Cell sheet engineering and preparation method thereof

A tissue engineering, cell sheet technology, applied in biochemical equipment and methods, tissue culture, medical science, etc., can solve problems such as toxicity, adherence of cultured cells, deformation and damage of culture vessels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 Construction of corneal epithelial cell sheet

[0061] 1. Preparation of PNIPAm hydrogel grafted culture dish

[0062] (1) Recrystallized monomer

[0063] The purchased N-isopropylacrylamide monomer (N-isopropylacrylamide, NIPAAm) (Shanghai Wujing Technology Co., Ltd.) was recrystallized using benzene and isopropanol at a volume ratio of 1:1, and the recrystallized The NIPAAm monomer was dried for use.

[0064] (2) Preparation of monomer solution

[0065] Prepare a NIPAAm monomer solution with a mass concentration of 40%, containing a mass concentration of 0.1% cross-linking agent N, N'-methylene bisacrylamide (N, N-methylene bisacrylamide, MBA), all of which are passed through the solution isopropyl Alcohol preparation, shake and mix well before use.

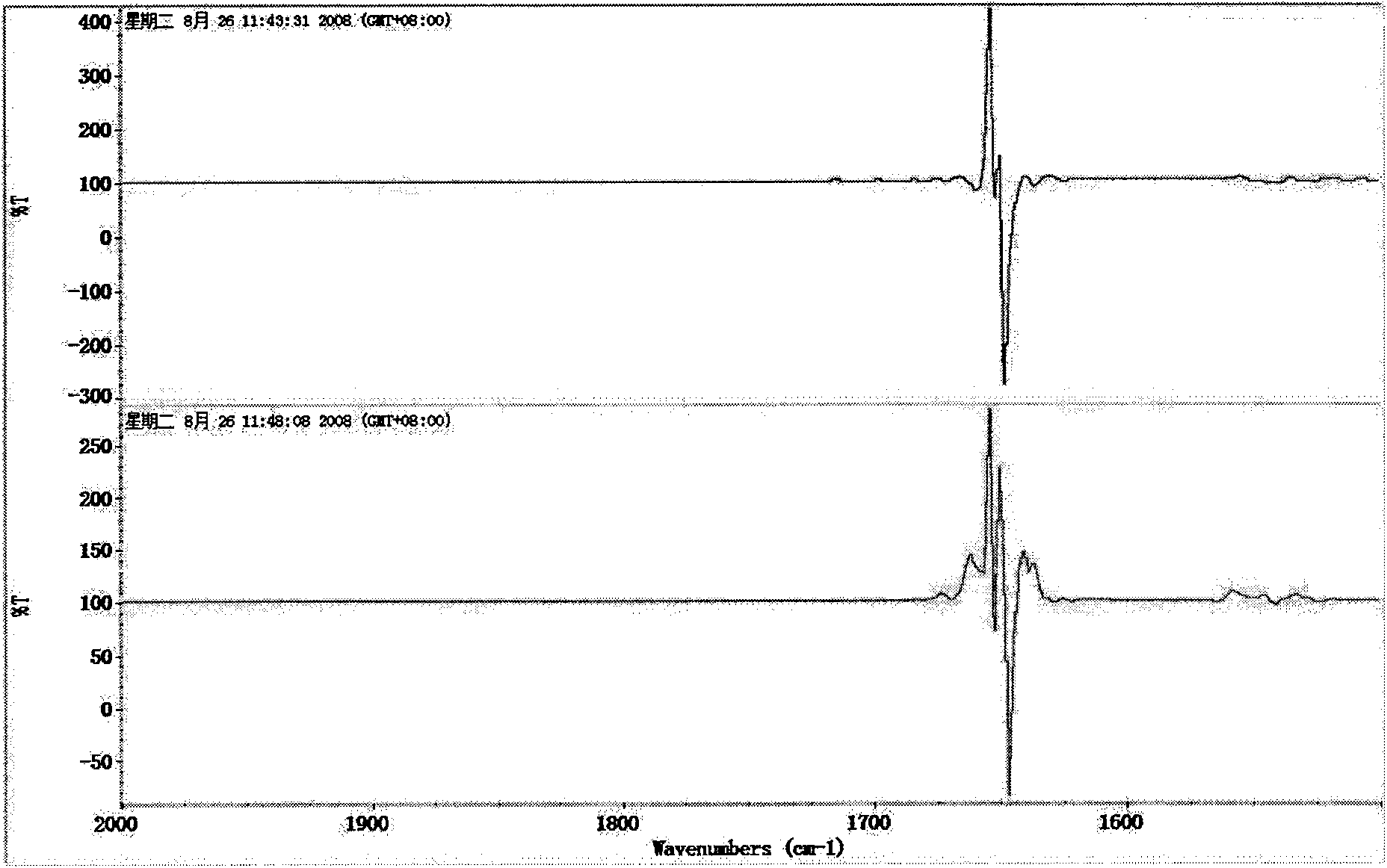

[0066] (3) Radiation Synthesis of Monomer Solution

[0067] Take the above-prepared NIPAAm monomer solution, add it to a 35mm tissue culture polystyrene (TCPS) culture dish, and spread it evenly on the ...

Embodiment 2

[0087] Embodiment 2 Construction of corneal epithelial cell sheet

[0088] 1. Preparation of PNIPAm hydrogel grafted culture dish

[0089] (1) Recrystallized monomer

[0090] With embodiment 1.

