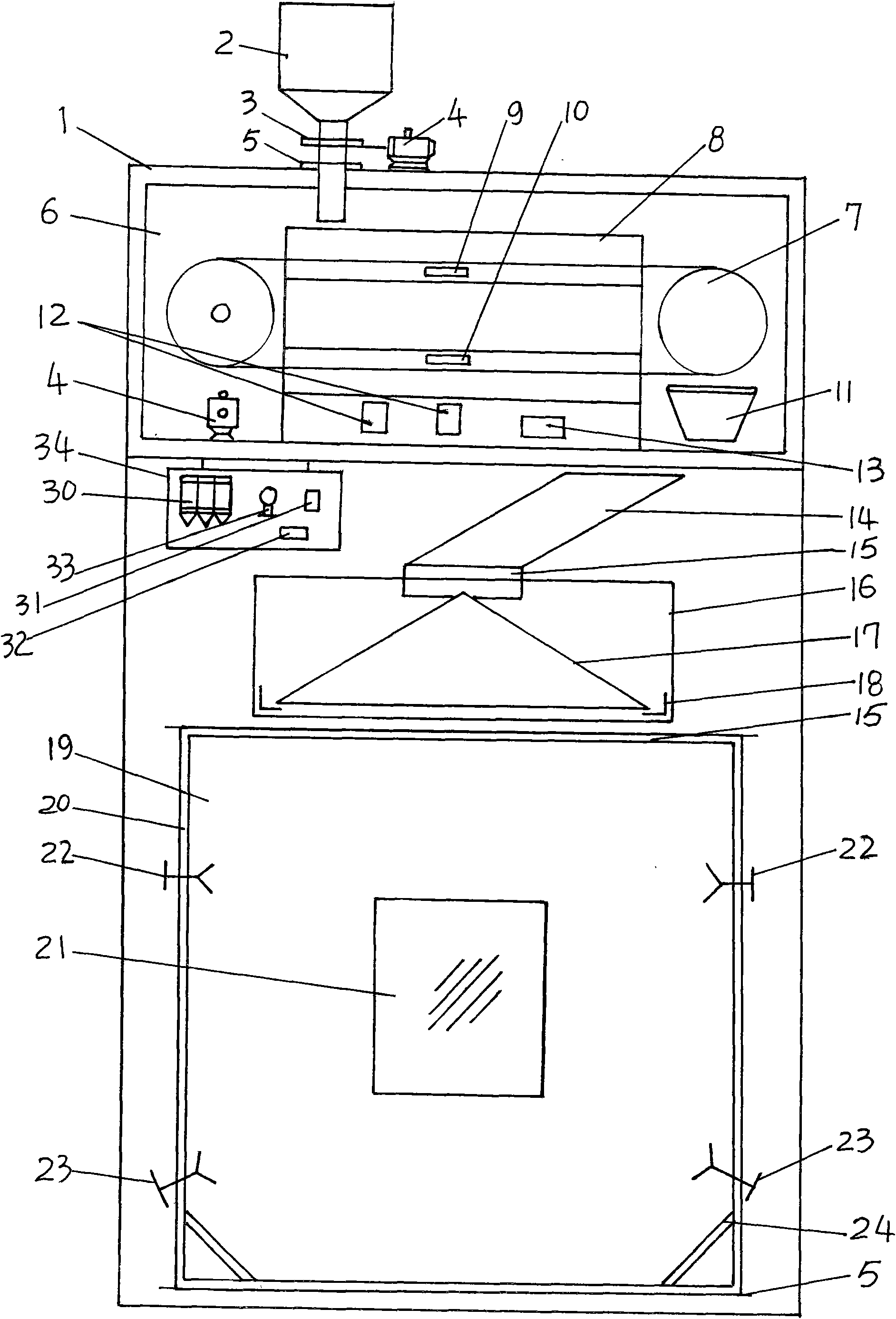

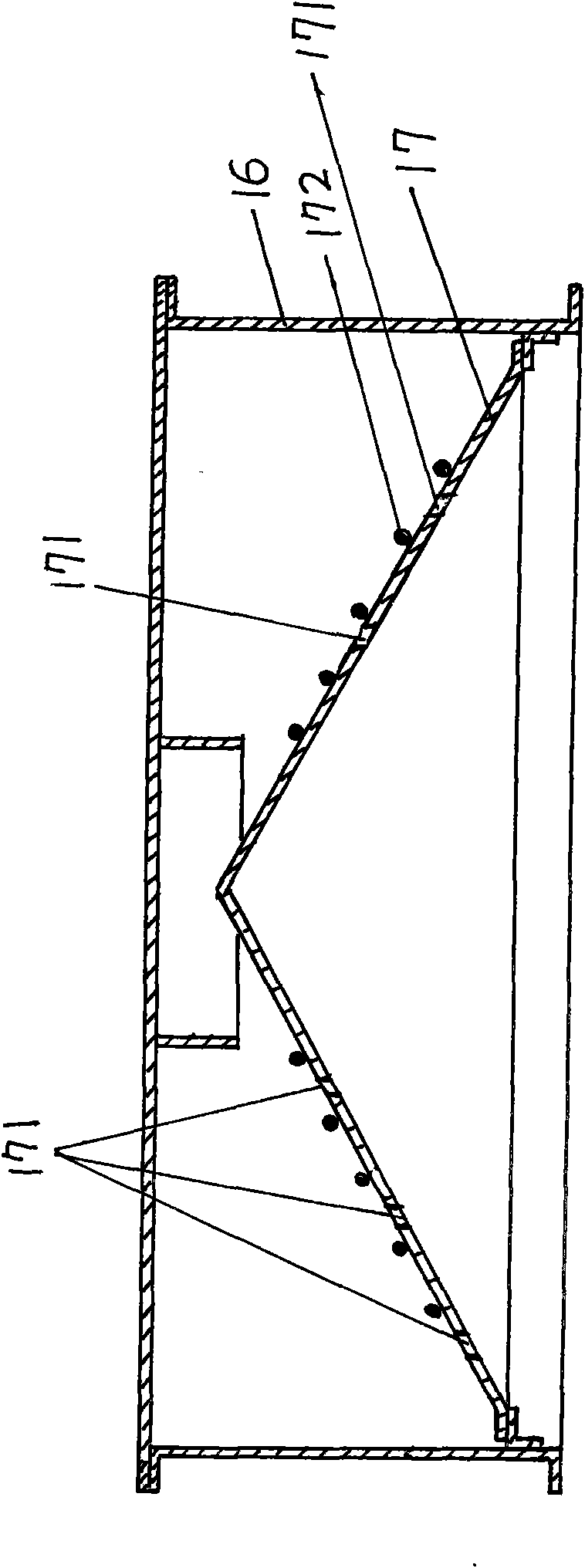

The atomizing

film applicator of the device is mainly composed of a circular box, two inlet and outlet flanges, a

rectifier, a decimeter, three fan nozzles, a 360° conical

nozzle and a receiving hopper. Disadvantages: 1. The rice falls directly from the feed port to the upper end of the cone-shaped

metal decimeter, which is easy to cause the whole rice to be broken and increase the

broken rice rate.

2. It is difficult for a

metal cone decimeter to disperse the rice hanging down in the bin body evenly. The distance from the atomized coating film to the

discharge port is short, and the rice scattered by the decimeter immediately passes through the atomized coating film and Falling into the

discharge port, it is difficult for the grains of rice to receive a uniform atomized coating, which can lead to unstable nutrient content indicators in the product

3. The upper feed port and the lower

discharge port of the atomized coating film can easily cause 30% to 60% loss of nutrient liquid mist and gas, and it is difficult to ensure the uniformity of the rice nutrient film

Login to View More

Login to View More  Login to View More

Login to View More