Special refractory and acid-resistant brick and its preparation method

An acid-resistant brick and refractory technology, applied in the field of refractory materials, can solve the problems that the compressive strength and thermal shock stability at room temperature cannot be well met, and the higher requirements for the performance of refractory and acid-resistant bricks, and achieve low porosity and acid erosion resistance. Strong, high volume density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of special refractory and acid-resistant brick and its preparation method

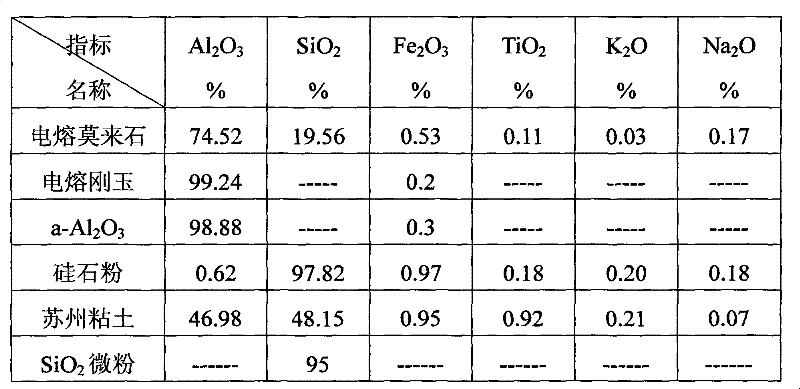

[0028] The raw material formula of special refractory and acid-resistant bricks (expressed in weight percentage):

[0029] Fused Mullite 20%, Fused Corundum 20%, a-Al 2 O 3 20%, Suzhou Clay 10%, Silica 15%, Talc 10% and SiO 2 Micronized 5%.

[0030] Preparation method of special refractory and acid-resistant bricks:

[0031] According to the raw material ratio of the above-mentioned special refractory and acid-resistant bricks, the ingredients and binders are prepared, that is, the sulfite pulp waste liquid (the specific gravity of the sulfite pulp waste liquid is 1.25g / cm2). 3 ) into the wheel mill for mixing and milling. The mixing time is 20 minutes. The amount of sulfite pulp waste liquid added accounts for 4% of the total raw material. After mixing and milling, the material is trapped for 24 hours. The machine is formed into bricks, the forming pressure of the pres...

Embodiment 2

[0032] Embodiment 2: It is basically the same as Embodiment 1, and the difference is:

[0033] The raw material formula of special refractory and acid-resistant bricks: 50% fused mullite, 10% fused corundum, a-Al 2 O 3 15%, Suzhou Clay 5%, Silica 10%, Talc 4% and SiO 2 Micronized 6%.

[0034] The preparation method of the special refractory and acid-resistant brick is basically the same as that of the first embodiment, except that the mixing time is 15 minutes, the amount of sulfite pulp waste liquid added accounts for 3% of the total raw materials, and the trapping time is 22 hours. The molding pressure of the press was 370 tons, the drying temperature was 120°C, the drying time was 14 hours, the firing temperature was 1550°C, and the holding time was 10 hours.

Embodiment 3

[0035] Embodiment 3: It is basically the same as Embodiment 1, and the difference is:

[0036] The raw material formula of special refractory and acid-resistant bricks: fused mullite 30%, fused corundum 15%, a-Al 2 O 3 10%, Suzhou Clay 12%, Silica Powder 20%, Talc Powder 8% and SiO 2 Micronized 5%.

[0037]The preparation method of the special refractory and acid-resistant brick is basically the same as that of the first embodiment, except that the mixing time is 10 minutes, the amount of sulfite pulp waste liquid added accounts for 5% of the total amount of raw materials, and the trapping time is 26 hours. The molding pressure of the press was 350 tons, the drying temperature was 150°C, the drying time was 11 hours, the firing temperature was 1500°C, and the holding time was 11 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com