[0091] (2) Preparation of monomer solution

[0092] Prepare a NIPAAm monomer solution with a mass concentration of 60%, containing a mass concentration of 0.4% cross-linking agent N, N'-methylene bisacrylamide (N, N-methylene bisacrylamide, MBA), all of which are passed through the solution isopropyl Alcohol preparation, shake and mix well before use.

[0093] (3) Radiation Synthesis of Monomer Solution

[0094] Take the above prepared NIPAAm monomer solution and add it to the surface of the MILLICELL-CM insert culture dish [diameter: 30 mm, pore size: 0.4 μm, polytetrafluoroethylene (PTFE) (Millipore Company, USA) filter material] On the surface of the culture vessel, it is spread evenly on the surface of the culture vessel by the tension of the monomer solution itself. The cov...

Embodiment 3

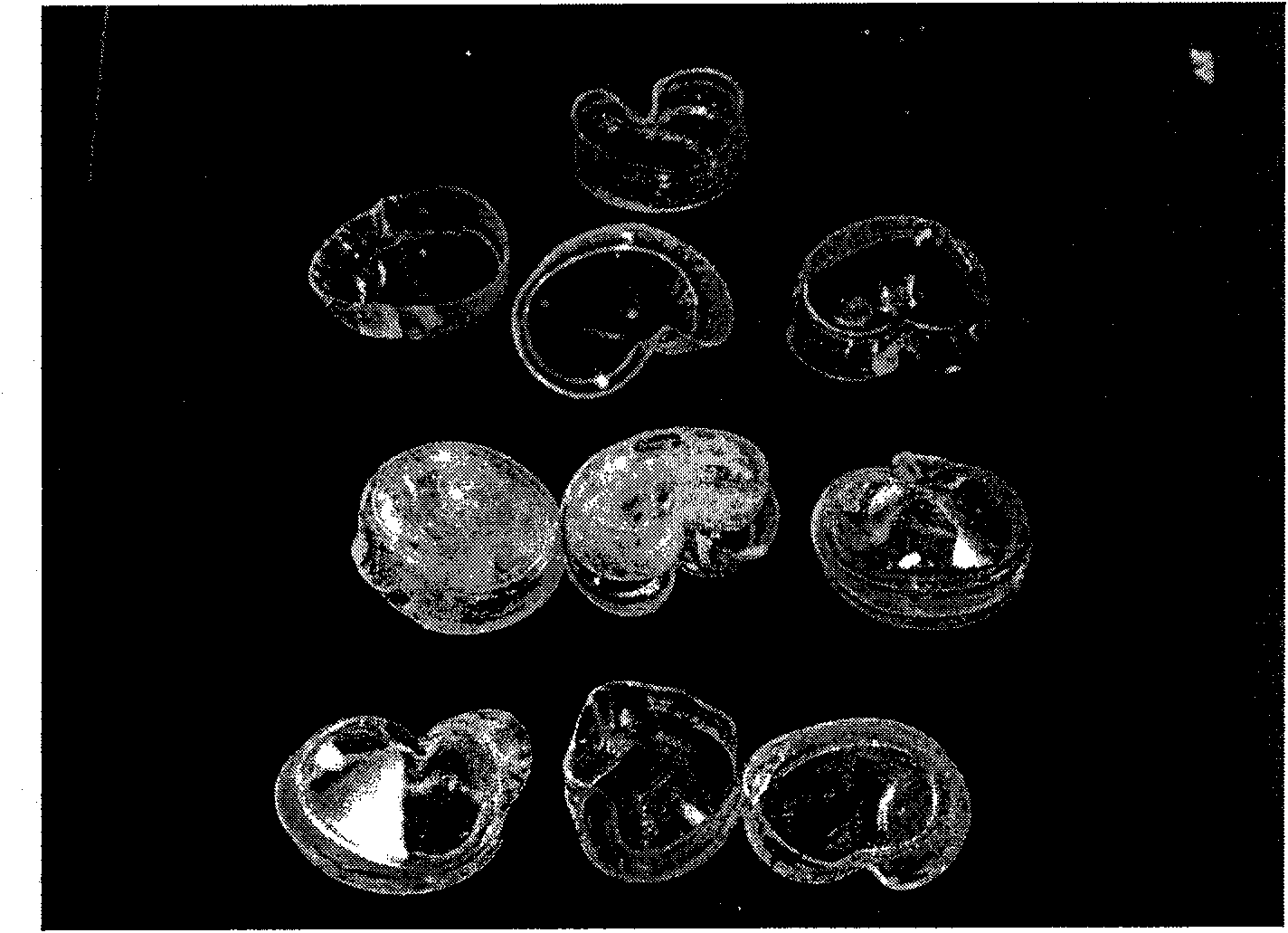

[0111] Example 3 Corneal endothelial cell sheet

[0112]The seed cell culture was carried out according to the conventional culture method of corneal endothelial cells, and the corneal endothelial cell sheet was constructed by a method similar to the construction of the corneal epithelial cell sheet described in Example 1 or 2. Corneal endothelial cell sheet transplantation can treat patients with corneal endothelial cell lesions and endothelial cell function decompensation: remove the diseased corneal posterior lamellar and corneal endothelial layer, through similar penetrating keratoplasty, deep lamellar corneal endothelial Corneal endothelial cell sheet transplantation is performed by surgical methods such as elastic membrane stripping and corneal endothelial transplantation. Corneal endothelial cell sheet transplantation usually does not require sutures, and the tissue adhesion between the cell sheet adhesion protein and the posterior corneal lamina is used to achieve cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com